exhibit design |

|

f necessity is the mother of invention, then it is also father of imaginative exhibit design. For when the need to create an exhibit far outweighs your budget to do so, you have no choice but to throw off the shackles of cherished practices, open your mind to previously unthinkable alternatives, and belly flop yourself into the unexplored waters of invention. f necessity is the mother of invention, then it is also father of imaginative exhibit design. For when the need to create an exhibit far outweighs your budget to do so, you have no choice but to throw off the shackles of cherished practices, open your mind to previously unthinkable alternatives, and belly flop yourself into the unexplored waters of invention.

The following three exhibitors didn't just throw off their shackles, they almost completely disrobed of convention. Facing seemingly insurmountable challenges such as a nonexistent exhibit budget - that's right, zip, zero, nada, zilch - they didn't just downsize the status quo, they demolished it.

In place of traditional exhibitry, they used donated or recycled materials, including everything from highway guardrails and shipping pallets to borrowed lamps and naked mannequins. And rather than shopping exhibit houses for functional pieces, they shopped their partners' warehouses, the California Highway Department's storage yard, and even their own shipping departments.

Comprising a hodgepodge of materials cohesively connected by exceptional design, the resulting exhibits aren't just cheap, they're innovative attention getters that stand out in the crowd. And what's more, their materials were not only recycled, found, or donated, many of them have since been reused for other nonexhibiting purposes.

So what lessons do these chic but cheap exhibits offer? While their unusual eye candy and back stories are a pretty interesting read, they also prove that innovative doesn't equal expensive - as one exhibitor cut his exhibit costs by 80 percent, and the other two built new exhibits for $7,000 and $0, respectively.

Plus, since two of the exhibit designers had never designed a booth before and the third is a marketing expert rather than a designer, they suggest that you don't necessarily need design degrees or experience to produce innovative exhibitry. So even if necessity doesn't force you to reengineer your company's booth, you might want to consider the inexpensive art of invention to help create a memorable, unconventional exhibit for your next show.

|

|

or 62-year-old custom cabinet manufacturer Crystal Cabinet Works Inc., exhibit design and construction is almost a second calling. In fact, the Princeton, MN, firm has been designing and building its booths for roughly 15 years, for shows such as the Kitchen/Bath Industry Show & Conference and NeoCon. or 62-year-old custom cabinet manufacturer Crystal Cabinet Works Inc., exhibit design and construction is almost a second calling. In fact, the Princeton, MN, firm has been designing and building its booths for roughly 15 years, for shows such as the Kitchen/Bath Industry Show & Conference and NeoCon.

Traditionally, the firm builds various freestanding metal or wood walls, covers them with sheetrock and wallpaper, and positions them to create a series of small room-like enclosures throughout its exhibit. It then attaches its various cabinet lines to the walls, adds a touch of decoration here and there to complete each vignette, and voila, instant product displays. Traditionally, the firm builds various freestanding metal or wood walls, covers them with sheetrock and wallpaper, and positions them to create a series of small room-like enclosures throughout its exhibit. It then attaches its various cabinet lines to the walls, adds a touch of decoration here and there to complete each vignette, and voila, instant product displays.

However, Don Papa wanted to go a little rogue. As Crystal Cabinet Works' product designer, Papa wanted to not only try something different for K/BIS that would stand out on the show floor and help differentiate the company from competitors, he wanted to try a Greener - not to mention cheaper - material for the exhibit's main structural components. "I wanted something that would really stand out on the show floor, and it would certainly help if that something was free or nearly free and somehow eco-friendly," Papa says.

Several months before the show, Papa found his one-size-fits-all answer in the pages of Dwell magazine. "I read this article about how people were using wooden shipping pallets to create low-income housing for homeless people in New Mexico," he says. "That led me to thinking about our own shipping pallets. We get tons of pallets, and as they accumulate, we grind them up and sell them to farmers to use for livestock bedding. We don't make a profit; we just charge enough to pay for the cost of grinding them. So I figured we had tons of free pallets in our shop, and if aid workers could make homes out of them, surely a bunch of skilled craftsmen could make a booth out of them."

With the flip of a magazine page, Papa had his solution. But before he went hog wild with the idea, he tested it on a smaller scale. Papa, a co-worker, and his daughter set about building 120, 1-inch-scale pallets out of bits of wood. They then arranged the pallets into a model exhibit featuring the company's traditional vignettes.

Confident that their design was both innovative, functional, and practically free, they approached the owner of the company with the detailed model in hand and held their breath for his approval.

