cost cutting |

|

ow more than ever, Americans are entrenched in a do-or-die battle of the bulge. Enlisting everything from gastric-bypass surgery to P90X, we're trying to shrink, tone, tighten, and tuck our way to an "ideal" weight and size that's more air-brushed illusion than healthy reality. ow more than ever, Americans are entrenched in a do-or-die battle of the bulge. Enlisting everything from gastric-bypass surgery to P90X, we're trying to shrink, tone, tighten, and tuck our way to an "ideal" weight and size that's more air-brushed illusion than healthy reality.

But pudgy Americans aren't the only ones trying to trim down these days. Especially given today's anorexic exhibit-marketing budgets, exhibitors are also looking for ways to drop a few pounds - or maybe even several tons - from their programs. With soaring shipping fees and often-exorbitant drayage costs, eliminating even a little weight from your exhibit program can put hundreds or thousands of dollars back in your program's pocket.

What's more, in today's eco-conscious society, shipping tons of products and exhibitry to a show is akin to clubbing baby seals in front of your customers.

For companies selling services or lightweight products, exhibit managers can often lighten their load by trading their exhibits' rigid forms and hefty steel structures for lightweight aluminum supports and fabric elements. Should they so choose, these fortunate folks can drop the pounds faster than Mel Gibson trashed his career.

But what if you're saddled with heavyweight products? Attendees go to trade shows to see your wares - not to ogle your exhibitry. And no matter how savvy your staffers and how stunning your booth, at some point, attendees are going to ask, "When can I check out the goods?"

EXHIBITOR found three companies that used everything from simple handmade models to various forms of high-tech wizardry to swap their hefty products for inventive lightweight replacements. What's more, they slightly shifted, and improved, their overall exhibit-marketing strategies - ultimately cutting their product-related weight figures by up to 92 percent.

|

At Fujitsu Network Communications Inc., a division of Fujitsu Ltd., products have always formed the core of the company's exhibit-marketing strategy, due at in part to its Japanese heritage. For while the division has offices in Sunnyvale, CA, its parent company, Fujitsu Ltd., is based in Japan. "And Japanese-based firms take enormous pride in their products and the engineering that went into them," says Michael Rapp, senior manager of e-media, creative, and exhibits for Fujitsu's communications-network solutions division. "So up until about 2007, at trade shows like Supercomm, the Cellular Telecommunications and Internet Association (CTIA) show, and the Society of Cable Telecommunications Engineers (SCTE) Cable-Tec Expo, our exhibiting strategy always revolved around our main products, which were prominently displayed in our booth." Problem was, those main products had significant weight issues and some rather odd internal fees. At Fujitsu Network Communications Inc., a division of Fujitsu Ltd., products have always formed the core of the company's exhibit-marketing strategy, due at in part to its Japanese heritage. For while the division has offices in Sunnyvale, CA, its parent company, Fujitsu Ltd., is based in Japan. "And Japanese-based firms take enormous pride in their products and the engineering that went into them," says Michael Rapp, senior manager of e-media, creative, and exhibits for Fujitsu's communications-network solutions division. "So up until about 2007, at trade shows like Supercomm, the Cellular Telecommunications and Internet Association (CTIA) show, and the Society of Cable Telecommunications Engineers (SCTE) Cable-Tec Expo, our exhibiting strategy always revolved around our main products, which were prominently displayed in our booth." Problem was, those main products had significant weight issues and some rather odd internal fees.

"My division makes these high-capacity optical-transmission components," Rapp says. "The components assist in enabling almost every phone call you make - be it via land line or cell phone. These components, which are stacked vertically to form what we call a 'rack,' can weigh upwards of 700 pounds per rack. And when you consider that we used to bring about six racks to most industry shows, we're talking about 4,500 pounds in products and packaging alone." "My division makes these high-capacity optical-transmission components," Rapp says. "The components assist in enabling almost every phone call you make - be it via land line or cell phone. These components, which are stacked vertically to form what we call a 'rack,' can weigh upwards of 700 pounds per rack. And when you consider that we used to bring about six racks to most industry shows, we're talking about 4,500 pounds in products and packaging alone."

If you do the math using the average drayage rate for advanced shipments to the exhibit hall (which is $74.90 according to Tradeshow Week's Survey of U.S. and Canadian Labor Rates), that's more than $6,700 per show just to move the product from the venue's loading docks to Fujitsu's booth space.

