|

REGISTRATION REQUIRED

case study

DIY I&D

After company management insists she bring installation supervision in-house, marketing coordinator Trina Schiavitti crafts a DIY manual that simplifies the process and cuts I&D costs by thousands of dollars each year. By Linda Armstrong

Schiavitti's plucky solution was born of an internal challenge set down by management at Zehnder Rittling, a manufacturer of heating, cooling, and ventilation products for industrial and commercial properties. It all started roughly a year into her tenure at the firm, where she took on the responsibility of managing a show for the first time in her career. One of her primary tasks was overseeing the company's 20-by-40-foot exhibit at the International Air-Conditioning, Heating, Refrigerating Exposition (AHR), the only national show at which the firm exhibited and the only trade fair on Schiavitti's to-do list. Shortly after her first AHR, her boss explained that in an effort to cut costs, they would eliminate the I&D supervisor altogether and transfer exhibit storage to the Zehnder Rittling warehouse. He insisted she learn all she could during her second AHR because by year three she would be wrangling I&D on her own. Mind blown. Bombshell dropped. Thankfully, Schiavitti had been an eager and attentive learner during her first AHR, as she'd taken copious notes about setup and photos of the process, and she'd shadowed the existing I&D supervisor throughout the experience. In fact, she, like her boss, had already discerned that setup was complex, costly, and time consuming. The booth might have gone up and come down in the allotted time, but she felt a massive amount of energy had been wasted – and she had already assembled a list of potential improvements. So when her boss challenged her to take over the entire process, she was both overwhelmed by the daunting task in front of her and energized at the prospect of improving the experience. Setup Setbacks Straight out the gate, Schiavitti knew she'd need to create her own installation manual to guide setup. Since the booth was only erected once per year, she'd need a written handbook to jog her memory. However, if she was going to wrestle this beast, she wanted to tame it a bit first. Thus, before formally crafting the manual, she carefully analyzed the time-consuming trouble spots that plagued the current I&D process. Almost immediately, her scrutiny landed on the exhibit's flooring system. The base consisted of an elevated platform made of 2-by-2-foot panels, which was then topped with padding and a vinyl product that resembled hardwood planks. But each panel had four adjustable pegs that screwed into its corners, and the literally hundreds of pegs in the system had to be set at the same height, otherwise the floor became an uneven – not to mention unsafe and unsightly – mess. "Our labor crew had to insert and adjust hundreds of pegs to get the system up and then go back and readjust any that weren't uniform," Schiavitti says. "Flooring installation took forever." Another I&D time suck involved the 120 pieces of aluminum extrusion that comprised the exhibit's frame and the 17 infills that were inserted between the extrusions to form walls. "Somehow during the new-build process for our booth, we ended up with an extrusion product that used the metric system and whose engineers were, shall we say, organizationally challenged," she says. This meant that installation schematics and extrusion labels used figures such as 88.582 inches and 255.906 inches, which represented 2.5 and 6.5 meters, respectively.

One of Trina Schiavitti's top priorities was to find a way to organize and label her exhibit's 120 aluminum extrusions, which had to be installed in a specific order.