"The minute he saw it, he loved it," Papa says. "And almost immediately, he gave us approval to start collecting pallets and constructing the booth." "The minute he saw it, he loved it," Papa says. "And almost immediately, he gave us approval to start collecting pallets and constructing the booth."

After internal engineers mocked up a more detailed design for the 20-by-50-foot booth and load tested it for safety and function, Papa and his construction crew rounded up the roughly 120 pallets needed. Next, the crew painted them with a thinned-out, water-based latex paint in a grey-blue hue. For while Papa was going for a unique aesthetic with the pallets, he felt the unfinished-wood look was too rustic for the kitchen vignettes and that a simple color wash would help the pallets peacefully co-exist - as opposed to compete - with the stylish cabinets.

To form the walls, the crew ran long pieces of lumber up the inside of each pallet and bolted the pallets to the lumber. The crew then bolted together the sides of these long vertical structures to create various-height walls. Next, they secured individual walls together at T-shaped angles to form the vignettes and to create the stability that prevented the walls from toppling over. A central bridge-like structure made of pallets, which ran overhead through the middle of the space, served as a central support column to further stabilize the design.

So with one innovative idea - and 120 pallets - Papa created a one-off palletized design that not only stopped traffic, it also served as a brilliant conversation starter. What's more, it provided a Green alternative to traditional exhibit materials, and it saved the company thousands of dollars in the process.

"If we'd built this booth out of typical exhibitry, it would have cost us hundreds of thousands of dollars," Papa says. "But with the reused pallets and internal labor, the materials and construction were practically free. And even compared to the vignette-style walls we've designed and built in the past, these walls cost about 80 percent less than what we'd typically spend."

The only drawback to Papa's design was the additional shipping costs en route to the show. "Since we couldn't break down the pallets to completely flat, compact elements, we had to use two trucks instead of one to ship our booth from Minnesota to Las Vegas," he says. However, he saved a bundle on the return trip, which only required one truck.

"We got rid of half of the wooden pallets after the show," Papa says. "We simply put the word out to fellow exhibitors that we had free pallets, and if they needed to ship something, they could come by and pick some up." The remaining pallets not claimed by other exhibitors at the show were shipped back to Crystal Cabinet Works' office, where they were ground up and sold to farmers.

From shipping pallet, to trade show booth, to barnyard bedding - now that's a Green strategy that saves some green in the process.

|

|

ttendees at the American Institute of Architects show are a discerning bunch. In fact, many won't cast a critical eye in your direction unless your exhibit design screams novel or intriguing. ttendees at the American Institute of Architects show are a discerning bunch. In fact, many won't cast a critical eye in your direction unless your exhibit design screams novel or intriguing.

So when Architecture Magazine set out to design an exhibit for the AIA show in Los Angeles, it knew conventional exhibitry simply wouldn't do. And given its meager $7,000 budget, which would need to cover everything from exhibit design and fabrication to transportation, "conventional" wasn't even part of its vocabulary. What's more, the unconventional exhibit would have to communicate a recent shift within the magazine itself.

Architecture Magazine (which had just been purchased and absorbed by Architect magazine) had recently undergone a redesign. Starting with the issue set to debut at AIA, the magazine would be organized around a thematic format, where each issue had a single theme and all content somehow connected to it.

So for AIA, Architecture Magazine hoped to create a one-time-use 10-by-20-foot property that not only relaunched the magazine and communicated the "reuse" theme of its first redesigned issue, but that also came in with a budget of $7,000. Faced with this daunting challenge, the magazine did what most people do when stuck between a rock and a hard place: It called in a favor from a friend. So for AIA, Architecture Magazine hoped to create a one-time-use 10-by-20-foot property that not only relaunched the magazine and communicated the "reuse" theme of its first redesigned issue, but that also came in with a budget of $7,000. Faced with this daunting challenge, the magazine did what most people do when stuck between a rock and a hard place: It called in a favor from a friend.

Architecture Magazine's senior editor, Julie Sinclair Eakin, had friends at Lookinglass Architecture and Design in Los Angeles. While Lookinglass does mostly commercial and residential architecture, she figured her friends' adventurous spirits might prompt them to tackle the design and perhaps even donate their time.

As she suspected, the challenge proved too alluring for Lookinglass to pass up. "While we typically don't do this kind of work, we're interested in doing work that has the potential to surprise people who come across it," says Lookinglass architect Emil Mertzel.