In addition, the marketing department incurred significant costs merely to obtain the products from Fujitsu's inventory for display in the booth. "We have to rent products from our own inventory," Rapp says. "When we display products, which take considerable time and materials to build, they're not in our inventory that's available for sale. So we pay another department in our company one-thirty-sixth of the value of the products per month to pull them out of inventory. This costs the marketing department upwards of $1,800 a month to do so. And if we keep the products for, say, 10 months during our busiest part of the year, that's $10,800 a year in rental fees."

Despite this seemingly budget-busting scenario, for approximately the last 20 years, Fujitsu felt the benefits of bringing these products to shows outweighed the associated costs to do so. During this time, the products in and of themselves were unique, and served as key differentiators. However, the changing competitive landscape and the increasing sophistication of customers' needs today forced Fujitsu to rethink its marketing strategy and identify a new differentiator. Despite this seemingly budget-busting scenario, for approximately the last 20 years, Fujitsu felt the benefits of bringing these products to shows outweighed the associated costs to do so. During this time, the products in and of themselves were unique, and served as key differentiators. However, the changing competitive landscape and the increasing sophistication of customers' needs today forced Fujitsu to rethink its marketing strategy and identify a new differentiator.

Going forward, then, Fujitsu decided that instead of highlighting a handful of products in its marketing efforts, it would rebrand itself as a full-solutions provider, one that wouldn't focus on individual products but rather a broad range of products, services, and software that together offered an end-to-end solution for customers. This change in strategy didn't actually swing the spotlight off of Fujitsu's products in the booth. Instead, it widened that beam to include the company's portfolio of solutions - not just a few pieces of star equipment.

In addition, in late 2007 Rapp - always looking to streamline his program and make it even more effective

- started searching for ways to cut costs. Thus, he began his quest for some way to display the breadth and depth of the company's products, all within the 50-by-50-foot booth used at most shows. He needed a way to both lighten his load and somehow communicate Fujitsu's vast offerings.

Side-by-Side Test Drive

Rapp found his solution via a company called Kaon Interactive Inc. The Maynard, MA, firm provides interactive 3-D sales and marketing solutions, often on a hardware appliance it calls the v-OSK, i.e., a virtual-enabled kiosk.

"Kaon could create a virtual solutions catalog, allowing us to show products, applications, and technologies on a single v-OSK within our booth - no matter what size footprint we used," Rapp says. "But instead of simply viewing product images and specs, attendees could interact with the v-OSK  touchscreen to manipulate the image of the product, look inside it, enlarge it, rotate it 360 degrees, etc. Plus, with the touch of a finger, they could access a menu and pull out various components from the equipment, zoom into them, and access their specs. They could even measure the size of the items and download whatever information they wanted directly from the v-OSK onto USB drives. They could access much more information right on the spot than they ever could by looking at the real product." touchscreen to manipulate the image of the product, look inside it, enlarge it, rotate it 360 degrees, etc. Plus, with the touch of a finger, they could access a menu and pull out various components from the equipment, zoom into them, and access their specs. They could even measure the size of the items and download whatever information they wanted directly from the v-OSK onto USB drives. They could access much more information right on the spot than they ever could by looking at the real product."

But when product has ruled the corporate culture for decades, it's not easy to

dethrone the king. So to convince stakeholders that virtual products were just as good as the real thing, Rapp set up a test scenario in his exhibit at NXTcomm.

"We had Kaon virtualize several of our products and load this information to a couple of their v-OSKs," Rapp says. "In the booth, we set up the two v-OSKs within a few feet of the actual products to create

a side-by-side comparison. Then we monitored the manner in which attendees chose to view the products

- electronically or in the flesh, so to speak. And sure enough, our observations showed that the virtual models were far more popular with attendees

than the real products."

Upon achieving similar results in additional side-by-side tests, Rapp received management's permission to leave almost all of the equipment at home and take a majority

of the in-booth product presentations virtual.

After roughly a year spent testing the strategy and redesigning the booth to fit it, Fujitsu launched its v-OSK-enabled booth starting in 2009. The redesigned booth included four roughly 26-by-8.5-by-41-inch v-OSKs loaded with virtual representations of the company's complete product portfolio - or as Rapp prefers to call it, a "complete solutions portfolio."

