cost cutting |

|

t's official: As of Dec. 1, 2008, the U.S. economy has been in a recession for more than a year. But given

our obvious state of affairs, we probably didn't need

the National Bureau of Economic Research to define the situation. Stocks are shriveling. Banks are failing. Automakers

are speeding down the Autobahn to an early grave. And unfortunately, the trade show world is not immune. t's official: As of Dec. 1, 2008, the U.S. economy has been in a recession for more than a year. But given

our obvious state of affairs, we probably didn't need

the National Bureau of Economic Research to define the situation. Stocks are shriveling. Banks are failing. Automakers

are speeding down the Autobahn to an early grave. And unfortunately, the trade show world is not immune.

Granted, the news isn't all doom and gloom for the exhibit industry. Data from the Center for Exhibition Industry Research's 2008 CEIR Index suggests that the long-term outlook for the exhibition industry is "very promising." Plus, no major shows have pulled a Lehman

Brothers and gone belly up in the last year or so. But waning attendance at shows is undeniably alarming, and according to EXHIBITOR's "2009 Budget and Trend Forecast," a whopping 41 percent of companies indicated their overall trade show budget would decrease in 2009. So even if the exhibit industry remains healthy despite an economy in cardiac arrest, many exhibitors are being challenged to cut costs - and cut deep.

"When an exhibitor is asked to reduce costs, it's usually by a lot," says Mark Bendickson, principal and designer at Exhibitdesign, a Maple Grove, MN, exhibit-design firm. "They typically can't eliminate a couple of staffers from the booth schedule and call it a day." So what do you do when management trots your exhibit-marketing program off to the chopping block and returns it minus 20 percent of its budget - or 30 or 50 percent for that matter?

That's exactly what EXHIBITOR asked 20 of the industry's movers and shakers from both sides of the tracks. In addition

to the scads of cost-cutting tips and techniques exhibitors and industry suppliers offered, they all had one overarching guideline: Don't take the easy route and eliminate entire line items. Rather, nip and tuck across the board, and never hack off something that reduces your program's effectiveness.

"Exhibit managers don't often think through how the cuts will impact their customer relationships," says Judy Volker, marketing director of Iatric Systems Inc. in Boxford, MA. "You have to maintain a customer-centric mindset and make your cuts from that perspective."

Bendickson feels so strongly about maintaining program effectiveness that he suggests you cut an entire show before eliminating a key component from your program. "Shows aren't static," he says. "They grow, contract, and become more or less relevant to your program for a variety of reasons. Take a close look at your shows and determine if they're all providing the type of ROI you expect in the current economy. You might be able to eliminate one show entirely in an effort to cut costs, and/or to allow you to reallocate funds and keep critical elements in your remaining shows. After all, cutting a bad show cuts everything from shipping and I&D to drayage and graphics production."

So, armed with a long-range mindset and a thorough understanding of which elements are critical to your program's success, it's time cut costs. And thanks to our industry experts, you've got 54 cost-cutting tactics to choose from. Although you certainly can't apply every tip and no one tip will magically eliminate your cash-strapped woes, you can select several ideas from various categories to help you trim the fat from your budget - without making a bloody mess of your program.

|

Buying Exhibits

Purchasing a new exhibit while trying to cut costs sounds counterproductive. But buying a new booth might be a smart move if your old property is hindering effectiveness or if a new property will cut your operating costs long term. Here

are several ways to decrease the costs of a new exhibit and

to plan for long-term savings.

|

Downsize your space. "The size of your booth space doesn't matter nearly as much as what you put in it," says Kimberly Kee, founder of Denver-based event company Kinetic Events (formerly Kee Consulting). "Downsize your booth size and ratchet up its effectiveness. After all, is there really much difference between, say, an 80-by-80 exhibit and a 50-by-50?" Brad Montgomery, CTSM, marketing and communications director at Accuform Signs in Brooksville, FL, agrees that even a little reduction in size can mean a big savings. "Your booth space is often the largest single-item expense in your show budget," he says. "So if you can reduce your booth space by even 100 square feet, that's probably a few grand in your pocket. Plus, that cut subsequently reduces other related costs such as carpet, shipping, drayage, cleaning, etc." Downsize your space. "The size of your booth space doesn't matter nearly as much as what you put in it," says Kimberly Kee, founder of Denver-based event company Kinetic Events (formerly Kee Consulting). "Downsize your booth size and ratchet up its effectiveness. After all, is there really much difference between, say, an 80-by-80 exhibit and a 50-by-50?" Brad Montgomery, CTSM, marketing and communications director at Accuform Signs in Brooksville, FL, agrees that even a little reduction in size can mean a big savings. "Your booth space is often the largest single-item expense in your show budget," he says. "So if you can reduce your booth space by even 100 square feet, that's probably a few grand in your pocket. Plus, that cut subsequently reduces other related costs such as carpet, shipping, drayage, cleaning, etc."

Switch to lighter-weight properties. "It sounds obvious, but by switching out our old heavy properties with lighter-weight ones, we expect to save $50,000 per year in storage, transportation, drayage, and installation and dismantle," says Janice Breuer, CTSM, trade show specialists with FFF Enterprises Inc. in Temecula, CA. Switch to lighter-weight properties. "It sounds obvious, but by switching out our old heavy properties with lighter-weight ones, we expect to save $50,000 per year in storage, transportation, drayage, and installation and dismantle," says Janice Breuer, CTSM, trade show specialists with FFF Enterprises Inc. in Temecula, CA.

Request pricing for multiple material options. Before you purchase your next exhibit, ask your suppliers to price out multiple material options in varying thicknesses, qualities, and prices, and to explain the pros and cons of each. Matt Daniels, project manager at Winntech, a Kansas City, MO-based retail, fixture, and merchandising-design firm, suggests that rather than automatically using Lexan, a popular brand of polycarbonate, for example, get pricing and information on multiple, perhaps generic, forms of polycarbonates. Or instead of using Plexiglas, investigate various acrylics. You might find that a cheaper, lesser-known material can still meet your needs. Request pricing for multiple material options. Before you purchase your next exhibit, ask your suppliers to price out multiple material options in varying thicknesses, qualities, and prices, and to explain the pros and cons of each. Matt Daniels, project manager at Winntech, a Kansas City, MO-based retail, fixture, and merchandising-design firm, suggests that rather than automatically using Lexan, a popular brand of polycarbonate, for example, get pricing and information on multiple, perhaps generic, forms of polycarbonates. Or instead of using Plexiglas, investigate various acrylics. You might find that a cheaper, lesser-known material can still meet your needs.

Buy a used property. Second owners can save 50 to 75 percent off the cost of building new. Check sites such as ExhibitAuction.com, ExhibitorOnline.com, Exhibits.com, Used-Trade-Show-Booths.com, and Webisales.com, which offer used exhibits including everything from custom properties ready for refurbishing to blank-slate tabletops and pop-ups. Also ask your exhibit house and industry peers to stay on the lookout for any exhibitors looking to sell their used exhibit properties. Buy a used property. Second owners can save 50 to 75 percent off the cost of building new. Check sites such as ExhibitAuction.com, ExhibitorOnline.com, Exhibits.com, Used-Trade-Show-Booths.com, and Webisales.com, which offer used exhibits including everything from custom properties ready for refurbishing to blank-slate tabletops and pop-ups. Also ask your exhibit house and industry peers to stay on the lookout for any exhibitors looking to sell their used exhibit properties.