Thus, Lookinglass agreed to not only donate its time to design the project, but to secure the materials, build the exhibit, ship it to the show, and install it for the agreed-upon price of $7,000. "We'd never done a trade show booth before," Mertzel says, "so that was one heck of a staring point."

Mertzel and his team began by examining Architecture Magazine's reuse-themed issue. "We discovered that it wasn't just about recycling a material and turning it into something else," Mertzel says. "It was about taking an existing thing and somehow reusing it without altering it much. So we wanted a design concept that used a found object, particularly one you'd find in L.A."

Aside from celebrities and smog, Los Angeles is most known for its highway congestion. Thus, the team figured there was bound to be old guardrail lying around just waiting to be reused. The trick was finding it and creating an exhibit out of it.

They began by calling the California Department of Transportation, which agreed to donate some of its used guardrail in exchange for the positive publicity doing so might generate. So Mertzel and his partner Nick Gillock rented a truck and headed off to the Caltrans storage depot, where they found the guardrail in a rather dilapidated state. "It was covered in road grime, grease, oil, dents, etc. So it took us a while to pick out the pieces that were the least banged up," Mertzel says. The pair then transported the guardrail back to their L.A. office.

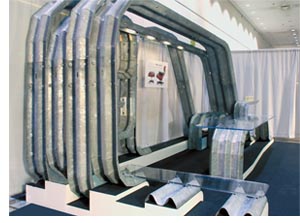

During the guardrail-acquisition process, Mertzel's team devised a design for the exhibit, taking inspiration from the magazine itself. "We turned to the process that actually makes the magazine - that is, the offset-printing process," Mertzel says. "We decided to create an exhibit that communicated the curving, winding way in which paper moves through a series of rollers to eventually produce a printed sheet." The team then designed a wooden platform upon which to secure the curved guardrail to keep the edges from splaying out from under it like the legs of a newborn calf.

When Mertzel and Gillock arrived back at the office with the guardrail, the team had a workable design - and a minor problem. Most guardrail forms a W shape when viewed in profile. "We thought we could bend guardrail like you bend steel: with a roller-based machine," Mertzel says. "But we soon realized that when you do that, the W shape flattens out and distorts the shape, and this simply wouldn't work in the design." So the team tested a couple of pieces and realized that by slicing a diamond-shape cutout into the rail, they could bend it and still retain its shape. Thus, Mertzel hit the phones again, calling on Charisma Design Studio Inc., which agreed to pick up the guardrail and water-jet cut it and bend it for a discounted price. While the guardrail was at Charisma's office, Mertzel brought in a pressure-cleaning company to power wash the guardrail prior to cutting. When Mertzel and Gillock arrived back at the office with the guardrail, the team had a workable design - and a minor problem. Most guardrail forms a W shape when viewed in profile. "We thought we could bend guardrail like you bend steel: with a roller-based machine," Mertzel says. "But we soon realized that when you do that, the W shape flattens out and distorts the shape, and this simply wouldn't work in the design." So the team tested a couple of pieces and realized that by slicing a diamond-shape cutout into the rail, they could bend it and still retain its shape. Thus, Mertzel hit the phones again, calling on Charisma Design Studio Inc., which agreed to pick up the guardrail and water-jet cut it and bend it for a discounted price. While the guardrail was at Charisma's office, Mertzel brought in a pressure-cleaning company to power wash the guardrail prior to cutting.

Meanwhile Mertzel called in another favor. He contacted Hinerfeld-Ward Inc., a local construction company, and convinced it to donate transportation from Charisma to Lookinglass for construction, and again from Lookinglass to the convention center for the show.

After the guardrail arrived back at Lookinglass, it was time to construct the exhibit and test its stability. But how do a handful of designers erect a booth with 33 individual guardrail components, the combined total of which equals 211 feet and 1,540 pounds? "We called up a bunch of our friends from grad school and invited them to a sort of assembling party," Mertzel says. "Architecture is a very slow business, so for all of us to actually build something in a couple of days over the weekend was fun and rewarding in itself."

By the time the party broke up, Mertzel and his team had constructed the entire exhibit - including an acrylic-topped reception desk and bench, and a back-wall structure with built-in shelves - tested its stability, and deconstructed it for transport. Shortly before the show, Hinerfeld-Ward returned to transport the partially assembled booth to the convention center.

Needless to say, Architecture Magazine was more than pleased with the result. For the reuse-themed exhibit not only drew the eye of demanding architects, it provided all the functional elements and still came in just shy of the $7,000 budget.