Previously, at least 50 percent of the exhibit footprint was devoted to products, but with the new design, the v-OSKs only took up about 25 percent of the booth. The extra space, then, was used to create a more customer-centric - as opposed to product-centric - experience. "The extra space allowed us to create a destination, with lounges, catering, seating, etc., as opposed to a 'walk in, kick the tires, and move on' sort of experience," Rapp says.

Real Results

While Rapp used to ship roughly 4,500 pounds of product (including packaging) to each show, the four v-OSKs he uses at his largest shows only account for 720 pounds max. "By using the v-OSKs, we cut our 2009 shipping and drayage weight by 84 percent compared to 2008 figures." Plus, the $10,800 typically used to rent the products from Fujitsu's internal inventory can now be redirected to other exhibit-marketing tactics.

In addition, the quality of leads gathered in the booth has increased significantly. "Rather than merely talking about whatever equipment is on display in the booth, our salespeople can watch as attendees progress through our entire solutions portfolio on the v-OSKs and note which areas hold their attention the longest," Rapp says. "That way, they can better ascertain attendees' interests and note them when inputting lead information. Following the show, we can send prospects information specifically geared to their interests, and during follow-up phone calls, salespeople can use this information to better

focus their conversations and quickly move toward a sale."

What's more, the dividends extend off the trade show floor. Fujitsu posted the 3-D product virtualizations to its website and created downloadable PDFs for customers and prospects to reference. Within the first quarter after the catalog went live, Fujitsu collected 144 new leads, and ultimately 11 of those leads resulted in $750,000 in sales revenue. What's more, the dividends extend off the trade show floor. Fujitsu posted the 3-D product virtualizations to its website and created downloadable PDFs for customers and prospects to reference. Within the first quarter after the catalog went live, Fujitsu collected 144 new leads, and ultimately 11 of those leads resulted in $750,000 in sales revenue.

Plus, Rapp has since been able to reallocate the savings - including shipping and drayage fees as well as inventory-rental costs - to other events including road shows, customer-only events, and smaller, more targeted marketing meetings where behemoth products wouldn't dare to venture. In addition, the virtual solutions portfolio has been loaded onto four Kaon Presenter modules, essentially transferring the info from the v-OSKs to a large-format display system. Doing so means that the catalog is far more mobile and can be used for media briefings, analyst events, internal meetings, etc.

For Fujitsu, replacing a few real products with countless virtual products and solutions not only saved money; it allowed the company to add a new revenue stream and several additional marketing tactics to its arsenal.

|

Prior to 2008, the exhibit-marketing team at Generac Power Systems Inc. had more than a weight problem; attendee-engagement issues were also dragging down their exhibit's effectiveness. Based in Waukesha, WI, the generator manufacturer typically displayed its industrial-size wares at roughly five shows per year, including behemoths such as the American Society for Healthcare Engineering show (ASHE) and the Cellular Telecommunications and Internet Association (CTIA) show. Within its 20-by-30-foot and 20-by-20-foot booths, Generac typically displayed up to five generators, which range in size from approximately 2.5-by-3-by-5 feet to 3-by-5-by-9 feet. Prior to 2008, the exhibit-marketing team at Generac Power Systems Inc. had more than a weight problem; attendee-engagement issues were also dragging down their exhibit's effectiveness. Based in Waukesha, WI, the generator manufacturer typically displayed its industrial-size wares at roughly five shows per year, including behemoths such as the American Society for Healthcare Engineering show (ASHE) and the Cellular Telecommunications and Internet Association (CTIA) show. Within its 20-by-30-foot and 20-by-20-foot booths, Generac typically displayed up to five generators, which range in size from approximately 2.5-by-3-by-5 feet to 3-by-5-by-9 feet.

The generators' physical dimensions, however, weren't nearly as cumbersome as their weight, says Kent Jones, senior vice president and client-results strategist for 3D Exhibits Inc., an Elk Grove Village, IL-based exhibit house. "Weighing upwards of 5,000 pounds each, the larger generators are purchased by facility managers and engineers from a wide variety of industries, including everything from hospitals and data centers to telecommunications firms and manufacturing plants," Jones says. "Even the smaller models, sold to residential, commercial, and industrial customers, tip the scales at 1,500 pounds."

