very year, the $724 billion printing and paper industry spews a toxic ocean of more than 300 chemicals. In fact, the industry belches out so much carbon dioxide (CO2), methane, nitrous oxide, and other greenhouse emissions that the World Resources Institute ranks the industry slightly below coal mining in the sheer amount of those gasses disgorged.

Despite this, just 37 percent of the industry's companies report having a formal sustainability policy, according to research by the Print Industry Center at the Rochester Institute of Technology. But for more than 20 years, Heidelberger Druckmaschinen AG (aka Heidelberg), a maker of offset and precision printing presses, post-press equipment, plate setters, and printing-related software, resisted the environmental inertia to which many others succumbed. After adopting a commitment to Green practices in 1992, the Heidelberg, Germany-based firm was the first in the industry to receive

|

|

A pacesetter for sustainable practices within the printing industry, Heidelberger Druckmaschinen AG outdid itself with an eco-conscious exhibit at Drupa 2012.

|

international certification for environmental protection in 2001.

In the ensuing years, Heidelberg steadily built on the eco-friendly reputation it had painstakingly earned. For instance, it manufactured several types of printing presses that were more energy efficient than its rivals.

Along with those products, it made other presses that used no alcohol-based solvents in their cleaning cycles, thereby reducing the amount of volatile organic compounds released into the atmosphere.

Heidelberg didn't rest on those eco-conscious laurels, though. It kept expanding the scope of its efforts, from manufacturing energy-saving products to neutralizing those products' overall environmental effect. It even offset the environmental damage of all of its Speedmaster SX 52 Anicolor presses by contributing to a massive reforestation project in Togo.

You don't need to be Sherlock Holmes to see the pattern forming here. Heidelberg had positioned itself as a pacesetter for sustainable practices in the printing industry. But out of that very success came its next challenge: living up to its own reputation.

|

|

|

|

Efficient Routes

Heidelberg hired shippers who used computerized traffic-control systems that would plot the most efficient routes. |

|

Mass Transit

After proscribing individual or air transport to Dusseldorf, Heidelberg arranged bus transportation to and from Drupa for its show team.

|

|

Fuel Savings

Heidelberg used firms with electric-powered forklifts to move materials, rather than ones running on fossil fuels.

|

Climate Change

Between its eco-friendly products, industry leadership in Green practices, and public commitments, Heidelberg was the star student who ruined the curve for everyone else, except, perhaps, in one area: trade shows. There, the company was slower to bring its exhibiting program to the same verdant level of its other products.

It wasn't as if Heidelberg's exhibit program was secretly burying nuclear waste in Yellowstone National Park. At the 2008 Drupa, the quadrennial trade show that is also one of the world's largest print industry expos, the company offset the CO2 emissions of all the print products it produced on Environment Day, a day designated by the United Nations to raise awareness of ecological matters that occurred during the show's run. Two years later at the 2010 International Printing Machinery and

|

|

Approximately 65 percent of the 331 tons of materials used – such as steel beams, textiles, and carpets – had been recycled, or would be recycled after the show.

|

Allied Trades Exhibition (IPEX) in Birmingham, United Kingdom, it offset its 108,000-square-foot booth's estimated CO2 emissions of 703 tons by making a donation to NatureOffice's climate-protection project in the New Caledonian islands near Australia. "Our consistent progress on sustainability has been firmly established for more than 20 years," says Ulrich Boerger, vice president of marketing, trade shows and events for Heidelberg. "Our objective is to continuously improve in this field, and to include our customers and suppliers in this process as well."

That's where the danger for Heidelberg lay. Greening is a dicey proposition for even the most conscientious companies, one where there are more landmines than in the demilitarized zone between North and South Korea. Unless sustainable practices are fully integrated into every visible aspect of a company's business, it runs the risk of those efforts being interpreted as more of a stunt than an act of sincerity. Although Heidelberg's exhibit program was demonstrably becoming more ecologically sound, its stated goal was to "continuously improve," and that could create a credibility gap if its exhibits didn't appear to keep pace with the rest of the company. After all, when it comes to the environment, you're only as Green as your dirtiest part.