Pay on time. As you pay for your new exhibit and services, try to continually provide payment on or ahead of schedule, as timely payment may be cause for a discount. "Similar to many industries, exhibit-industry suppliers sometimes suffer cash-flow problems," says Matthew Green, founder of Project Profile Ltd., a London-based face-to-face communications agency. "If you consistently pay on time, you can often negotiate 'timely' discounts for anywhere from 10 to 30 percent off your typical fees." E. Jane Lorimer, managing director of Lorimer Consulting Group in Denver, also suggests that paying up front might actually cost you less than paying over time. For example, if you pay your entire space cost up front rather than paying it in installments, you have the opportunity to negotiate for a lower total cost. Bottom line, if your timeliness and organization pay dividends for your suppliers, it could mean a discount for you. Pay on time. As you pay for your new exhibit and services, try to continually provide payment on or ahead of schedule, as timely payment may be cause for a discount. "Similar to many industries, exhibit-industry suppliers sometimes suffer cash-flow problems," says Matthew Green, founder of Project Profile Ltd., a London-based face-to-face communications agency. "If you consistently pay on time, you can often negotiate 'timely' discounts for anywhere from 10 to 30 percent off your typical fees." E. Jane Lorimer, managing director of Lorimer Consulting Group in Denver, also suggests that paying up front might actually cost you less than paying over time. For example, if you pay your entire space cost up front rather than paying it in installments, you have the opportunity to negotiate for a lower total cost. Bottom line, if your timeliness and organization pay dividends for your suppliers, it could mean a discount for you.

Consider rental exhibits. Given recent advancements in exhibit rental - including multi-use agreements, build-to-suit contracts, and custom/rental hybrid solutions - not to mention an almost industry-wide uptick in the quality of rental components over the last 15 years, renting can prove to be a viable and cost-effective solution. Not only does rental require a much smaller initial cash outlay, it also eliminates almost all costs of ownership, from storage and insurance costs to refurbishing and disposal fees. So before you buy, investigate not only the costs of rental but also the costs of ownership. Consider rental exhibits. Given recent advancements in exhibit rental - including multi-use agreements, build-to-suit contracts, and custom/rental hybrid solutions - not to mention an almost industry-wide uptick in the quality of rental components over the last 15 years, renting can prove to be a viable and cost-effective solution. Not only does rental require a much smaller initial cash outlay, it also eliminates almost all costs of ownership, from storage and insurance costs to refurbishing and disposal fees. So before you buy, investigate not only the costs of rental but also the costs of ownership.

Select multipurpose elements. "If you're building a booth anyway, consider each element's potential use, not just in various booth configurations but also in non-trade-show functions, such as customer events, sales presentations, private demos, etc.," says Tony Castrigno, senior partner and CEO of Designcontact, a New York exhibit-design firm. "If you can extend the use of an element beyond the trade show to other marketing- or sales-related events, you can double its value." Select multipurpose elements. "If you're building a booth anyway, consider each element's potential use, not just in various booth configurations but also in non-trade-show functions, such as customer events, sales presentations, private demos, etc.," says Tony Castrigno, senior partner and CEO of Designcontact, a New York exhibit-design firm. "If you can extend the use of an element beyond the trade show to other marketing- or sales-related events, you can double its value."

|

Graphics

When it comes to cutting graphics costs, options include everything from switching suppliers and repurposing images to investigating alternative substrates.

|

Reduce, reuse, repurpose. Rather than reinventing the wheel - or the graphic image - reuse artwork from current ad campaigns or other marketing efforts to cut costs on image creation and design. And don't limit your search for existing images to your department or office. Expand your search to other departments, divisions, and office locations within your company. Reduce, reuse, repurpose. Rather than reinventing the wheel - or the graphic image - reuse artwork from current ad campaigns or other marketing efforts to cut costs on image creation and design. And don't limit your search for existing images to your department or office. Expand your search to other departments, divisions, and office locations within your company.

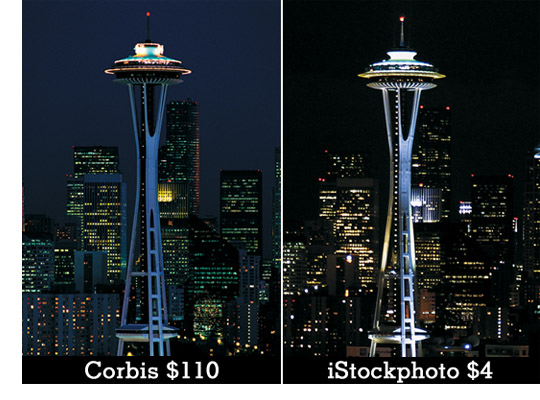

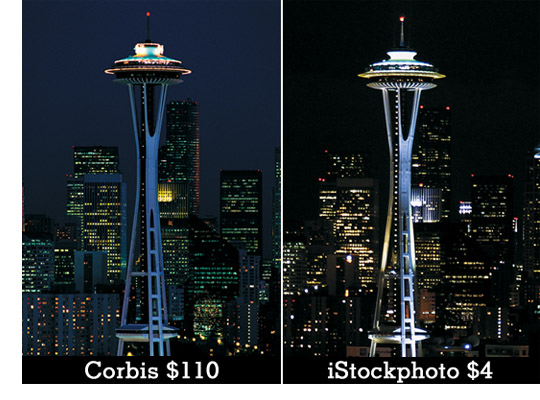

Consider stock photography. "If existing artwork isn't available, search low-cost stock-photography Web sites, rather than shooting the images yourself or buying stock shots from well-known, high-end sites such as Getty Images

Inc.," says Tim Provo, president of Elements Exhibits LLC in North Las Vegas, NV. "While Getty provides literally a million fabulous shots, lesser-known stock-photography sites such as iStockphoto.com can provide similar images at a fraction of the cost. Shopping around can mean the difference between a $300 image and a near-identical shot available for $10." Consider stock photography. "If existing artwork isn't available, search low-cost stock-photography Web sites, rather than shooting the images yourself or buying stock shots from well-known, high-end sites such as Getty Images

Inc.," says Tim Provo, president of Elements Exhibits LLC in North Las Vegas, NV. "While Getty provides literally a million fabulous shots, lesser-known stock-photography sites such as iStockphoto.com can provide similar images at a fraction of the cost. Shopping around can mean the difference between a $300 image and a near-identical shot available for $10."

Look outside the industry. "When it's time to buy new graphics for my banner stands, I use a local advertising/sign shop to create replacements, rather than purchasing

from the original dealer," Breuer says. "Switching suppliers saved me 65 percent off the original dealer's costs for each graphic, for a total savings of $2,100 last year. Of course, you need to find a local source whose quality equals the dealer's, but it's an option well worth investigating." Look outside the industry. "When it's time to buy new graphics for my banner stands, I use a local advertising/sign shop to create replacements, rather than purchasing

from the original dealer," Breuer says. "Switching suppliers saved me 65 percent off the original dealer's costs for each graphic, for a total savings of $2,100 last year. Of course, you need to find a local source whose quality equals the dealer's, but it's an option well worth investigating."

Consider vinyl. Inkjet/bubble-jet printing isn't the only way to go, nor is it always the cheapest route. Vinyl graphics offer another, albeit less-permanent option, Green says. Inexpensive vinyl lettering and graphics can be mounted to practically any surface, from photographs and substrates to mirrors and curved surfaces. They can be applied at the show or production facility and later peeled off for reuse or to simply change messaging or fix a typo. The inexpensive option, costing as little as a couple of dollars per letter, sure beats redoing an entire graphic panel every time you need to change messaging. Consider vinyl. Inkjet/bubble-jet printing isn't the only way to go, nor is it always the cheapest route. Vinyl graphics offer another, albeit less-permanent option, Green says. Inexpensive vinyl lettering and graphics can be mounted to practically any surface, from photographs and substrates to mirrors and curved surfaces. They can be applied at the show or production facility and later peeled off for reuse or to simply change messaging or fix a typo. The inexpensive option, costing as little as a couple of dollars per letter, sure beats redoing an entire graphic panel every time you need to change messaging.

Design generic graphics. "Avoid printing show-specific information on expensive graphics, as the minute the show closes, your graphics become obsolete," Provo says. Rather, add booth numbers, show dates, etc. to your graphics or other materials attached with hook-and-loop fasteners to allow the larger graphics to be reused and variable information to be easily changed at little to no cost. That way, instead of getting one show's use out of a particular graphic, you can divide its cost over several different shows. Design generic graphics. "Avoid printing show-specific information on expensive graphics, as the minute the show closes, your graphics become obsolete," Provo says. Rather, add booth numbers, show dates, etc. to your graphics or other materials attached with hook-and-loop fasteners to allow the larger graphics to be reused and variable information to be easily changed at little to no cost. That way, instead of getting one show's use out of a particular graphic, you can divide its cost over several different shows.