In fact, Jones estimates that Generac was paying more than $30,000 per year for shipping and drayage costs. So when Generac's management started to tighten the belt on the marketing budget in early 2008, the marketing team began looking for ways to trim the fat. Surely there had to be some way to cut down on the amount of product going to shows without negatively affecting the attendee experience. In fact, Jones estimates that Generac was paying more than $30,000 per year for shipping and drayage costs. So when Generac's management started to tighten the belt on the marketing budget in early 2008, the marketing team began looking for ways to trim the fat. Surely there had to be some way to cut down on the amount of product going to shows without negatively affecting the attendee experience.

However, product weight wasn't Generac's only issue. The marketing team also felt that given the product-centric booth, the attendee/staffer interaction was limited in scope. For while staffers were well versed in Generac's products and were effective in communicating with attendees, they didn't have a visual aid that would allow them to physically show prospects how the product integrates with their environments.

For example, staffers

talked about general product specs - not about how a specific health-care facility would need to control power with the transfer switches to meet government specs, or where the generator's

fuel source would be placed.

So to replace Generac's product-centric strategy, 3D Exhibits suggested that a more customer-interactive solution, including a visual representation of customers' environments, would generate more booth traffic, create a more dynamic in-booth experience, and ultimately move people further along in the sales process. Thus, as Generac planned the rest of its 2008 shows and its 2009 calendar, it turned to 3D Exhibits for some help. It hoped a change in its product-display strategy might not only help cut shipping and drayage costs, but also help booth staffers to hold more personal, attendee-centered conversations.

The Low-Tech Solution

"Generac was open for change and eager to cut costs. So rather than going the high-tech route with more exhibit structure, we decided to try something a little bit different - something that we felt would be relatively inexpensive and that would still stand out on the show floor," Jones says. "We took the quiet route with an incredibly low-tech solution: 3-D models."

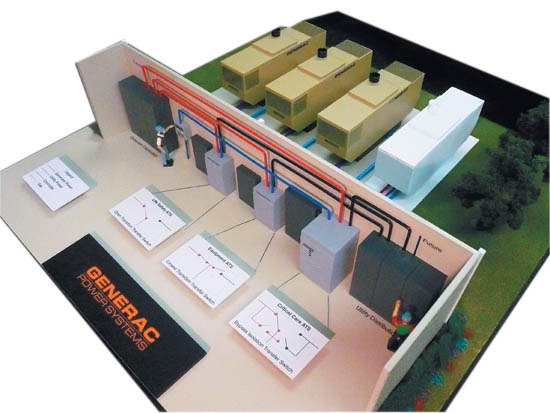

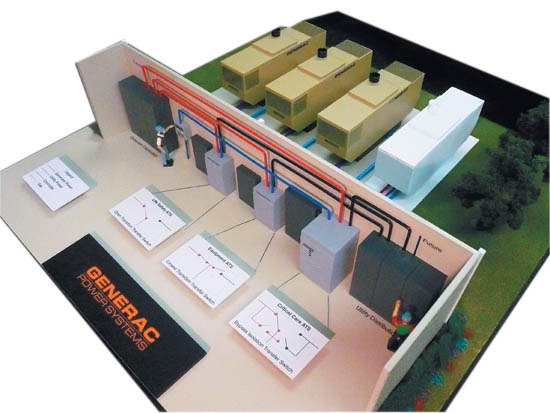

The proposed 3-foot-square architectural models would represent various scenarios in which Generac's generators might reside, such as a communication station, cell-phone tower, hospital, etc. For example, the health-care model would show a generator-equipped hospital and power-control room minus the building's roof. Used at health-facility management shows, the model would allow staffers to speak directly about how Generac's equipment operated within this specific setting and to tailor conversations to the health-care management audience. Staffers could use the model to illustrate where generators could be placed, where and how the fuel centers worked, how transfer switches would route the power, how cables would be run, etc. These kinds of industry-specific conversations weren't really possible - or at least not highly effective - when staffers and attendees focused only on a giant product staring them in the face. Plus, 3D Exhibits found a way to make the model production extremely cost effective. The proposed 3-foot-square architectural models would represent various scenarios in which Generac's generators might reside, such as a communication station, cell-phone tower, hospital, etc. For example, the health-care model would show a generator-equipped hospital and power-control room minus the building's roof. Used at health-facility management shows, the model would allow staffers to speak directly about how Generac's equipment operated within this specific setting and to tailor conversations to the health-care management audience. Staffers could use the model to illustrate where generators could be placed, where and how the fuel centers worked, how transfer switches would route the power, how cables would be run, etc. These kinds of industry-specific conversations weren't really possible - or at least not highly effective - when staffers and attendees focused only on a giant product staring them in the face. Plus, 3D Exhibits found a way to make the model production extremely cost effective.