However, the reuse concept didn't stop there. The single-themed booth was never used again, but nary a scrap was carelessly discarded. While the bulk of the guardrail was recycled as scrap metal, the reception desk and a curved section of the back wall are now proudly displayed in Lookinglass' front office. So at least in the case of Lookinglass, you really can get by with a little help from your friends - and get some free artwork and a reception desk to boot.

|

|

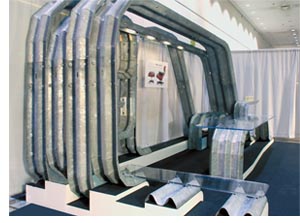

esigners, make it work." This iconic phrase coined by "Project Runway" host Tim Gunn was the underlying design directive handed down by Les Productions Interface Design. For not only did the exhibitor have no clue as to what its 20-by-30-foot booth should look like, it also had no budget to create it. So despite a lack of, well, anything except a few goals, some exhibit designer still had to "make it work." esigners, make it work." This iconic phrase coined by "Project Runway" host Tim Gunn was the underlying design directive handed down by Les Productions Interface Design. For not only did the exhibitor have no clue as to what its 20-by-30-foot booth should look like, it also had no budget to create it. So despite a lack of, well, anything except a few goals, some exhibit designer still had to "make it work."

Not surprisingly, this improvisational challenge was born of some rather complex circumstances. Les Productions Interface Design is both the producer of the Salon International du Design d'Intérieur de Montreal show (aka SIDIM, the Montreal equivalent of U.S.-based GlobalShop) and the publisher of Intérieurs magazine, an interior-design magazine based in Quebec. To further complicate matters, the public typically refers to Les Productions simply as SIDIM, which is actually the show it produces. Plus, shortly before the SIDIM show, Intérieurs launched a new interior-design competition, the Le Fonds d'Études et de Recherches en Design Intérieur de l'Est (aka Prix Intérieurs/FERDIE).

So Les Productions wanted a booth within its own show to accomplish three goals: 1) Combine all three entities cohesively: SIDIM, Intérieurs, and the Prix Intérieurs/FERDIE competition, 2) promote the Prix Intérieurs/FERDIE competition, and 3) function as a sort of central information hub where attendees could obtain floor maps, ask exhibitor- or show-related questions, etc. But far more problematic than these three objectives was SIDIM's budget, which was a whopping $0. Nevertheless, the company still hoped to create an effective exhibit out of myriad donated materials, services, and the goodwill of at least one talented designer. So Les Productions wanted a booth within its own show to accomplish three goals: 1) Combine all three entities cohesively: SIDIM, Intérieurs, and the Prix Intérieurs/FERDIE competition, 2) promote the Prix Intérieurs/FERDIE competition, and 3) function as a sort of central information hub where attendees could obtain floor maps, ask exhibitor- or show-related questions, etc. But far more problematic than these three objectives was SIDIM's budget, which was a whopping $0. Nevertheless, the company still hoped to create an effective exhibit out of myriad donated materials, services, and the goodwill of at least one talented designer.

Luckily for Les Productions, that talented designer turned out to be award-winning interior designer Robert Ruscio, principal of Ruscio Studio in Montreal. When Les Productions asked him to not only take on the challenge but to donate his own services, his initial feelings were, shall we say, less than positive.

"Build a booth for free? That's ridiculous," he said at the time. But soon, the lure of the challenge was too much, and Ruscio and his team agreed to take on the project in exchange for the publicity it would earn them through in-booth promotion and for the opportunity to design not only their first exhibit made of donated materials, but also their first exhibit - period.

Ruscio's first step was to gather the materials around which he'd eventually create a design. "SIDIM gave us a list of companies that had already agreed to donate show-related services as an act of goodwill toward the long-standing show organizer," Ruscio says. "But for the most part, my firm had to create a list of suppliers and then cajole them into donating something that might serve a functional or aesthetic purpose in the exhibit."

While not as taxing as designing an entire exhibit, compiling this list and convincing companies to donate materials in exchange for in-booth publicity proved a substantial challenge. "We quickly found that the companies from which we really needed materials had cold feet, and the companies from which we didn't need anything were all over us," Ruscio says.

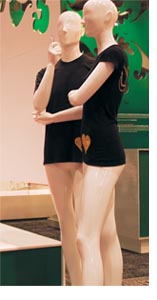

Eventually Ruscio and his team had assembled enough donated materials to fill the booth space, including MDF panels, paint, carpet tiles, borrowed lamps, an artist-crafted light fixture, track lights, laminate, graphics, and a couple of mannequins. It was finally time for them to stop cajoling and start designing and building the booth.