Suppliers and Demands

Heidelberg realized that Greening its exhibit meant taking a quantum leap forward in making its policies, products, materials, and suppliers all part of an intricate solution. Starting in March 2011, it rolled out a meticulous plan to create a booth for Drupa 2012 that would fulfill the company's increasingly expansive environmental agenda, and thereby strengthen the link between sustainable practices and the Heidelberg brand. The exhibit at Drupa 2012 would be completely carbon neutral (that is, Heidelberg would offset the amount of CO2 and other gasses emitted), consume less energy than the exhibit in 2008, and achieve all its marketing

|

|

Heidelberg reduced physical waste by 85 percent compared to 2008, and expended 0.035 megawatts of lighting, an astounding 29 times less than what it used in 2008.

|

goals as well. Though the company is mum on specific pre-show goals, it focused heavily on generating product orders at the quadrennial trade show.

For any other company trying to achieve this, it might be manifesting the kind of hubris that got Icarus a pair of melted wings and a crash landing. But if Heidelberg's strategy was successful, it could leave the company the print industry equivalent of Google, and everyone else a Bing in a distant and despairing second place. Therefore, Heidelberg went to extraordinary lengths to guarantee its Greening effort would do anything but flop. In fact, the process for planning the show resembled a small military operation, with 1,200 Heidelberg employees taking part at various stages.

The first step the company took was to vet potential exhibit builders for their own sustainable practices – or the lack thereof. Here, the company cribbed a page from Wal-Mart Stores Inc.'s environmental play-book. When the retail giant announced in 2005 several aggressive environmental goals – plans that included reducing its 8,900 stores' energy use by 30 percent – it decided to work only with suppliers who had Greened their practices, especially in packaging and transportation, as well. That created an environmentally friendly domino effect, where suppliers had to clean up their own act if they wanted to continue to do business with Wal-Mart. If Heidelberg executed the same play successfully, in the end everyone – Heidelberg, its suppliers, its customers, and the public at large – would win.

Boerger and the marketing department vetted a total of eight potential exhibit builders with the help of Pro Event Live-Communication GmbH, an event-production company based in Heidelberg, Germany. The company had crafted Eventums, an ingenious environmental-management system for trade shows and events. Eventums includes checklists on topics from venues, design, and logistics, to lighting technology, water usage, and furniture rental. Moreover, it came with a directory on sustainable procurement, as well as a guide offering information on Green materials.

The system also used a score card of nearly 30 items to determine the Heidelberg candidates' level of Green, including whether they had an internationally certified environmental-management system (known as ISO 14001, EMAS); an environmental officer; and regular assessments of their companies' CO2 emissions, along with a corresponding strategy to reduce them. The extensive checklist even included queries on whether the companies informed their clients about how they could reach their headquarters via public transportation.

carbon footprint

breakdown (in tons)

By choosing suppliers that met strict Green criteria and reducing its carbon footprint from start to finish, Heidelberg kept its emissions to about 4,341 tons.

Planning of the exhibit including business travel and various office work: 115.6

Transportation and accommodations for staff and invited guests during the exhibition: 2,575.4

Logistics and shipping of all major items to the show: 107.2

Exhibit operations (printing, paper usage, giveaways, miscellaneous materials): 517.3

Waste disposal (garbage sorting and removal during and after the show): 118.7

Suppliers (environmental impact of nearly 18 suppliers for items such as food, security, cleaning, and other services): 699.9

Five percent added to account for uncertainties in the calculation: 206.7

Total: 4,340.8 tons

Total: 4,340.8 tons

|

When the dust cleared, just three of the candidates met the company's stringent criteria. Of the trio, Heidelberg chose B+S Exhibitions GmbH of Dusseldorf, Germany, to build its booth. While not part of the official vetting, KMS Blackspace GmbH and Schmidhuber + Partner GbR, both of Munich, were asked to lend their design expertise to the exhibit.

The Show Behind the Show

Heidelberg had more than just the massive logistic and environmental challenges to tame. It also had to curb the effect of a budget for the show that was chopped by 50 percent.

Heidelberg and B+S addressed the problem by shrinking the booth's footprint by almost 20 percent. From roughly 108,000 square feet in 2008, the booth thinned down to a svelte 86,000 square

feet for 2012. Its weight – including materials for its construction and the products that would be displayed in it – dropped from 600,000 pounds in 2008 to 400,000 pounds. Normally, a contraction of that magnitude might result in a weakened presence, especially at the highly competitive Drupa with its nearly 2,000 exhibitors.