What's more, connectors on the ends of the extrusions were specific to their intended locations. "Even if you searched through all 120 pieces and located one that was the right length," Schiavitti says, "it might have had the wrong type of connector on the end, forcing you to relaunch your search for another 255.906-inch bar with the right doohickey attached." Product positioning and graphics were also sticky wickets. The system used laminated graphics that were mounted on Plexiglas. The resulting panels – some double sided and some single sided – slid into grooves in the extrusions. However, if crewmembers didn't insert the graphics at the right time in the installation process, they often had to disassemble an entire section or an attached header to remedy the situation. The same fate awaited setup laborers that inserted a graphic in an incorrect place or somehow reversed the graphic so the wrong side was facing out. This problem was compounded by the fact that most products didn't have a permanent home within the exhibit, and they were often placed in the display after most of the extrusion and graphic-panel assemblies had been completed. So in some cases the graphics didn't match the products displayed near them, or large-scale products blocked the graphics entirely – an issue typically caused by a one-sided graphic facing the wrong way. Bottom line: Installing graphics and placing products was like working a jigsaw puzzle. Crewmembers had to continually reposition both to ensure they were visible and presented a logical message to booth visitors. Foundational Fixes As her second AHR neared, Schiavitti began assembling a rough draft of her manual, gathering the photos, notes, and sketches she'd collected the first year into an electronic format so she could add additional info from the upcoming show. However, given the pitfalls she'd uncovered, she set her sights on fixing a few of the issues before the next show even opened. To that end, she devised a solution for the flooring system and its dreadful pegs. "I worked with some of our shop employees to come up with a wooden height-adjustment guide for the pegs," Schiavitti says. "As you installed each peg, you simply lined it up with the guide, which then ensured that all of the pegs were set to the same height." She planned to make the guide available to the crew at the next AHR, but when her exhibit moved to Zehnder Rittling for storage, she'd use the guide to install and set all of the pegs into the flooring system prior to the show. That way when laborers assembled the system on site, they could simply use the guide to verify that the pegs hadn't moved in transit and then snap the flooring panels quickly into place. Next, she brainstormed ways to transform the needle-in-a-haystack extrusion hunt into an organized procedure – and to somehow manage the metric-system mayhem. Ultimately, she created an entirely new labeling system arranged according to setup chronology as well as vertical versus horizontal positioning. Each extrusion's wacky meters-to-inches-based label would be replaced by a number, with No. 1 being the first extrusion installed and 120 being the last. Each number would also be accompanied by an H or a V (horizontal or vertical) to note the element's positioning, and the labels would be either red (horizontal pieces) or blue (vertical pieces). Each of these numbered and color-coded labels would have a preceding number corresponding to the section of the exhibit in which it was installed. For example, after the flooring, the first exhibit component to go up was the closet, which also comprised some aisle and side walls. So all of the 15 extrusions required to construct this element would have a No. 1 in front of them (e.g., 1-1 H, 1-2 H, 1-3 V, etc.). Meanwhile, infills and graphics (17 total) would receive letter identifiers (A, B, C, etc.).

With a new organizational plan in place, she headed off to AHR to dive even deeper into I&D, as she'd be flying solo the next time around. Throughout most of setup, Schiavitti took detailed notes and photos and asked literally hundreds of questions.

When the work was finished, she then shot photos of everything, visually documenting which type of extrusion connectors were used where, how a particularly tricky overhead fabric header was constructed, and where each graphic, infill, and product was placed within the exhibit. Dismantle Details Once the show was over and teardown began in earnest, Schiavitti started implementing her newly developed labeling system. "I labeled each piece of extrusion according to its chronological position within the teardown process," she says. "So the first piece that came down was labeled No. 120, and it went into the bottom of the crate. The next pieces were Nos. 119, 118, 117, and so on." She couldn't completely reorganize the crates at the show because of the preinstalled crate bumpers, but by the time she and her booth reached the Zehnder Rittling warehouse, all of the extrusions were properly labeled, albeit temporarily, according to the new system. Back at the office, where her exhibit had now taken up permanent residence, she began the arduous reorganization process by removing the contents of all 16 crates. Schiavitti then literally crawled inside each one to remove its previously installed bumpers, padding, etc. Next, she reorganized and repacked all of the components based on her chronological setup process, and she reinstalled the padding as necessary. Schiavitti also carefully labeled and photographed the crates throughout her work in progress so she could add further visuals and documentation to the manual that would help aid workers when packing and unpacking the crates at future shows. During the crate-reorganization process, she attached both permanent and temporary labels to the extrusions. She printed the various color-coded and numbered labels on card stock and cut them to a size that would fit inside the hollow extrusions. Using a piece of clear packing tape to cover and attach the labels, she placed one inside each end of every extrusion. By placing the tape over the entire face of the label, Schiavitti also provided a decent level of protection against wear and tear.