Produce graphics on location. To cut costs on shipping for at least one leg of your exhibit's journey, have your graphics produced in the city you are exhibiting prior to the show, says Geri-Dee Shaffer, director of Aesculap Academy and corporate programs at Aesculap Inc., a surgical-instruments provider in Center Valley, PA. To secure a reputable on-location producer, contact your exhibit house or graphics supplier for recommendations. Produce graphics on location. To cut costs on shipping for at least one leg of your exhibit's journey, have your graphics produced in the city you are exhibiting prior to the show, says Geri-Dee Shaffer, director of Aesculap Academy and corporate programs at Aesculap Inc., a surgical-instruments provider in Center Valley, PA. To secure a reputable on-location producer, contact your exhibit house or graphics supplier for recommendations.

Understand timelines. To avoid rush charges and added markups, you first need to understand exactly when and how those charges are incurred. So before you sign off on your graphics, ask the supplier to explain its timelines and markups so you can plan accordingly to avoid these extra charges and hidden fees. Understand timelines. To avoid rush charges and added markups, you first need to understand exactly when and how those charges are incurred. So before you sign off on your graphics, ask the supplier to explain its timelines and markups so you can plan accordingly to avoid these extra charges and hidden fees.

Use in-house talent. When it comes to designing your graphics, don't overlook in-house talents such as designers or copywriters. Using their skills can eliminate creative costs, leaving only production charges. Plus, given internal employees' solid understanding of your company, its products, and your marketing efforts, they can usually speed the design process as well. Use in-house talent. When it comes to designing your graphics, don't overlook in-house talents such as designers or copywriters. Using their skills can eliminate creative costs, leaving only production charges. Plus, given internal employees' solid understanding of your company, its products, and your marketing efforts, they can usually speed the design process as well.

Pick the right size. Before you purchase a particular material or size of graphic, find out what size sheets or rolls it comes in, and determine if the size meets your requirements without a lot of material waste or tiling, i.e. bonding together multiple pieces to create one large piece. "For example, Floorguard is a laminate that is only available in widths up to 51 inches," Daniels says. "If you need a 58-inch graphic, you'll need to purchase and tile two pieces, which will increase your material and labor costs." Instead, opt for a different material available in 58-inch rolls or simply downsize your graphic. Pick the right size. Before you purchase a particular material or size of graphic, find out what size sheets or rolls it comes in, and determine if the size meets your requirements without a lot of material waste or tiling, i.e. bonding together multiple pieces to create one large piece. "For example, Floorguard is a laminate that is only available in widths up to 51 inches," Daniels says. "If you need a 58-inch graphic, you'll need to purchase and tile two pieces, which will increase your material and labor costs." Instead, opt for a different material available in 58-inch rolls or simply downsize your graphic.

|

Storage

Most exhibitors assume storage costs are similar to exhibit-space costs, in that there's not much you can do to reduce them. But here are seven ways to save on storage and keep costs under control.

|

Negotiate your rate. Make storage an integral part of your overall exhibit-house

negotiations, whether you're renegotiating

an existing contract with our current exhibit

house or storage facility, or looking for a new

exhibit-storage partner, says independent

exhibit-management consultant Candy

Adams, CTSM, CME, CEM, CMP, CMM. Negotiate your rate. Make storage an integral part of your overall exhibit-house

negotiations, whether you're renegotiating

an existing contract with our current exhibit

house or storage facility, or looking for a new

exhibit-storage partner, says independent

exhibit-management consultant Candy

Adams, CTSM, CME, CEM, CMP, CMM.

Scope out other options. Don't

limit your storage options to your

exhibit house. Investigate other potentially less-expensive options such as

self-storage facilities, your company's

warehouse, a storage facility belonging

to another division of your company, an

empty trailer you can park on your company's property, a portable-storage pod,

etc. But before you move your properties into

the shed out back, consider how your exhibitry will react

to heat and cold in non-climate-controlled spaces. Scope out other options. Don't

limit your storage options to your

exhibit house. Investigate other potentially less-expensive options such as

self-storage facilities, your company's

warehouse, a storage facility belonging

to another division of your company, an

empty trailer you can park on your company's property, a portable-storage pod,

etc. But before you move your properties into

the shed out back, consider how your exhibitry will react

to heat and cold in non-climate-controlled spaces.

Understand storage extras. If you're storing your properties at your exhibit house, Adams says, ask what additional services are included in your storage costs, such as exhibit maintenance, inventory tracking, and show preparation. Depending on your properties, you might be paying extra fees for unnecessary add-ons, such as a climate-controlled warehouse, 24-hour security guard, prime storage space with easy access to multiple truck docks, etc. Plus, exhibit houses might also charge a sort of "usage" fee each time you access your properties, inventory them, load or unload them with your transportation carrier, or repair them, Adams says. While some of these services might be necessary for your program, you may be able to decrease the frequency of some "usage" fees or eliminate unnecessary services altogether. Understand storage extras. If you're storing your properties at your exhibit house, Adams says, ask what additional services are included in your storage costs, such as exhibit maintenance, inventory tracking, and show preparation. Depending on your properties, you might be paying extra fees for unnecessary add-ons, such as a climate-controlled warehouse, 24-hour security guard, prime storage space with easy access to multiple truck docks, etc. Plus, exhibit houses might also charge a sort of "usage" fee each time you access your properties, inventory them, load or unload them with your transportation carrier, or repair them, Adams says. While some of these services might be necessary for your program, you may be able to decrease the frequency of some "usage" fees or eliminate unnecessary services altogether.

Consider "touring." Compare where you exhibit versus where your exhibit lives. When your booth is "touring," you don't ship it back to your home base after every show. Instead, you store it closer to where you exhibit, often in facilities with a lower storage rate, such as your shipper's facility, the advance warehouse, another division of your company, etc. For example, let's say you have consecutive shows in the Midwest. Rather than shipping your booth to and from your California-based exhibit house, you ship it from one advance warehouse to the next between shows, perhaps storing it in your shipper's warehouse when deadlines don't quite match up in your favor. Touring isn't always the best option, and it might be suitable for only a few shows, but by doing the math, you can determine which method is most economical, and possibly incur both storage and shipping savings. Consider "touring." Compare where you exhibit versus where your exhibit lives. When your booth is "touring," you don't ship it back to your home base after every show. Instead, you store it closer to where you exhibit, often in facilities with a lower storage rate, such as your shipper's facility, the advance warehouse, another division of your company, etc. For example, let's say you have consecutive shows in the Midwest. Rather than shipping your booth to and from your California-based exhibit house, you ship it from one advance warehouse to the next between shows, perhaps storing it in your shipper's warehouse when deadlines don't quite match up in your favor. Touring isn't always the best option, and it might be suitable for only a few shows, but by doing the math, you can determine which method is most economical, and possibly incur both storage and shipping savings.

Take inventory and purge. Ask your exhibit house for a detailed list of everything you're storing at its facility, Lorimer suggests. "Then clear out any exhibitry, literature, signage, etc. that you don't need to reduce your storage space." If you identify items that are rarely used but that can't be disposed of entirely, consider storing them in a lower-cost facility such as a climate-controlled self-storage facility. Understand, however, that if you ask your exhibit house to dispose of properties or exhibit elements, it may charge you a fee to do so, Adams warns. Sometimes rather than paying the fee, she says, you can dispose of small elements yourself, or you might be able to sell elements or entire properties to the exhibit house for use as rental property. In any case, be sure you inquire about any disposal fees before you start the purging process. Take inventory and purge. Ask your exhibit house for a detailed list of everything you're storing at its facility, Lorimer suggests. "Then clear out any exhibitry, literature, signage, etc. that you don't need to reduce your storage space." If you identify items that are rarely used but that can't be disposed of entirely, consider storing them in a lower-cost facility such as a climate-controlled self-storage facility. Understand, however, that if you ask your exhibit house to dispose of properties or exhibit elements, it may charge you a fee to do so, Adams warns. Sometimes rather than paying the fee, she says, you can dispose of small elements yourself, or you might be able to sell elements or entire properties to the exhibit house for use as rental property. In any case, be sure you inquire about any disposal fees before you start the purging process.