Ruscio began by dividing the space. "The half of the booth facing the exhibit hall's main entrance functioned as the show-information area," Ruscio says. "We used Kirei, laminate, and some paint to create a large reception counter where attendees could ask questions, look at maps of the exhibit hall, etc. Then we borrowed Bourgie lamps to add a touch of flair to the contemporary desk."

In this half of the space, Ruscio and his team positioned a vivid-green and off-white desk in front of an enormous convention-center column, which they covered in reflective gold laminate. On the inward-facing side of the column, they attached two graphic panels and some applied graphics to promote the three Les Productions entities. Meanwhile, the aisle side of the column held graphics featuring names of the companies that donated materials or services for the design. In this half of the space, Ruscio and his team positioned a vivid-green and off-white desk in front of an enormous convention-center column, which they covered in reflective gold laminate. On the inward-facing side of the column, they attached two graphic panels and some applied graphics to promote the three Les Productions entities. Meanwhile, the aisle side of the column held graphics featuring names of the companies that donated materials or services for the design.

The second half of the space was devoted to a semi-enclosed seating area, perfect for cozy conversations and informal gatherings. Here Ruscio's team suspended joined MDF panels into which a millworker cut an intricate pattern prior to the show. Painted a stark white on the outside and a lush green on the inside, the MDF enclosure featured Intérieurs/FERDIE award nominees on the green interior surfaces while overhead track lighting attached to the MDF added a dramatic flair. Laminated MDF benches and a central podium in matching green and white completed the scene.

To add a touch of whimsy to an otherwise serious space - and to make use of every donated item he'd worked so hard to obtain - Ruscio added a suspended light fixture an artist created just for the exhibit, along with two mannequins he managed to acquire clad in SIDIM T-shirts. And with that, the donated design was complete.

Not surprisingly, Les Productions was thrilled with the free booth - as was Ruscio himself, who transferred the carpeting to his office's conference room after the show was over. "Having a successful design doesn't necessarily mean spending a lot of money," Ruscio says. "Even with basic and perhaps disparate materials, you just have to apply creativity, consider the function, and add some finishing touches. And if you're good - and a little lucky - magic happens." Conjuring a booth out of thin air? That's magic indeed. E

|

|

|

f necessity is the mother of invention, then it is also father of imaginative exhibit design. For when the need to create an exhibit far outweighs your budget to do so, you have no choice but to throw off the shackles of cherished practices, open your mind to previously unthinkable alternatives, and belly flop yourself into the unexplored waters of invention.

f necessity is the mother of invention, then it is also father of imaginative exhibit design. For when the need to create an exhibit far outweighs your budget to do so, you have no choice but to throw off the shackles of cherished practices, open your mind to previously unthinkable alternatives, and belly flop yourself into the unexplored waters of invention.

or 62-year-old custom cabinet manufacturer Crystal Cabinet Works Inc., exhibit design and construction is almost a second calling. In fact, the Princeton, MN, firm has been designing and building its booths for roughly 15 years, for shows such as the Kitchen/Bath Industry Show & Conference and NeoCon.

or 62-year-old custom cabinet manufacturer Crystal Cabinet Works Inc., exhibit design and construction is almost a second calling. In fact, the Princeton, MN, firm has been designing and building its booths for roughly 15 years, for shows such as the Kitchen/Bath Industry Show & Conference and NeoCon.

ttendees at the American Institute of Architects show are a discerning bunch. In fact, many won't cast a critical eye in your direction unless your exhibit design screams novel or intriguing.

ttendees at the American Institute of Architects show are a discerning bunch. In fact, many won't cast a critical eye in your direction unless your exhibit design screams novel or intriguing.

esigners, make it work." This iconic phrase coined by "Project Runway" host Tim Gunn was the underlying design directive handed down by Les Productions Interface Design. For not only did the exhibitor have no clue as to what its 20-by-30-foot booth should look like, it also had no budget to create it. So despite a lack of, well, anything except a few goals, some exhibit designer still had to "make it work."

esigners, make it work." This iconic phrase coined by "Project Runway" host Tim Gunn was the underlying design directive handed down by Les Productions Interface Design. For not only did the exhibitor have no clue as to what its 20-by-30-foot booth should look like, it also had no budget to create it. So despite a lack of, well, anything except a few goals, some exhibit designer still had to "make it work."