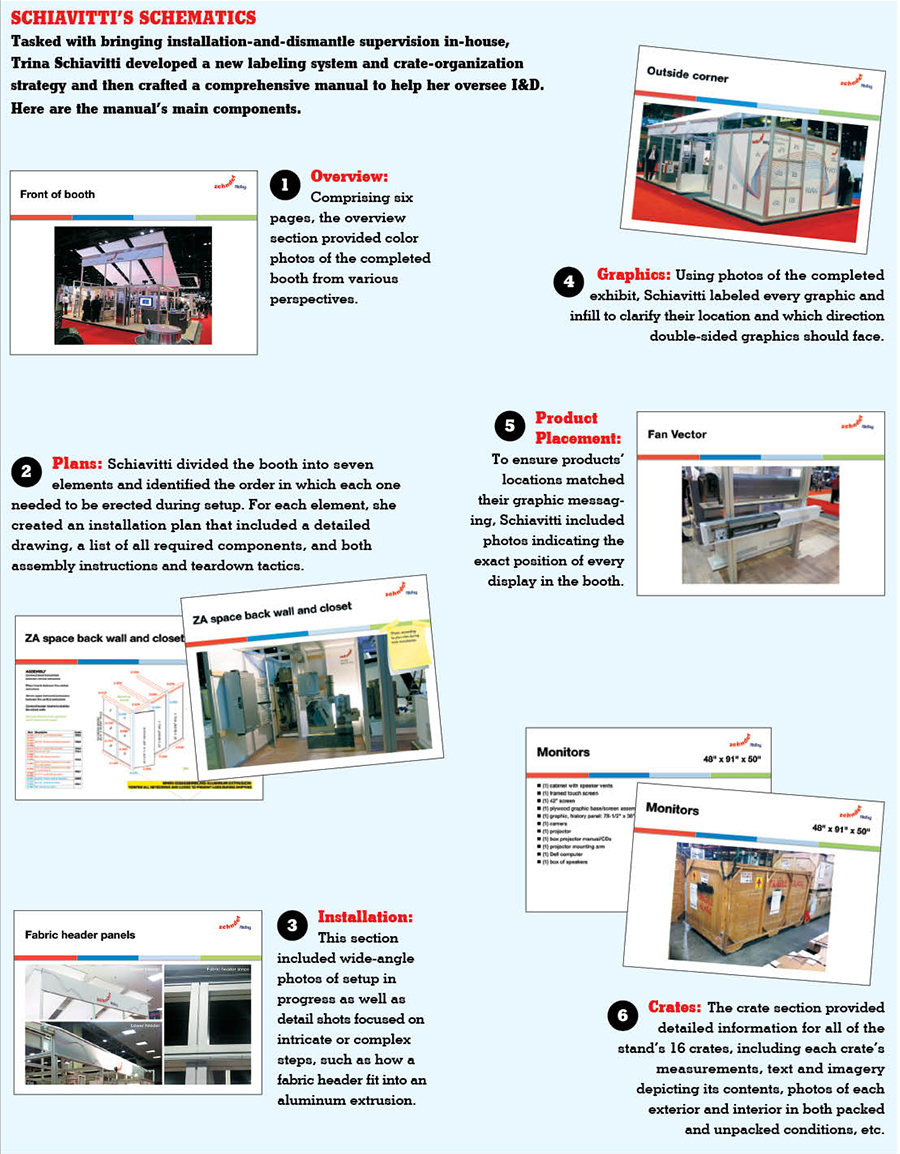

DO TRY THIS AT HOME

With the permanent labels in place, she fashioned a set of temporary labels. But this time, she attached them to the extrusions with painter's tape, which leaves no residue when removed. "Although there were permanent labels inside each extrusion, they weren't highly visible, especially while in a crate on the show floor," she says. "But you could see the temporary labels on the exterior of the pieces from 10 paces." So for the first show, the extrusions would arrive with both permanent and temporary labels in place. The setup crew would remove and discard the temps, and just before teardown, Schiavitti would attach a new set of exterior labels that she'd brought with her. "It made the extrusions easier to spot, making packing and unpacking much more simple than peeking in the end of each piece every time."Trina Schiavitti, former marketing coordinator at Zehnder Rittling, is the first to admit that crafting an installation-and-dismantle manual and supervising your own I&D isn't easy – and it's probably not for everyone. However, she offers the following been-there-done-that advice if you want to give it a shot. Ensure you're the right person for the job – as opposed to someone else on your team. "Whoever takes on this task must be detail oriented, possess the ability to grasp step-by-step processes, and tactfully manage an on-site crew," she says. "If that's not you, don't force it. Look for someone on your team that can fill this role instead." Assess existing organizational strategies from the ground up. Before you attempt to write your own manual, analyze the organization components already in place (e.g., labels, installation order, crating organization, etc.) to ensure they make sense. If something needs tweaking, address it first so your manual has a solid footing. Initiate and foster industry relationships. "Even though I now work in an entirely different industry, I still keep in touch with my contacts at show management and the exhibit house," Schiavitti says. Everyone from your exhibit-house rep to the men and women running around in carts at the show can help you understand your booth, the industry, and the overall installation and teardown process. Plus, any one of these can be a godsend if something goes haywire. Radical Renovations As Schiavitti's physical reorganization continued, she simultaneously compiled what ultimately became a 116-page installation manual, organized into six sections. The first was a broad overview that provided numerous photos of the completed booth. The next section offered a plan for each of the booth's seven primary elements. Each plan featured a detailed drawing of the exhibit element with every extrusion and infill labeled according to Schiavitti's new system. A table to the left of the drawing listed all of the extrusions necessary for this element along with the crate number in which they were located. Brief yet adequate step-by-step assembly instructions appeared in the top left, and any special teardown tips were provided in the lower right (e.g., "Tighten all setscrews and locks to prevent loss during shipping.") Schiavitti included labeled photos of the completed elements throughout the plans to further aid installation. Comprising mostly overview photos and detail shots, the installation section of the manual further illustrated tricky parts of the setup process. The graphics section that followed provided photos of the completed exhibit, but all