Get the air out. Another way to cut storage and shipping costs is to pack wisely. "I've become a packing Nazi by ruthlessly cramming as much as possible into all of my containers," says Bob Milam, trade show manager at Kerry Ingredients and Flavours Inc. of Beloit, WI. "Of course, you have to be careful not to damage anything, but if you collapse down all exhibit materials to their smallest size and pack miscellaneous items into the corners of your containers, you'll reap two benefits: 1) Tightly packed shipments move around less in their containers, reducing the risk of damage, and 2) fewer boxes mean less volume - and less cost - in transportation and storage." Get the air out. Another way to cut storage and shipping costs is to pack wisely. "I've become a packing Nazi by ruthlessly cramming as much as possible into all of my containers," says Bob Milam, trade show manager at Kerry Ingredients and Flavours Inc. of Beloit, WI. "Of course, you have to be careful not to damage anything, but if you collapse down all exhibit materials to their smallest size and pack miscellaneous items into the corners of your containers, you'll reap two benefits: 1) Tightly packed shipments move around less in their containers, reducing the risk of damage, and 2) fewer boxes mean less volume - and less cost - in transportation and storage."

Audit your bill. Whenever you receive your storage bill, typically on a quarterly basis, immediately audit it for accuracy, Adams says. "Make sure your bill matches your contractual rates and correctly reflects your current exhibit inventory and dimensions." And while you're at it, review each line item to determine if there are any items that have recently become unnecessary and can be eliminated given your current storage requirements. Audit your bill. Whenever you receive your storage bill, typically on a quarterly basis, immediately audit it for accuracy, Adams says. "Make sure your bill matches your contractual rates and correctly reflects your current exhibit inventory and dimensions." And while you're at it, review each line item to determine if there are any items that have recently become unnecessary and can be eliminated given your current storage requirements.

|

Transportation and Drayage

With gas costs yo-yoing faster than Oprah's weight, transportation charges can really bite you in the budget. And once you get your exhibit to show site, weight-based drayage fees lurk around every corner, just waiting to nibble away at what you've got left. But if you use these tips to think light, think smart, and think outside of traditional methods, you can master your transportation and shipping costs before they gobble up your cash.

|

Compare renting versus shipping. "In international-shipping circumstances, it might be more cost effective to rent an exhibit locally than to ship even a pop-up from the United States," says Jeannine K. Swan, president of Global Exhibit Management in Fort Worth, TX. "For example, renting a roughly 10-by-20-foot stand in Hamburg, Germany, including custom graphics, can be less expensive than shipping two pop-ups from the United States after paying customs, handling, and delivery fees," Swan says. "I just quoted the price to ship three pieces weighing 2,650 pounds from Miami to Istanbul, Turkey. With the local handling and airport fees, simply getting the booth to the show costs more than $23,000, and we could rent a comparable exhibit in Istanbul for half that much." Compare renting versus shipping. "In international-shipping circumstances, it might be more cost effective to rent an exhibit locally than to ship even a pop-up from the United States," says Jeannine K. Swan, president of Global Exhibit Management in Fort Worth, TX. "For example, renting a roughly 10-by-20-foot stand in Hamburg, Germany, including custom graphics, can be less expensive than shipping two pop-ups from the United States after paying customs, handling, and delivery fees," Swan says. "I just quoted the price to ship three pieces weighing 2,650 pounds from Miami to Istanbul, Turkey. With the local handling and airport fees, simply getting the booth to the show costs more than $23,000, and we could rent a comparable exhibit in Istanbul for half that much."

Investigate transportation caravans. According to Jay James, vice president of exhibitor sales at Freeman in Dallas, some general contractors offer round-trip transportation sharing for exhibitors who exhibit at the same shows. "Caravans lower the costs of shipping and eliminate possible overtime charges, off-target fees, and special-handling charges that exhibitors routinely absorb," he says. A quick call to your general contractor could save you thousands of dollars. Investigate transportation caravans. According to Jay James, vice president of exhibitor sales at Freeman in Dallas, some general contractors offer round-trip transportation sharing for exhibitors who exhibit at the same shows. "Caravans lower the costs of shipping and eliminate possible overtime charges, off-target fees, and special-handling charges that exhibitors routinely absorb," he says. A quick call to your general contractor could save you thousands of dollars.

Throw it away. "After the show, throw away as much as you can rather than shipping it back," Milam says. "Do you really need those 17 sell sheets and samples that will only end up in the back of the warehouse? Does it make sense to ship 20 tchotchkes that only cost a buck apiece back to the office? Consider the cost to ship each item home compared to its replacement value and the likelihood of use or reuse, and toss whatever Throw it away. "After the show, throw away as much as you can rather than shipping it back," Milam says. "Do you really need those 17 sell sheets and samples that will only end up in the back of the warehouse? Does it make sense to ship 20 tchotchkes that only cost a buck apiece back to the office? Consider the cost to ship each item home compared to its replacement value and the likelihood of use or reuse, and toss whatever

doesn't make sense to ship."

Consider rail shipping. Shipping a truckload via rail

is cheaper than traditional

tractor-trailer or air-freight

shipments, perhaps by as

much as 20 percent, says

Mike Ellis, president of

EA Logistics in Chicago.

Keep in mind that it's best for

exhibitors that have an entire truckload and can allow a large buffer of time - perhaps up to a week - to absorb unanticipated delays, which are usually longer than other transportation methods. However, even shipping your booth back from the show via rail - when your deadlines aren't as tight or critical - can save you a load of money. Consider rail shipping. Shipping a truckload via rail

is cheaper than traditional

tractor-trailer or air-freight

shipments, perhaps by as

much as 20 percent, says

Mike Ellis, president of

EA Logistics in Chicago.

Keep in mind that it's best for

exhibitors that have an entire truckload and can allow a large buffer of time - perhaps up to a week - to absorb unanticipated delays, which are usually longer than other transportation methods. However, even shipping your booth back from the show via rail - when your deadlines aren't as tight or critical - can save you a load of money.

Audit weight tickets. Ask your exhibit house for the estimated weight of your properties before they're picked up by the shipper. Then verify this figure on your transportation bill as well as on your drayage bill. Sometimes your drayage bill is erroneously calculated on the full weight of the truck, not just the exhibit, Adams says. "This happens when someone on the docks or at the general service contractor's desk picks up the wrong figure from the certified weight slip. And simply looking for this mistake can save you thousands of dollars." Adams suggests you also audit yourtransportation and drayage bills and ensure that: 1) marshaling-yard fees haven't accidentally been charged to your account for small-package shipments, which actually came direct to the convention center, and 2) your freight has been charged in the right material-handling category, such as crated/floor loaded versus special handling/stacked, or pad wrapped. Audit weight tickets. Ask your exhibit house for the estimated weight of your properties before they're picked up by the shipper. Then verify this figure on your transportation bill as well as on your drayage bill. Sometimes your drayage bill is erroneously calculated on the full weight of the truck, not just the exhibit, Adams says. "This happens when someone on the docks or at the general service contractor's desk picks up the wrong figure from the certified weight slip. And simply looking for this mistake can save you thousands of dollars." Adams suggests you also audit yourtransportation and drayage bills and ensure that: 1) marshaling-yard fees haven't accidentally been charged to your account for small-package shipments, which actually came direct to the convention center, and 2) your freight has been charged in the right material-handling category, such as crated/floor loaded versus special handling/stacked, or pad wrapped.

Leverage corporate contracts. Your company or one of its divisions might have corporate, discounted

contracts with van lines or air-freight carriers. Investigate these contracts and take advantage of any savings. Leverage corporate contracts. Your company or one of its divisions might have corporate, discounted

contracts with van lines or air-freight carriers. Investigate these contracts and take advantage of any savings.