"Generac actually hired my then 17-year-old son and me to build four different models," Jones says. "After pitching the do-it-yourself solution to their marketing team, they weren't immediately sold on the idea. But given the anticipated savings in shipping and drayage, and the fact that using my son and I would cost roughly 75 percent less than a professional architectural-model builder, they definitely wanted to try it out. So we started building the first model - the hospital environment - in our basement."

Once the model was finished, the father-and-son team stopped production for a quick test run. For the ASHE 2008 show in Washington, DC, Generac left its generators at home and in their place, and positioned the hospital model atop an aisle-side table in its 20-by-20-foot booth. After carefully training the exhibit staff on how to engage attendees with the new model, Generac's marketing team stood back and observed.

Small Solution, Big Results

As 3D Exhibits expected, attendees swarmed the model like tweens to a Justin Bieber sighting. "Attendees were attracted to the model because as boys, many of them no doubt made models of their own," Jones says. So the nostalgic lure, along with the fact that the model was open and touchable, drew in attendees for a closer look. "Plus, I think attendees appreciated the fact that this wasn't another high-tech presentation," Jones says. "It was something unique and low-tech on the exhibit floor, and something that required further investigation." In fact, booth traffic at ASHE 2008 increased by an estimated 30 percent compared to previous years.

Based on the increased exhibit traffic and the improved engagement between booth staff and attendees, Generac asked Jones and his son to quickly crank out three more models for specific target-market applications for the remaining 2008 shows and the 2009 calendar. Featuring intricate details including everything from faux grass and fencing to miniature engineers and transfer-switch diagrams, the models packed easily into hard-sided carrying cases with foam-molded interiors for easy transport.

While Generac still brings a generator to major trade shows and it has retained the same size booth spaces as in previous years, compared to its 2007 booth, it now leaves approximately 80 to 90 percent of its bulky products at home. Positioned aisle side within Generac's exhibits, the architectural models continue to draw a relatively larger crowd than the products alone - and at a much smaller price. Jones estimates that for the roughly five industrial-sector shows at which Generac exhibited in 2009 and 2010, it cut more than $30,000 in annual shipping and drayage costs compared to 2007 figures. While Generac still brings a generator to major trade shows and it has retained the same size booth spaces as in previous years, compared to its 2007 booth, it now leaves approximately 80 to 90 percent of its bulky products at home. Positioned aisle side within Generac's exhibits, the architectural models continue to draw a relatively larger crowd than the products alone - and at a much smaller price. Jones estimates that for the roughly five industrial-sector shows at which Generac exhibited in 2009 and 2010, it cut more than $30,000 in annual shipping and drayage costs compared to 2007 figures.

Furthermore, the portability of the models means that Generac can use them at unrelated corporate events and small venues, which would have previously been off limits given the products' size and related shipping costs.

With a low-tech, no-nonsense approach to its weight issues, Generac's pint-size product solution cut costs and cranked up exhibit effectiveness to boot.

|

Ever wonder how oil and gas companies actually locate underground or underwater fuel deposits? They enlist the products and services of companies such as Ion Geophysical Corp. to help them capture seismic images of the Earth's subsurface and predict the location of subsurface energy sources. The Houston-based seismic-solutions company and its related partners offer everything from relatively small, digital seismic sensors to 13,000-pound vibrators that literally shake the earth to generate seismic readings. Ever wonder how oil and gas companies actually locate underground or underwater fuel deposits? They enlist the products and services of companies such as Ion Geophysical Corp. to help them capture seismic images of the Earth's subsurface and predict the location of subsurface energy sources. The Houston-based seismic-solutions company and its related partners offer everything from relatively small, digital seismic sensors to 13,000-pound vibrators that literally shake the earth to generate seismic readings.

As one might imagine,

Ion's marketing team doesn't have much trouble toting its tiny electronic equipment to trade shows. But not only does its 6.5-ton vibrating equipment shake the ground; shipping that equipment to shows practically breaks the bank. Nevertheless, prior to 2009, at key shows such as the Society of Exploration Geophysicists (SEG), which draws thousands of attendees from across the globe, Ion often packed up at least one of its monster machines for the show - reasoning that attendees wanted to see and touch the massive equipment for themselves.