And to put it bluntly, a diminished presence at Drupa because of a second-rate, pedestrian booth would have put Heidelberg in an unenviable position. But as it turned out, Heidelberg quickly realized the smaller, lighter footprint would have a beneficial ripple effect: The downsized booth meant less CO2 would be emitted during the building, transportation, installation, and dismantling phases. For example, the smaller exhibit gave Heidelberg the impetus to ship 20 percent fewer products to the show. That would help Green the booth by having fewer items to transport, and fewer items on the show floor in turn meant less electricity would be consumed.

After dealing with the budget, Heidelberg initiated the next phase in its sustainability strategy. The company and B+S carefully analyzed the sources of CO2 emissions in several areas, including energy, shipping, waste-disposal management, transportation, and accommodations. Working together, they found a series of ways to reduce their impact on the environment. For example, to ship the materials to the show venue, Messe Dusseldorf, Heidelberg hired only transporters who used computerized traffic-control systems that would plot the most efficient routes. These companies were also required to have software that optimized their storage capacity, and use electric-powered forklifts rather than fossil-fuel-powered forklifts.

On top of these requirements, the shippers had to carry all materials in recyclable transportation boxes. They were also obligated to manage their own waste disposal at the show by separating materials into the appropriate categories (plastic, paper, etc.) and making sure they were either recycled or disposed of in the proper way. Additionally, Heidelberg assigned an employee to oversee its own waste disposal in the same manner.

The third area it focused on was lighting. At Drupa 2008, the company kept its incandescent and halogen lights burning 24 hours a day because the electrical surges involved in switching

the lights on and off resulted in 30 percent of them burning out. Still, it was an extravagant waste of energy. For Drupa 2012, Heidelberg replaced all of its lighting with LEDs, which use less energy and last longer. The company also crafted a lighting policy during the building phase: Within 15 minutes after work on the exhibit had shut down for the day, all light sources were to be switched off, except for the emergency and safety lights required by law.

Heidelberg even extended its Greening effort to staff travel and accommodations. When the 130 staffers departed for the trade show in May, they didn't hop into their own cars or jump on fuel-gulping airplanes. Instead, Heidelberg hired buses to chauffeur the fair team the 180 miles to Dusseldorf. Once there, employees, and even invited clients, were hosted only in hotels with public-transport

options nearby so staffers wouldn't have to resort to taxis to get to and from the show site.

|

|

To promote its annual Eco Printing Award recognizing printing companies for innovative sustainable practices, Heidelberg placed a large patch of grass on the curtain wall in its exhibit.

|

At first blush, it may seem like Heidelberg's preparations were much ado about nothing. How much of an impact, after all, could one company's exhibit have on the environment? But that misconception would quickly dissolve if you were to glimpse the sheer scale of Heidelberg's booth.

One month before Drupa opened its doors in May 2012, Heidelberg began constructing its booth at Messe Dusseldorf. Even pared down from 2008, it was nearly the size of a soccer field. The undertaking involved almost 200 service engineers, booth builders, electricians, and lighting and audio engineers, along with 2,004 tons of various materials that had to be transported to the show site. (The weight was equal to about 180 school buses.) The exhibit's physical impact on the trade show floor was the kind that could be measured with a seismograph. But whether its impact among attendees would be as great was a mystery that only the upcoming Drupa would solve.

The Carbon Neutral Zone

Green can sometimes seem synonymous with bland. It wouldn't be shocking, with all of Heidelberg's emphasis on ecological correctness, if the exhibit turned out as appealing to the eye as a bowl of sprouts with wheat germ sprinkled on top. So the company had ingeniously devised ways to use eco-friendly materials to attract thousands of the show's 390,000 attendees as irresistibly as a magnet draws iron filings.