Consolidate or reroute small shipments. The minimum drayage weight (typically 200 pounds) is charged to each shipment, says Mike Thimmesch, director

of marketing communications at Skyline Exhibits in Eagan,

MN. So when it comes to drayage, one shipment is almost

always cheaper than three or four, so be sure to consolidate

whenever possible. Thimmesch also suggests shipping small

items to your hotel or asking staffers to transport them to the

show, as hand carrying them to

your booth eliminates the

drayage charge. Consolidate or reroute small shipments. The minimum drayage weight (typically 200 pounds) is charged to each shipment, says Mike Thimmesch, director

of marketing communications at Skyline Exhibits in Eagan,

MN. So when it comes to drayage, one shipment is almost

always cheaper than three or four, so be sure to consolidate

whenever possible. Thimmesch also suggests shipping small

items to your hotel or asking staffers to transport them to the

show, as hand carrying them to

your booth eliminates the

drayage charge.

|

Installation and Dismantle

Labor charges seem pretty cut and dried, but that doesn't mean you can't find ways to reduce some costs and skirt others entirely. Here are four ways to manhandle your I&D charges.

|

Bring your own supplies. Adams suggests you bring your own gang box stocked with supplies, rather than paying the markup for purchasing I&D supplies on site. At minimum, she suggests your gang box should include: tape for your carpet and pad, Visqueen to protect your carpet, hook-and-loop fastener for hanging graphics, extra light bulbs and fixtures, stretch wrap, package strapping, touch-up paint or felt-tip markers, cleaning supplies, and a spare sheet of laminate for on-site repairs. Since a roll of duct tape can cost $12 if purchased at the show, compared to $4 if purchased at a hardware store, this tip can save you a mighty chunk of change over time. Bring your own supplies. Adams suggests you bring your own gang box stocked with supplies, rather than paying the markup for purchasing I&D supplies on site. At minimum, she suggests your gang box should include: tape for your carpet and pad, Visqueen to protect your carpet, hook-and-loop fastener for hanging graphics, extra light bulbs and fixtures, stretch wrap, package strapping, touch-up paint or felt-tip markers, cleaning supplies, and a spare sheet of laminate for on-site repairs. Since a roll of duct tape can cost $12 if purchased at the show, compared to $4 if purchased at a hardware store, this tip can save you a mighty chunk of change over time.

Reuse laborers. "If you hire an exhibitor-appointed contractor for I&D, try to use the same laborers and lead for each installation," says Karen Carey, CTSM, an events consultant in Franklin, PA. "Their experience with your exhibit will cut your I&D time considerably." If you use show-provided labor, request the same crew for installation and tear down. Installation laborers familiar with your booth can disassemble it much faster than a whole new crew, cutting your total I&D time by as much as half. Reuse laborers. "If you hire an exhibitor-appointed contractor for I&D, try to use the same laborers and lead for each installation," says Karen Carey, CTSM, an events consultant in Franklin, PA. "Their experience with your exhibit will cut your I&D time considerably." If you use show-provided labor, request the same crew for installation and tear down. Installation laborers familiar with your booth can disassemble it much faster than a whole new crew, cutting your total I&D time by as much as half.

Use the maximum straight-time hours. "Plan your I&D so you're using fewer laborers for longer hours," Milam says. "I&D laborers want to work the maximum number of hours possible during each show to increase their paychecks. The jobs are often doled out to workers by seniority; thus, laborers with the most experience get first choice of jobs, and they tend to choose those jobs with the longest hours. So instead of scheduling six laborers for 12 hours each, use four laborers for 18 hours each. Your costs are the same initially, but you'll get more experienced workers, which might cut time and expenses in the long run." Use the maximum straight-time hours. "Plan your I&D so you're using fewer laborers for longer hours," Milam says. "I&D laborers want to work the maximum number of hours possible during each show to increase their paychecks. The jobs are often doled out to workers by seniority; thus, laborers with the most experience get first choice of jobs, and they tend to choose those jobs with the longest hours. So instead of scheduling six laborers for 12 hours each, use four laborers for 18 hours each. Your costs are the same initially, but you'll get more experienced workers, which might cut time and expenses in the long run."

Check the bill. "To help track down billing

errors, keep copies of pre-show labor orders and 'hard cards,'

the itemized labor bills completed

daily to indicate each laborer's start and

stop times and the total straight time and

overtime hours," Adams says. "Also check

the local labor contract to see when

straight time, overtime, and double-time

hours were supposed to begin and end.

Then make sure your bill is accurate given

the rules and reported times." Check the bill. "To help track down billing

errors, keep copies of pre-show labor orders and 'hard cards,'

the itemized labor bills completed

daily to indicate each laborer's start and

stop times and the total straight time and

overtime hours," Adams says. "Also check

the local labor contract to see when

straight time, overtime, and double-time

hours were supposed to begin and end.

Then make sure your bill is accurate given

the rules and reported times."

|

Show Services

Almost every exhibitor needs to purchase a show service or two, but cutting costs on these line items isn't always easy.

The following tips can help you snip a few dollars and cents.

|

Eliminate rigged lighting. "Before you invest in rigging, talk to your exhibit designer to see if you can integrate lighting into the top of some of your booth elements," Castrigno says. "Or better yet, build internally lit elements and carefully positioned LEDs and low-voltage fixtures into your design to drive down both rigging and electrical charges." Milam also suggests ordering par-can or Leko lights from the show's electrical contractor. "These usually cost about $350 apiece, which includes rigging, and 10 to 12 of them can effectively light a 50-by-50-foot area much cheaper than a $15,000 truss using your own (or rented) lights. Plus, you won't incur additional drayage or shipping costs." Eliminate rigged lighting. "Before you invest in rigging, talk to your exhibit designer to see if you can integrate lighting into the top of some of your booth elements," Castrigno says. "Or better yet, build internally lit elements and carefully positioned LEDs and low-voltage fixtures into your design to drive down both rigging and electrical charges." Milam also suggests ordering par-can or Leko lights from the show's electrical contractor. "These usually cost about $350 apiece, which includes rigging, and 10 to 12 of them can effectively light a 50-by-50-foot area much cheaper than a $15,000 truss using your own (or rented) lights. Plus, you won't incur additional drayage or shipping costs."

Use a portable server. According to Tradeshow Week's 2008 Furniture and Accessory Rates survey, Internet-access fees average a whopping $810.97 per show in the United States. "So instead of paying for an Internet connection, dump your entire Web site onto a portable server and hook up all in-booth computers to it," Bendickson suggests. Use a portable server. According to Tradeshow Week's 2008 Furniture and Accessory Rates survey, Internet-access fees average a whopping $810.97 per show in the United States. "So instead of paying for an Internet connection, dump your entire Web site onto a portable server and hook up all in-booth computers to it," Bendickson suggests.

Prune your floral costs. If you're renting plants for your exhibit, consider purchasing high-quality faux foliage that travels with you from show to show instead. Trimming your plant expenses doesn't sound like much of a cost savings unless you do the math. For example, renting a 4-foot green plant and a mum costs $52.17 and $25.70, respectively, per U.S. show (according to Tradeshow Week's 2008 Furniture and Accessory Rates survey). On the other hand, purchasing a silk Boston fern is a one-time fee of roughly $23, and you can buy a 4-foot faux ficus for less than $70. If you attend 20 shows a year, buying the two plants will cost you $93, and renting them will cost you more than $1,500. Prune your floral costs. If you're renting plants for your exhibit, consider purchasing high-quality faux foliage that travels with you from show to show instead. Trimming your plant expenses doesn't sound like much of a cost savings unless you do the math. For example, renting a 4-foot green plant and a mum costs $52.17 and $25.70, respectively, per U.S. show (according to Tradeshow Week's 2008 Furniture and Accessory Rates survey). On the other hand, purchasing a silk Boston fern is a one-time fee of roughly $23, and you can buy a 4-foot faux ficus for less than $70. If you attend 20 shows a year, buying the two plants will cost you $93, and renting them will cost you more than $1,500.