graphics and infills were clearly labeled according to her new lettering system. Similarly, the product-placement section offered images of all of the displays within the completed exhibit so there would be no question as to their location in relation to the graphics. Finally, the last section outlined the contents and measurements of the exhibit's 16 crates and featured photos of each container packed and unpacked. To complete this section, however, she reorganized the crates according to setup and teardown chronology. So crate No. 1 housed all of the equipment, hardware, tools, and extrusions necessary for the first step of setup. Crate No. 2 housed the next set of pieces, and so on. She also organized the extrusions so that the first pieces removed would also be the first pieces required for that particular phase of setup.

By eliminating the exhibit house's I&D supervisor, the firm continues to pocket an estimated $4,100 in savings at AHR each year, and by storing the exhibit in its own warehouse, it saves an additional $2,200 in storage fees annually. When you add in associated costs to pull and prep the booth prior to the show and factor in the previous fees for a considerably longer setup time (which typically involved four crew members for 2.5 days on average), Schiavitti estimates that her efforts save the company an average of more than $12,600 each year.

Trina Schiavitti estimates her efforts to supervise and streamline the I&D process have saved Zehnder Rittling an average of more than $12,600 each year.

"While I&D seemed unnerving at first, I absolutely loved managing and participating in the process," Schiavitti says. "I loved triaging unexpected snafus as they arose and really being involved in the nitty-gritty of exhibiting." And while she realizes that not all exhibitors are willing or able to bring I&D supervision and storage in-house, she suggests everyone at least consider taking a deep dive into the process. Even if you don't actually manage setup, the knowledge you'll gain by taking the time to fully understand it – including everything from chronology and assembly to packing and crate organization – will allow you to make more confident and effective decisions about your program. "The process I went through was daunting. It was hard work. It was kind of like birthing an elephant," Schiavitti says. "But it gave me the confidence and earned me the respect I needed to complete the task at hand and ultimately to move on to a new endeavor." E

|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

TOPICS Measurement & Budgeting Planning & Execution Marketing & Promotion Events & Venues Personal & Career Exhibits & Experiences International Exhibiting Resources for Rookies Research & Resources |

MAGAZINE Subscribe Today! Renew Subscription Update Address Digital Downloads Newsletters Advertise |

FIND IT Exhibit Producers Products & Services All Companies Get Listed |

EXHIBITORLIVE Sessions Exhibit Hall Exhibit at the Show Registration |

ETRAK Sessions Certification F.A.Q. Registration |

EDUCATION WEEK Overview Sessions Hotel Registration |

CERTIFICATION The Program Steps to Certification Faculty and Staff Enroll in CTSM Submit Quiz Answers My CTSM |

AWARDS Exhibit Design Awards Portable/Modular Awards Corporate Event Awards Centers of Excellence |

NEWS Associations/Press Awards Company News International New Products People Shows & Events Venues & Destinations EXHIBITOR News |

||||||||||||||||||||

|

||||||||||||||||||||||||||||