Nearing the end of 2007 and into the early part of 2008, however, Ion decided to bring its exhibit strategy more in line with its image as a technology leader - and to cut a few costs in the process. "We tend to think of ourselves as a cutting-edge technology company, and we always want to stay ahead of the pack in terms of using new technology both in our products and in our exhibits," says Christine Feimer, Ion's director of digital communications. So instead of bringing its largest equipment to shows, Ion created what it calls a Virtual Ion Systems Toolkit.

"We hired a Houston firm to create a multimedia piece using 3-D models of our equipment and simulated energy-acquisition sites illustrating where our equipment would be placed," Feimer says. "For SEG 2008, we left the largest equipment at home, and displayed the Systems Toolkit on one monitor within our 50-by-60-foot booth." "We hired a Houston firm to create a multimedia piece using 3-D models of our equipment and simulated energy-acquisition sites illustrating where our equipment would be placed," Feimer says. "For SEG 2008, we left the largest equipment at home, and displayed the Systems Toolkit on one monitor within our 50-by-60-foot booth."

The Systems Toolkit offered basic product information and the ability to examine models of many of Ion's products, and it helped cut shipping and drayage costs considerably. However, the Systems Toolkit wasn't off the charts in terms of technological innovation, and Ion wanted something with a little more "oomph" to set it apart as a technology leader.

So in 2008, the marketing team began looking for a product-presentation technique with punch for SEG 2009 in Houston. "Meanwhile, the economy took a toll on travel budgets, and we were learning from our customers that companies planned to send fewer people to SEG than they had in years past," Feimer says. "So in 2009, we were looking for a low-cost, high-impact way to promote our products and services, but we were also looking for a way to reach out to the people who could no longer attend the live event."

Show Within a Booth

Rather than limit themselves to traditional exhibit-marketing technology, Feimer and her team extended their search to include tactics typically employed by entire trade shows, as opposed to individual exhibitors. When Ion happened upon ON24 Inc., a webcasting and virtual-events provider based in San Francisco, it not only found a new way to promote its products and services at the show; it also found a way to extend its show presence  to nonattending customers and prospects during and after the show. With the help of ON24, Ion created its own virtual trade show - solely featuring its products and services - in conjunction with its SEG 2009 presence. to nonattending customers and prospects during and after the show. With the help of ON24, Ion created its own virtual trade show - solely featuring its products and services - in conjunction with its SEG 2009 presence.

Starting at SEG 2009 and going forward into Ion's 2010 show calendar, attendees could peruse the virtual show's five areas at their leisure on two 19-inch monitors in Ion's booth, and nonattending customers and prospects could view it on their own computers.

"When you opened the virtual-show web link, a video popped up in which woman in an Ion-branded shirt welcomed visitors and explained the various areas of the show they could explore, including the Land Product Lab, Technical Hall, VIP Forum, Exhibit Hall, and Ion Party," Feimer says.

In the Land Product Lab, site visitors could sign up to participate in a collaborative product-development lab, where they could interact one on one with industry peers and Ion's research-and-development team. In the Technical Hall, visitors watched narrated presentations (think PowerPoint-style slides with audio commentary) about everything from case studies featuring Ion's products to overviews of the company's technology.

The virtual Exhibit Hall offered five different Ion booths. The Ion Equipment Booth, the Virtual Processing

Center Booth, the Basin-SPANS Data Room, and the Ion Recruiting Center all offered customers, prospects, and job applicants myriad info including everything from product data sheets and videos to job postings and the Ion Systems Toolkit.

Front and center in the exhibit hall, however, the Ion Booth was a rendered version of Ion's real 40-by-40-foot booth at SEG 2009. The virtual version provided information on land systems, marine systems, and data processing, and offered attendees the chance to view videos, presentations, brochures, and more.

Hefty Results Hefty Results

At SEG, Ion placed crowd gatherers at the edge of its space to lure people in to experience the virtual show (which was housed on two monitors positioned near the front of the booth). The crowd gatherers further tempted attendees with a digital-camcorder drawing. "Anyone who interacted with the virtual show and input their data into the kiosk's welcome screen was entered into a drawing to win one of two Webby digital cameras," Feimer says.

Within the booth, Ion offered kiosks with on-demand product presentations as well as some small equipment. While monitors along the exhibit's back wall and various graphics throughout provided additional info about Ion's offerings, the virtual trade show housed most of the product information.