Buy a vacuum. "Vacuuming doesn't seem expensive, but it adds up over time," Milam says. "For example, if you pay $0.35 per square foot for a 1,000-square-foot booth at a three-day show, that's $350 per show. If you do 10 shows a year, that's $3,500." Instead, purchase a portable vacuum for about $150 and cut costs for every show. Carey concurs with the vacuuming strategy, but if show and union rules allow, she suggests that you assign the chore to an ineffective staffer. Buy a vacuum. "Vacuuming doesn't seem expensive, but it adds up over time," Milam says. "For example, if you pay $0.35 per square foot for a 1,000-square-foot booth at a three-day show, that's $350 per show. If you do 10 shows a year, that's $3,500." Instead, purchase a portable vacuum for about $150 and cut costs for every show. Carey concurs with the vacuuming strategy, but if show and union rules allow, she suggests that you assign the chore to an ineffective staffer.

|

Staffing and Travel

If you're not careful, staffers' travel and per-diem expenses can eat you out of house and home. But with a bit of frugality, some inventive alternatives, and nifty tactics, you can prevent staffing and travel costs from consuming your program's entire budget.

|

Outsource booth staffing. Granted, you can almost never completely outsource your exhibit staffing - or even drastically reduce the number of staffers - if you want to remain effective. However, using local, temporary staffers to perform tasks such as greeting visitors and manning giveaway-fulfillment counters can help cut staff travel costs while maintaining effectiveness, Lorimer suggests. Temporary staffers aren't free, but their services typically cost much less than the travel and per-diem costs involved with sending an employee to the show. Outsource booth staffing. Granted, you can almost never completely outsource your exhibit staffing - or even drastically reduce the number of staffers - if you want to remain effective. However, using local, temporary staffers to perform tasks such as greeting visitors and manning giveaway-fulfillment counters can help cut staff travel costs while maintaining effectiveness, Lorimer suggests. Temporary staffers aren't free, but their services typically cost much less than the travel and per-diem costs involved with sending an employee to the show.

Reward frugality. Offer a percentage rebate to employees who stay under their allotted per diem. For example, reward staffers with 50 percent of whatever they don't spend at the show. So if they were allotted $300, but only spent $100, halve the difference with them and give them $100 cash to reward their thriftiness. Your program still nets a cool $100 worth of savings, and the rebate program encourages staffers to keep an eye on their expenses. Reward frugality. Offer a percentage rebate to employees who stay under their allotted per diem. For example, reward staffers with 50 percent of whatever they don't spend at the show. So if they were allotted $300, but only spent $100, halve the difference with them and give them $100 cash to reward their thriftiness. Your program still nets a cool $100 worth of savings, and the rebate program encourages staffers to keep an eye on their expenses.

Staff locally. If your company has offices across the United States, consider using booth staff from a local or regional office rather than flying employees across the country to attend the show, Kee suggests. Even if you have to fly people in from nearby offices, shorter and perhaps cheaper flights might mean fewer nights in expensive hotels and less per-diem expenses. Staff locally. If your company has offices across the United States, consider using booth staff from a local or regional office rather than flying employees across the country to attend the show, Kee suggests. Even if you have to fly people in from nearby offices, shorter and perhaps cheaper flights might mean fewer nights in expensive hotels and less per-diem expenses.

Stop buying uniforms. "Tell booth staffers to wear business attire, and maybe make a few rules about appropriate shoes, colors, or skirt length," Milam says. "By letting people wear their own clothes, you've eliminated a reoccurring expense." Lorimer concurs, but also suggests that you buy 1-by-3-inch name badges with your company name and logo and the name of each booth staffer. According to Lorimer, "The badges clearly identify staffers as part of your company, and they're cheaper to order than a bunch of shirts." Stop buying uniforms. "Tell booth staffers to wear business attire, and maybe make a few rules about appropriate shoes, colors, or skirt length," Milam says. "By letting people wear their own clothes, you've eliminated a reoccurring expense." Lorimer concurs, but also suggests that you buy 1-by-3-inch name badges with your company name and logo and the name of each booth staffer. According to Lorimer, "The badges clearly identify staffers as part of your company, and they're cheaper to order than a bunch of shirts."

Negotiate international hotels directly. "When you're securing hotels internationally, housing bureaus can be helpful, but negotiating directly with a hotel is usually more cost effective," Swan says. "Speak the international hotel language of 'total nights,' so when you contact the hotel, negotiate using the number of total nights you will need. For example, if five people will stay for five nights, you need 25 nights. Ask for the lowest rate possible for your size of group, but also ask

about extras the hotel

might include, such as

airport transfers, Internet

access, and continental

breakfast. And remember, a cheaper

room might not be

cheaper in the long

run. For example,

if you opt for a room

plan that does not

include breakfast

or Internet access,

your staffers may

eat up the savings that

cheaper room offers by

paying for these extras out

of their per diem. Negotiate international hotels directly. "When you're securing hotels internationally, housing bureaus can be helpful, but negotiating directly with a hotel is usually more cost effective," Swan says. "Speak the international hotel language of 'total nights,' so when you contact the hotel, negotiate using the number of total nights you will need. For example, if five people will stay for five nights, you need 25 nights. Ask for the lowest rate possible for your size of group, but also ask

about extras the hotel

might include, such as

airport transfers, Internet

access, and continental

breakfast. And remember, a cheaper

room might not be

cheaper in the long

run. For example,

if you opt for a room

plan that does not

include breakfast

or Internet access,

your staffers may

eat up the savings that

cheaper room offers by

paying for these extras out

of their per diem.

Share rooms. Granted, not everyone wants to share a room. But you can cut costs considerably if you offer some kind of incentive - cash, a spa treatment, a room upgrade - for staffers who volunteer to share a room with a co-worker. If staffers are staying several nights, even a relatively expensive incentive is probably less than the cost of a second hotel room. Share rooms. Granted, not everyone wants to share a room. But you can cut costs considerably if you offer some kind of incentive - cash, a spa treatment, a room upgrade - for staffers who volunteer to share a room with a co-worker. If staffers are staying several nights, even a relatively expensive incentive is probably less than the cost of a second hotel room.

Get 'em out early. Send staffers home from the show as early as possible to save daily per-diem costs, hotel costs, etc. If show traffic is historically low on the last day, send non-essential staffers home a day early. "Or if staffers set up your booth themselves, try to be sure there's a hidden storage area in your space where they can store empty containers after installation," Volker says. "That way staffers can pull out the containers and pack up the booth as soon as the show is over, rather than waiting for empty crates to be returned. Then they can likely catch a flight out that night instead of paying for another night at the hotel and flying out the next morning." Get 'em out early. Send staffers home from the show as early as possible to save daily per-diem costs, hotel costs, etc. If show traffic is historically low on the last day, send non-essential staffers home a day early. "Or if staffers set up your booth themselves, try to be sure there's a hidden storage area in your space where they can store empty containers after installation," Volker says. "That way staffers can pull out the containers and pack up the booth as soon as the show is over, rather than waiting for empty crates to be returned. Then they can likely catch a flight out that night instead of paying for another night at the hotel and flying out the next morning."

Host staff dinners. Find a restaurant near the hotel and arrange a staff dinner - or several dinners - with a cost-conscious pre-selected menu. By selecting the menu for your staff, you can opt out of high-priced options such as prime rib and lobster, inserting lower-cost items such as pasta or chicken dishes instead. It's even possible that the chosen restaurant will offer you a discount of some sort for bringing in a large group. Jason Raddenbach, trade show coordinator for Warner Electric LLC, has employed this strategy at some of his shows, garnering a 24-percent decline in the cost of staff meals. Host staff dinners. Find a restaurant near the hotel and arrange a staff dinner - or several dinners - with a cost-conscious pre-selected menu. By selecting the menu for your staff, you can opt out of high-priced options such as prime rib and lobster, inserting lower-cost items such as pasta or chicken dishes instead. It's even possible that the chosen restaurant will offer you a discount of some sort for bringing in a large group. Jason Raddenbach, trade show coordinator for Warner Electric LLC, has employed this strategy at some of his shows, garnering a 24-percent decline in the cost of staff meals.

|

Giveaways and Literature

There's nothing free about freebies. So cut costs whenever and however you can with the following tips.

|

Eliminate literature. Paper is heavy, and lugging it to the show and your booth is expensive. "Cut your shipping and drayage costs by putting your literature on a branded USB drive," says Amy Gregory, senior veterinary conference planner for Hill's Pet Nutrition Inc. in Topeka, KS. "We purchased 512 MB flash drives for $5.80 each, which includes the costs of loading our files by a third-party vendor. Not only do we use less paper, but the perceived value of the information has gone up simply because it's on an electronic device rather than a piece of paper." Eliminate literature. Paper is heavy, and lugging it to the show and your booth is expensive. "Cut your shipping and drayage costs by putting your literature on a branded USB drive," says Amy Gregory, senior veterinary conference planner for Hill's Pet Nutrition Inc. in Topeka, KS. "We purchased 512 MB flash drives for $5.80 each, which includes the costs of loading our files by a third-party vendor. Not only do we use less paper, but the perceived value of the information has gone up simply because it's on an electronic device rather than a piece of paper."