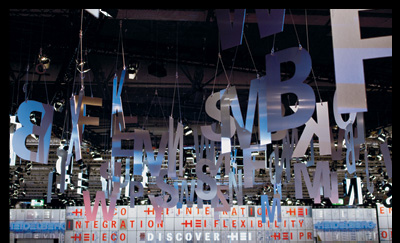

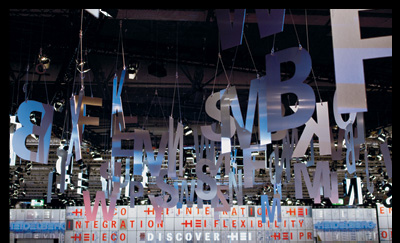

Surrounding part of the booth was a 21-foot-high, 1,200-foot-long chipboard curtain that looked like the "Wheel of Fortune" game board magnified enough for King Kong to play. Hung from ceiling trusses, the curtain was colored in red and white using water-based paints and lacquers. The structure comprised nearly 3,000 used aluminum printing plates, many of which had letters cut out of them, stencil-like, to spell out the company's buzzwords for the show, such as "Discover Hei," "Flexibility," and "Productivity." Even more cleverly, the plates – whose 27.6-by-39.4-inch size ensured attendees could see them virtually across the show floor – were used to denote the booth's various product areas, such as Commercial Print Solutions and Services.

LED panels were incorporated into some of the plates as well, running video loops about the company and its products. At the service center in the booth, dozens of aluminum letters were suspended by wire from an overhead truss. The recyclable letters formed a typographical sculpture that seemed to float in the air like delicate metal butterflies.

|

|

Instead of operating its equipment nonstop throughout the show, Heidelberg demonstrated its 12 presses and 11 post-press machines only at specific, posted times.

|

Attendees jammed inside the booth, where there was more used material than a Goodwill store. Approximately 65 percent of the 331 tons of materials used – such as steel beams, textiles, and carpets – had been recycled, or would be recycled after the show. The 292 chairs, stools, and various other pieces of furniture had all been rented, and would therefore live again in other venues. In 2008, the company had burned energy like Colorado wildfires, with nonstop demonstrations of all its printing machines for up to six hours at a time. In 2012, it substituted video and other multimedia demonstrations to show off its wares, with short, real-life demos of the 12 presses and 11 post-press machines only at specific times that were posted in the booth. Instead of using graphic foils as it had at the previous Drupa, Heidelberg turned to projections to splash the walls with marketing messages. The number of giveaways was sharply reduced, while the embedded LED screens enabled the company to cut back dramatically on paper literature.

The result for Drupa attendees was a hypnotic hybrid of a post-modern warehouse and a new-wave art installation that wouldn't have been out of place in New York's Museum of Modern Art. The results for Heidelberg were a masterpiece of a different kind. After close to 15 months of planning and building the exhibit, Heidelberg offset the environmental impacts of the nearly 4,341 tons of CO2 that entered the air. It reduced physical waste by 85 percent compared to 2008, and expended 0.035 megawatts of lighting, an astounding 29 times less than what it used in 2008. By any reckoning, Heidelberg's booth was an impressive accomplishment of style and substance. So impressive, in fact, that the exhibit received a prestigious Red Dot Design Award for communication design from an international panel of judges.

If you're inclined to say, "Show me the green instead of the Green," here's something to ponder. Although Heidelberg maintained its air of corporate omerta about pre-show goals, it announced the company accumulated almost 2,000 orders at Drupa, including 550 for sheet-fed offset presses alone. Furthermore, by Greening everything from the construction materials to light bulbs to the suppliers' forklifts, Heidelberg cut its booth costs by $300,000 when compared to the previous Drupa. Yet even those figures pale next to overall orders, which swelled to $1.2 billion, compared to $902 million the first quarter of the previous year, making it plain to Heidelberg that its exhibit at Drupa was at least partly responsible for the nearly 33-percent surge.

By building on its past efforts, Heidelberg had woven eco-friendly practices so deeply into the exhibit that it was more like DNA than design. Indeed, the company will use the same approach for its booths at future trade shows, such as Ecoprint Europe and InPrint. Those practices resulted in a money-saving, eye-catching exhibit that also spurred sales and generated public recognition with various awards. To anyone, that accomplishment wouldn't just be Green, but golden.

very year, the $724 billion printing and paper industry spews a toxic ocean of more than 300 chemicals. In fact, the industry belches out so much carbon dioxide (CO2), methane, nitrous oxide, and other greenhouse emissions that the World Resources Institute ranks the industry slightly below coal mining in the sheer amount of those gasses disgorged.

very year, the $724 billion printing and paper industry spews a toxic ocean of more than 300 chemicals. In fact, the industry belches out so much carbon dioxide (CO2), methane, nitrous oxide, and other greenhouse emissions that the World Resources Institute ranks the industry slightly below coal mining in the sheer amount of those gasses disgorged.