After SEG 2009, Ion launched an online campaign announcing the virtual show to customers and prospects who might have missed it at the show. Ion kept its virtual trade show live for almost a year after the 2009 show. During that time, Ion estimates that approximately 1,300 customers and prospects visited the virtual show, where they were exposed to a trade-show-like experience - and Ion's products and services - without spending a dime.

Perhaps most importantly, however, Ion cut costs while establishing itself as a cutting-edge technology leader. Compared to its 2007 SEG booth, Ion saved upwards of $15,000 in shipping and floor space by leaving its large equipment at home. Plus, the virtual show has garnered significant media attention as well, including an article in USA Today's Travel section and a mention on BBC radio.

Cost savings, additional exposure, and an extension that brought Ion's message to clients and prospects that weren't in attendance? It sounds like Ion's lightweight strategy helped the company strike oil - both virtually and literally. E

|

|

|

ow more than ever, Americans are entrenched in a do-or-die battle of the bulge. Enlisting everything from gastric-bypass surgery to P90X, we're trying to shrink, tone, tighten, and tuck our way to an "ideal" weight and size that's more air-brushed illusion than healthy reality.

ow more than ever, Americans are entrenched in a do-or-die battle of the bulge. Enlisting everything from gastric-bypass surgery to P90X, we're trying to shrink, tone, tighten, and tuck our way to an "ideal" weight and size that's more air-brushed illusion than healthy reality.  At Fujitsu Network Communications Inc., a division of Fujitsu Ltd., products have always formed the core of the company's exhibit-marketing strategy, due at in part to its Japanese heritage. For while the division has offices in Sunnyvale, CA, its parent company, Fujitsu Ltd., is based in Japan. "And Japanese-based firms take enormous pride in their products and the engineering that went into them," says Michael Rapp, senior manager of e-media, creative, and exhibits for Fujitsu's communications-network solutions division. "So up until about 2007, at trade shows like Supercomm, the Cellular Telecommunications and Internet Association (CTIA) show, and the Society of Cable Telecommunications Engineers (SCTE) Cable-Tec Expo, our exhibiting strategy always revolved around our main products, which were prominently displayed in our booth." Problem was, those main products had significant weight issues and some rather odd internal fees.

At Fujitsu Network Communications Inc., a division of Fujitsu Ltd., products have always formed the core of the company's exhibit-marketing strategy, due at in part to its Japanese heritage. For while the division has offices in Sunnyvale, CA, its parent company, Fujitsu Ltd., is based in Japan. "And Japanese-based firms take enormous pride in their products and the engineering that went into them," says Michael Rapp, senior manager of e-media, creative, and exhibits for Fujitsu's communications-network solutions division. "So up until about 2007, at trade shows like Supercomm, the Cellular Telecommunications and Internet Association (CTIA) show, and the Society of Cable Telecommunications Engineers (SCTE) Cable-Tec Expo, our exhibiting strategy always revolved around our main products, which were prominently displayed in our booth." Problem was, those main products had significant weight issues and some rather odd internal fees.

The proposed 3-foot-square architectural models would represent various scenarios in which Generac's generators might reside, such as a communication station, cell-phone tower, hospital, etc. For example, the health-care model would show a generator-equipped hospital and power-control room minus the building's roof. Used at health-facility management shows, the model would allow staffers to speak directly about how Generac's equipment operated within this specific setting and to tailor conversations to the health-care management audience. Staffers could use the model to illustrate where generators could be placed, where and how the fuel centers worked, how transfer switches would route the power, how cables would be run, etc. These kinds of industry-specific conversations weren't really possible - or at least not highly effective - when staffers and attendees focused only on a giant product staring them in the face. Plus, 3D Exhibits found a way to make the model production extremely cost effective.

The proposed 3-foot-square architectural models would represent various scenarios in which Generac's generators might reside, such as a communication station, cell-phone tower, hospital, etc. For example, the health-care model would show a generator-equipped hospital and power-control room minus the building's roof. Used at health-facility management shows, the model would allow staffers to speak directly about how Generac's equipment operated within this specific setting and to tailor conversations to the health-care management audience. Staffers could use the model to illustrate where generators could be placed, where and how the fuel centers worked, how transfer switches would route the power, how cables would be run, etc. These kinds of industry-specific conversations weren't really possible - or at least not highly effective - when staffers and attendees focused only on a giant product staring them in the face. Plus, 3D Exhibits found a way to make the model production extremely cost effective.