Keep on Truckin'

Nothing ruins your day more than losing a vital exhibit component to the shipping gods. But when that item is actually an entire booth - or worse, the booth you've promised to erect for a brand new client from which you hope to win future business - then your day is about as bad as it'll get. Nothing ruins your day more than losing a vital exhibit component to the shipping gods. But when that item is actually an entire booth - or worse, the booth you've promised to erect for a brand new client from which you hope to win future business - then your day is about as bad as it'll get.

In 2000, I was a sales rep for an exhibit house in Southern California. One of my clients, a retail-apparel manufacturer based in Virginia, had recently hired a different exhibit house to design and build his 8-by-20-foot custom-rental exhibit. However, he wanted my company to install the new booth at a show in Long beach, CA, and since I lived near the convention center at the time, he wanted me to oversee installation.

Despite the rather odd situation, everything was going according to plan as I headed to the exhibit hall for the two-day installation. But when I reached my client's booth space, I found nothing but a slab of concrete. No crates. No graphics. No nothing.

After finding no sign of the exhibit in the nearby aisles or loading docks, I called the builder to determine if the booth was on its way. The reps there assured me it had been loaded onto

a semi several days before.

I called the freight company, expecting to discover a lost driver or a truck that had suffered a flat tire. I was surprised when the freight-company rep couldn't immediately report the shipment's whereabouts. In fact, the rep told me she'd call me back as soon as my booth was located. So I hung up the phone and waited.

With no news by the end of the day, I had to consider other options. I hated to even think about the arduous task of replacing a custom exhibit I hadn't designed or built. But I also didn't want to disappoint this client

on our first show together.

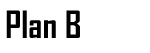

The next morning - with less than 24 hours before the show opened - the freight company finally called. The truck with my booth had broken down on the road. But rather than calling for help, the driver decided to simply abandon his vehicle and walk to the nearest town, where he'd hunkered down until morning. After a good night's rest, he finally called the freight company to report the problem. Bottom line, there was no way the booth would arrive in time for the show in Long Beach.

Sensing an opportunity (my company had lost the bid for the client's custom rental exhibit, but we hoped to get its booth-building business in the future), I figured we could make significant inroads to secure future business if I could solve this mishap. Unfortunately, with the clock ticking, I still had to find, not to mention set up, a replacement exhibit.

I began by having copies of the exhibit renderings and blueprints faxed over from my office to the convention center, and I obtained an electronic file of the booth graphics from the graphics vendor. Documents in hand, I marched over to the GES

Exposition Services office in the exhibit hall and asked the reps if they could help me replicate a booth from these documents. The GES staffers told me that while their

replacement wouldn't likely be a

perfect match for the original, they could at least provide me with

a booth that would properly display the client's merchandise. I began by having copies of the exhibit renderings and blueprints faxed over from my office to the convention center, and I obtained an electronic file of the booth graphics from the graphics vendor. Documents in hand, I marched over to the GES

Exposition Services office in the exhibit hall and asked the reps if they could help me replicate a booth from these documents. The GES staffers told me that while their

replacement wouldn't likely be a

perfect match for the original, they could at least provide me with

a booth that would properly display the client's merchandise.

Next, I called the client and explained the situation. I also told him that while the GES replacement booth would cost more than the customized rental he'd contracted with my Midwest rival, I would pay the difference - all in an effort to win new business. He could let the fabricator fight it out with the freight company to recoup its losses on the booth, which would be on its way back to the Midwest once the truck was fixed. The client agreed.

Working all day and through the night, GES' installation crew and I finally finished the booth at 3 a.m. While the resulting exhibit wasn't an exact replica of the one that'd gone missing, the client was happy. And since I showed how responsible I was, he agreed to use us to build his future exhibits. I even got a nice note of thanks for all of my hard work.

- Nancy Lindell, trade show specialist, Idex Corp., Rohnert Park, CA

The Booth Bends

Two weeks before we headed to EXHIBITOR2008, my company, a manufacturer of modular architectural systems, introduced a new connector that would allow us to build exhibit walls at different angles. Wanting to highlight our new product at the show, I asked reps at the company headquarters in Germany to send a few of the connectors along with our booth, which they were shipping to the show. Two weeks before we headed to EXHIBITOR2008, my company, a manufacturer of modular architectural systems, introduced a new connector that would allow us to build exhibit walls at different angles. Wanting to highlight our new product at the show, I asked reps at the company headquarters in Germany to send a few of the connectors along with our booth, which they were shipping to the show.

But when we arrived at the show for setup and began unpacking our booth, it became obvious that the German reps had sent more than a few of the new connectors - which would create a 7.5 degree angle to the architecture. In fact, they'd sent too many and not enough of the parallel connectors that I needed.

Because setup was over a weekend, I couldn't get the correct parts delivered in time to build the booth by the show's opening. I needed to find a way to make lemonade out of the mismatched lemons I was dealt.

Quickly, I determined how many of each kind of

connector I had, and then tried to figure out what I could construct out of these angled connectors. I soon realized I could build the bulk of the exhibit properly if I revamped our archway entry. Instead of two support columns that came down in a pair of straight lines, I could make one column that came down as planned while the other column bent at a 7.5-degree angle halfway up. Quickly, I determined how many of each kind of

connector I had, and then tried to figure out what I could construct out of these angled connectors. I soon realized I could build the bulk of the exhibit properly if I revamped our archway entry. Instead of two support columns that came down in a pair of straight lines, I could make one column that came down as planned while the other column bent at a 7.5-degree angle halfway up.

Those columns were originally designed to support shelves that we were planning to use to display product literature on either side of the entryway. But as I drew it out in my head, I realized that if I built the 7.5-degree angle above the level of the shelves, the literature displays would not be affected by the change to the structure.

Not wanting to waste time, I explained my plan to the installation crew. Thankfully, they caught on quickly and built the booth along with its one bent column. Then, I held my breath to see if anyone would notice once the show opened.

A few hours into the show, I finally exhaled a long sigh of relief. Nobody but the I&D guys and I knew anything had gone amiss. And if anyone commented on the crooked column, I just pointed out the adaptability of our product, and they seemed to think it was all part of my original plan.

- Kerstin Mulfinger, architect,

Burkhardt Leitner Constructiv

Inc., Toronto

|

Nothing ruins your day more than losing a vital exhibit component to the shipping gods. But when that item is actually an entire booth - or worse, the booth you've promised to erect for a brand new client from which you hope to win future business - then your day is about as bad as it'll get.

Nothing ruins your day more than losing a vital exhibit component to the shipping gods. But when that item is actually an entire booth - or worse, the booth you've promised to erect for a brand new client from which you hope to win future business - then your day is about as bad as it'll get. I began by having copies of the exhibit renderings and blueprints faxed over from my office to the convention center, and I obtained an electronic file of the booth graphics from the graphics vendor. Documents in hand, I marched over to the GES

Exposition Services office in the exhibit hall and asked the reps if they could help me replicate a booth from these documents. The GES staffers told me that while their

replacement wouldn't likely be a

perfect match for the original, they could at least provide me with

a booth that would properly display the client's merchandise.

I began by having copies of the exhibit renderings and blueprints faxed over from my office to the convention center, and I obtained an electronic file of the booth graphics from the graphics vendor. Documents in hand, I marched over to the GES

Exposition Services office in the exhibit hall and asked the reps if they could help me replicate a booth from these documents. The GES staffers told me that while their

replacement wouldn't likely be a

perfect match for the original, they could at least provide me with

a booth that would properly display the client's merchandise.