Limit literature. If you can't eliminate literature altogether, at least decrease the volume you use. "Scarcity increases value," Milam says. "So don't print and ship thousands of flyers or sell sheets. Take the quantity you expect to use and cut it in half. Then tell staff that 'That's all there is, so make sure the literature gets into the right hands.' The strategy has cut our literature costs in half - including not only our shipping and drayage costs, but our literature-production costs as well. Plus, I think it encourages staffers to better qualify attendees that visit the booth before simply handing them a piece of paper and sending them on their way." Limit literature. If you can't eliminate literature altogether, at least decrease the volume you use. "Scarcity increases value," Milam says. "So don't print and ship thousands of flyers or sell sheets. Take the quantity you expect to use and cut it in half. Then tell staff that 'That's all there is, so make sure the literature gets into the right hands.' The strategy has cut our literature costs in half - including not only our shipping and drayage costs, but our literature-production costs as well. Plus, I think it encourages staffers to better qualify attendees that visit the booth before simply handing them a piece of paper and sending them on their way."

Order early and in bulk. Obviously, you don't want tons of trinkets sitting around your office for years on end. But if you know you'll be using the same giveaway for an entire year or more - or you might be able to repurpose it for other non-trade-show related promotions - order in bulk, as the more you order, the less expensive each one will be. And as always, order early, planning in a bit of buffer time to absorb unexpected delays so you don't end up paying for rush charges on production and shipping. Order early and in bulk. Obviously, you don't want tons of trinkets sitting around your office for years on end. But if you know you'll be using the same giveaway for an entire year or more - or you might be able to repurpose it for other non-trade-show related promotions - order in bulk, as the more you order, the less expensive each one will be. And as always, order early, planning in a bit of buffer time to absorb unexpected delays so you don't end up paying for rush charges on production and shipping.

Comparison shop. No matter how small or seemingly trivial your tchotchke might be, always comparison shop. To illustrate the point, EXHIBITOR staff priced a 2-inch rubber duck from several suppliers and found a staggering price range. One supplier charged $1.02 apiece for 500 logo-adorned ducks, while another supplier charged $2.99 for nearly identical ducks minus the custom logo. On a 500-duck order, that's a difference of $510 versus $1,495, respectively. Comparison shop. No matter how small or seemingly trivial your tchotchke might be, always comparison shop. To illustrate the point, EXHIBITOR staff priced a 2-inch rubber duck from several suppliers and found a staggering price range. One supplier charged $1.02 apiece for 500 logo-adorned ducks, while another supplier charged $2.99 for nearly identical ducks minus the custom logo. On a 500-duck order, that's a difference of $510 versus $1,495, respectively.

Give judiciously. Granted, at some shows attendees expect to receive something - anything - at almost every booth. But before you dole out swag to just anyone, consider every dime you spend designing, producing,

and delivering it to your booth. Likely, you're better served by giving tchotchkes only to qualified leads or people willing to earn them through an activity that provides you with added value or educates attendees about your product. Doing so will reduce the quantity of giveaways distributed, and thus their costs. Give judiciously. Granted, at some shows attendees expect to receive something - anything - at almost every booth. But before you dole out swag to just anyone, consider every dime you spend designing, producing,

and delivering it to your booth. Likely, you're better served by giving tchotchkes only to qualified leads or people willing to earn them through an activity that provides you with added value or educates attendees about your product. Doing so will reduce the quantity of giveaways distributed, and thus their costs.

Read the rules. Before you purchase that $500 popcorn cart,

read the rules and regulations in your exhibit guide to learn what giveaways are prohibited or discouraged by show management, Adams suggests. Prohibited items typically include anything that might need to be scraped off the floor, such as gum or stickers; removed from the ceiling, such as helium balloons; or swept or vacuumed up, such as popcorn or peanuts. Simply reading the rules can prevent you from blowing your budget on banned items. Even if the items you've planned for are allowed, they might come with the stipulation that you hire a porter to vacuum popcorn off aisle carpet - and that porter is going to come with a price tag. Read the rules. Before you purchase that $500 popcorn cart,

read the rules and regulations in your exhibit guide to learn what giveaways are prohibited or discouraged by show management, Adams suggests. Prohibited items typically include anything that might need to be scraped off the floor, such as gum or stickers; removed from the ceiling, such as helium balloons; or swept or vacuumed up, such as popcorn or peanuts. Simply reading the rules can prevent you from blowing your budget on banned items. Even if the items you've planned for are allowed, they might come with the stipulation that you hire a porter to vacuum popcorn off aisle carpet - and that porter is going to come with a price tag.

Ask about overages. When custom promotional pieces are produced, most suppliers produce extra items as part of the manufacturing process to ensure that your order has been completely filled before they reset the equipment for another order. Many companies simply include these extra items, or "overage," as a freebie to customers, but some companies charge you for every item you receive including the overage, even if you don't necessarily want it. So before you purchase a custom promotional product, make sure your supplier won't surprise you with an overage charge. Ask about overages. When custom promotional pieces are produced, most suppliers produce extra items as part of the manufacturing process to ensure that your order has been completely filled before they reset the equipment for another order. Many companies simply include these extra items, or "overage," as a freebie to customers, but some companies charge you for every item you receive including the overage, even if you don't necessarily want it. So before you purchase a custom promotional product, make sure your supplier won't surprise you with an overage charge.

Give wisely. "Be certain your premiums integrate with your message, as swag is an unnecessary cost if it doesn't deliver value," Milam says. "Rather than pens and squeezy balls that have nothing to do with your program, a few targeted items directly related to your program and distributed to qualified prospects - or better yet, some kind of free trial offer of your product - will deliver greater ROI and as a result, cut costs and hassles." e Give wisely. "Be certain your premiums integrate with your message, as swag is an unnecessary cost if it doesn't deliver value," Milam says. "Rather than pens and squeezy balls that have nothing to do with your program, a few targeted items directly related to your program and distributed to qualified prospects - or better yet, some kind of free trial offer of your product - will deliver greater ROI and as a result, cut costs and hassles." e

|

|

|

|

t's official: As of Dec. 1, 2008, the U.S. economy has been in a recession for more than a year. But given

our obvious state of affairs, we probably didn't need

the National Bureau of Economic Research to define the situation. Stocks are shriveling. Banks are failing. Automakers

are speeding down the Autobahn to an early grave. And unfortunately, the trade show world is not immune.

t's official: As of Dec. 1, 2008, the U.S. economy has been in a recession for more than a year. But given

our obvious state of affairs, we probably didn't need

the National Bureau of Economic Research to define the situation. Stocks are shriveling. Banks are failing. Automakers

are speeding down the Autobahn to an early grave. And unfortunately, the trade show world is not immune.  Downsize your space. "The size of your booth space doesn't matter nearly as much as what you put in it," says Kimberly Kee, founder of Denver-based event company Kinetic Events (formerly Kee Consulting). "Downsize your booth size and ratchet up its effectiveness. After all, is there really much difference between, say, an 80-by-80 exhibit and a 50-by-50?" Brad Montgomery, CTSM, marketing and communications director at Accuform Signs in Brooksville, FL, agrees that even a little reduction in size can mean a big savings. "Your booth space is often the largest single-item expense in your show budget," he says. "So if you can reduce your booth space by even 100 square feet, that's probably a few grand in your pocket. Plus, that cut subsequently reduces other related costs such as carpet, shipping, drayage, cleaning, etc."

Downsize your space. "The size of your booth space doesn't matter nearly as much as what you put in it," says Kimberly Kee, founder of Denver-based event company Kinetic Events (formerly Kee Consulting). "Downsize your booth size and ratchet up its effectiveness. After all, is there really much difference between, say, an 80-by-80 exhibit and a 50-by-50?" Brad Montgomery, CTSM, marketing and communications director at Accuform Signs in Brooksville, FL, agrees that even a little reduction in size can mean a big savings. "Your booth space is often the largest single-item expense in your show budget," he says. "So if you can reduce your booth space by even 100 square feet, that's probably a few grand in your pocket. Plus, that cut subsequently reduces other related costs such as carpet, shipping, drayage, cleaning, etc."

Switch to lighter-weight properties. "It sounds obvious, but by switching out our old heavy properties with lighter-weight ones, we expect to save $50,000 per year in storage, transportation, drayage, and installation and dismantle," says Janice Breuer, CTSM, trade show specialists with FFF Enterprises Inc. in Temecula, CA.

Switch to lighter-weight properties. "It sounds obvious, but by switching out our old heavy properties with lighter-weight ones, we expect to save $50,000 per year in storage, transportation, drayage, and installation and dismantle," says Janice Breuer, CTSM, trade show specialists with FFF Enterprises Inc. in Temecula, CA. Request pricing for multiple material options. Before you purchase your next exhibit, ask your suppliers to price out multiple material options in varying thicknesses, qualities, and prices, and to explain the pros and cons of each. Matt Daniels, project manager at Winntech, a Kansas City, MO-based retail, fixture, and merchandising-design firm, suggests that rather than automatically using Lexan, a popular brand of polycarbonate, for example, get pricing and information on multiple, perhaps generic, forms of polycarbonates. Or instead of using Plexiglas, investigate various acrylics. You might find that a cheaper, lesser-known material can still meet your needs.

Request pricing for multiple material options. Before you purchase your next exhibit, ask your suppliers to price out multiple material options in varying thicknesses, qualities, and prices, and to explain the pros and cons of each. Matt Daniels, project manager at Winntech, a Kansas City, MO-based retail, fixture, and merchandising-design firm, suggests that rather than automatically using Lexan, a popular brand of polycarbonate, for example, get pricing and information on multiple, perhaps generic, forms of polycarbonates. Or instead of using Plexiglas, investigate various acrylics. You might find that a cheaper, lesser-known material can still meet your needs.  Buy a used property. Second owners can save 50 to 75 percent off the cost of building new. Check sites such as ExhibitAuction.com, ExhibitorOnline.com, Exhibits.com, Used-Trade-Show-Booths.com, and Webisales.com, which offer used exhibits including everything from custom properties ready for refurbishing to blank-slate tabletops and pop-ups. Also ask your exhibit house and industry peers to stay on the lookout for any exhibitors looking to sell their used exhibit properties.

Buy a used property. Second owners can save 50 to 75 percent off the cost of building new. Check sites such as ExhibitAuction.com, ExhibitorOnline.com, Exhibits.com, Used-Trade-Show-Booths.com, and Webisales.com, which offer used exhibits including everything from custom properties ready for refurbishing to blank-slate tabletops and pop-ups. Also ask your exhibit house and industry peers to stay on the lookout for any exhibitors looking to sell their used exhibit properties. Pay on time. As you pay for your new exhibit and services, try to continually provide payment on or ahead of schedule, as timely payment may be cause for a discount. "Similar to many industries, exhibit-industry suppliers sometimes suffer cash-flow problems," says Matthew Green, founder of Project Profile Ltd., a London-based face-to-face communications agency. "If you consistently pay on time, you can often negotiate 'timely' discounts for anywhere from 10 to 30 percent off your typical fees." E. Jane Lorimer, managing director of Lorimer Consulting Group in Denver, also suggests that paying up front might actually cost you less than paying over time. For example, if you pay your entire space cost up front rather than paying it in installments, you have the opportunity to negotiate for a lower total cost. Bottom line, if your timeliness and organization pay dividends for your suppliers, it could mean a discount for you.

Pay on time. As you pay for your new exhibit and services, try to continually provide payment on or ahead of schedule, as timely payment may be cause for a discount. "Similar to many industries, exhibit-industry suppliers sometimes suffer cash-flow problems," says Matthew Green, founder of Project Profile Ltd., a London-based face-to-face communications agency. "If you consistently pay on time, you can often negotiate 'timely' discounts for anywhere from 10 to 30 percent off your typical fees." E. Jane Lorimer, managing director of Lorimer Consulting Group in Denver, also suggests that paying up front might actually cost you less than paying over time. For example, if you pay your entire space cost up front rather than paying it in installments, you have the opportunity to negotiate for a lower total cost. Bottom line, if your timeliness and organization pay dividends for your suppliers, it could mean a discount for you.

Consider rental exhibits. Given recent advancements in exhibit rental - including multi-use agreements, build-to-suit contracts, and custom/rental hybrid solutions - not to mention an almost industry-wide uptick in the quality of rental components over the last 15 years, renting can prove to be a viable and cost-effective solution. Not only does rental require a much smaller initial cash outlay, it also eliminates almost all costs of ownership, from storage and insurance costs to refurbishing and disposal fees. So before you buy, investigate not only the costs of rental but also the costs of ownership.

Consider rental exhibits. Given recent advancements in exhibit rental - including multi-use agreements, build-to-suit contracts, and custom/rental hybrid solutions - not to mention an almost industry-wide uptick in the quality of rental components over the last 15 years, renting can prove to be a viable and cost-effective solution. Not only does rental require a much smaller initial cash outlay, it also eliminates almost all costs of ownership, from storage and insurance costs to refurbishing and disposal fees. So before you buy, investigate not only the costs of rental but also the costs of ownership.

Select multipurpose elements. "If you're building a booth anyway, consider each element's potential use, not just in various booth configurations but also in non-trade-show functions, such as customer events, sales presentations, private demos, etc.," says Tony Castrigno, senior partner and CEO of Designcontact, a New York exhibit-design firm. "If you can extend the use of an element beyond the trade show to other marketing- or sales-related events, you can double its value."

Select multipurpose elements. "If you're building a booth anyway, consider each element's potential use, not just in various booth configurations but also in non-trade-show functions, such as customer events, sales presentations, private demos, etc.," says Tony Castrigno, senior partner and CEO of Designcontact, a New York exhibit-design firm. "If you can extend the use of an element beyond the trade show to other marketing- or sales-related events, you can double its value."

Reduce, reuse, repurpose. Rather than reinventing the wheel - or the graphic image - reuse artwork from current ad campaigns or other marketing efforts to cut costs on image creation and design. And don't limit your search for existing images to your department or office. Expand your search to other departments, divisions, and office locations within your company.

Reduce, reuse, repurpose. Rather than reinventing the wheel - or the graphic image - reuse artwork from current ad campaigns or other marketing efforts to cut costs on image creation and design. And don't limit your search for existing images to your department or office. Expand your search to other departments, divisions, and office locations within your company.

Consider stock photography. "If existing artwork isn't available, search low-cost stock-photography Web sites, rather than shooting the images yourself or buying stock shots from well-known, high-end sites such as Getty Images

Inc.," says Tim Provo, president of Elements Exhibits LLC in North Las Vegas, NV. "While Getty provides literally a million fabulous shots, lesser-known stock-photography sites such as iStockphoto.com can provide similar images at a fraction of the cost. Shopping around can mean the difference between a $300 image and a near-identical shot available for $10."

Consider stock photography. "If existing artwork isn't available, search low-cost stock-photography Web sites, rather than shooting the images yourself or buying stock shots from well-known, high-end sites such as Getty Images

Inc.," says Tim Provo, president of Elements Exhibits LLC in North Las Vegas, NV. "While Getty provides literally a million fabulous shots, lesser-known stock-photography sites such as iStockphoto.com can provide similar images at a fraction of the cost. Shopping around can mean the difference between a $300 image and a near-identical shot available for $10."  Look outside the industry. "When it's time to buy new graphics for my banner stands, I use a local advertising/sign shop to create replacements, rather than purchasing