|

REGISTRATION REQUIRED

exhibiting 101

Material World

Keep drayage fees from draining your budget by following these cost-cutting tips.

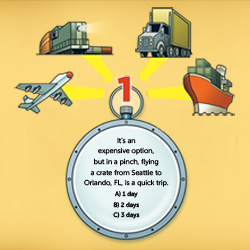

Any time exhibitors talk about their shrinking budgets and escalating expenses, material-handling (aka drayage) costs will invariably make it into the discussion. So how are material-handling fees calculated, why are they so darned expensive, and what are ways to prevent them from taking a massive bite out of your bottom line? Here's a quick explanation and a handful of down-and-dirty cost-cutting tips.

Calculating Drayage Drayage is billed to exhibitors by the hundredweight (CWT) of freight for the round-trip services provided by the general service contractor (GSC), who is the exclusive provider of all material-handling services. Your carrier will weigh your shipment (subtracting the weight of the trailer with and without your freight to determine the freight's net weight) and purchase a certified weight slip attesting to this official weight. To compute drayage costs, this weight is usually rounded up to the next hundred, so 301 pounds would be calculated as 4 CWT. However, some GSCs will give you a few pounds of leeway before rounding up. The rate you're charged for material handling is based on seven factors, including where the freight is being delivered (advance warehouse versus show site), whether it's delivered within the time frames specified in the exhibitor services manual, the weight noted on the certified weight slip(s) of all your inbound freight with a minimum weight per shipment (usually 2 to 3 CWT), the type of transportation carrier delivering it (common versus specialized carrier), the kind of freight being unloaded (crated, mixed, or blanket-wrapped) and the percentage of each type, whether special handling applies, and if your shipment is handled on overtime. But even with those factors in mind, it's still hard to wrap our minds around the high cost of drayage. So what other factors are at play when it comes to calculating material-handling costs? Exhibitors rarely think about the planning involved with moving thousands of pounds of freight long before the show begins. Those expenses include renting marshaling-yard space near convention halls and hotels, placing equipment such as mobile offices and portable scales in the marshaling yard, paying staff to direct the material-handling process from the marshaling yard to the docks, operating equipment such as forklifts and dollies, paying Teamster labor to check in the shipments as they arrive, processing the billing paperwork, and supervising freight delivery. And don't forget the personnel at the GSC's service desk who'll be inputting all your drayage information to generate your final invoice and distributing the empty labels that improve the end-of-show return of boxes, cases, crates, and pallets. Then there are uniform material handling agreements to distribute as exhibitors sign off on their GSC invoices that allow the GSC to relinquish exhibitors' freight to the designated carriers. Clearly, there are more players and steps involved than simply schlepping your freight from your truck to your booth space and back, although GSCs admit that material handling is a major moneymaker. If you don't think that list adequately justifies the material-handling rates that exhibitors are being charged, you may be right. In addition to the transparent costs listed here, some show managers request that the GSC roll other show-related costs into exhibitors' material-handling fees by using cost-shifting to create a "zero invoice" for the show manager or organizer (essentially divvying up all the infrastructural expenses of hosting an event among the exhibiting companies via revenue generated by their drayage bills). These extras can include products and services needed for the overall show, such as the production and hanging of aisle signage, aisle carpeting and the labor to lay it on the show floor, attendee and exhibitor registration counters, informational and directional signage, and the furnishing of common areas. Cutting Costs Now that you know what drayage fees are based on, here are some of my top tips for proactively mitigating material-handling costs. ➤ Know how your exhibit will be packed. Ask your exhibit house if your shipment qualifies as totally crated/palletized freight. If you have any loose or pad-wrapped exhibit properties that will throw your shipment into a more expensive material-handling category, strapping them to the top of a crate or palletizing them changes the classification to crated/palletized, which can mean significant savings. ➤ Make use of material-handling package deals. Some show organizers negotiate to have the GSC create packages combining drayage and other ancillary services it provides. These packages can include no-cost freight handling of a certain number of pounds per square foot of booth space without additional drayage fees. Other GSCs allow drayage discounts if you are using them as your shipping carrier. But don't assume that you're saving money by using the official carrier. Get a competitive bid from a similar carrier that's not sharing profits with the GSC, and add the nondiscounted material-handling costs quoted in the exhibitor services manual. Also note that exhibit furniture and audiovisual equipment rented through the GSC or official contractors do not generate material-handling fees, so to compare apples to apples, you need to add drayage fees to any nonofficial vendor's quote. ➤ Opt for lightweight exhibitry. Examine your exhibit and past drayage bills. Is your exhibit heavy and bulky to ship and move to the show floor? If so, make one of the criteria in your next request for proposal (RFP) the use of lighter materials for both the exhibit and its crating. ➤ Minimize collateral literature and promotional items. It's estimated that 80 percent of collateral on the show floor never makes it back to attendees' offices but instead ends up in the trash. To cut costs, you can print inexpensive business cards, include a URL that takes visitors to a website with information about the products you're featuring at the show, add a toll-free phone number, and list your key messages on the back. ➤ Choose the right carrier. Material-handling costs are based on how trucks are loaded and the labor and equipment it takes to unload and reload them. If you ship via a common carrier that floor loads your crated or palletized freight rather than stacks it vertically, you'll get the best drayage rate since it's quick and easy to move with a forklift. Every other type of carrier that stacks freight, handles blanket wrap or small packages, and mixes small loads of freight is considered a specialty carrier, and you will be charged a higher drayage rate (usually 30 to 40 percent) for these shipments due to the additional labor, time, and equipment required. Even though there is a difference in material-handling costs depending on the type of carrier, your selection should be based on the level of service you require. Work with your carrier to make sure your driver is informed of your assigned check-in window at the marshaling yard so he or she can help you avoid off-target penalties, overtime charges by the GSC, and detention fees by the carrier. ➤ Consolidate small shipments. One of the biggest budget breakers is shipping small packages through the show docks, as the GSC may weigh them at its minimum of 2 to 3 CWT.For example, if you use a small-package carrier such as FedEx or UPS, be aware that these shipments do not provide a separate bill of lading required for drayage processing. The result? This freight's delivery to your booth space will be delayed until the proper paperwork can be generated on the dock. Also, multipiece shipments (i.e., those just marked "1 of 2" and "2 of 2" that aren't bound together) might not be processed on the dock at the same time, causing you to pay multiple material-handling minimums that increase your drayage bill. If possible, either band together like-sized cartons, pack smaller boxes in one large carton to avoid incurring multiple minimum-weight charges, or ship small packages to your hotel and bring them to the venue yourself. ➤ Verify your certified weight. I have encountered many weight-slip errors that caused inflated material-handling charges. In one instance, my 4,040-pound shipment was recorded as 10,000 pounds because the forklift driver didn't clear the weight of the prior exhibitor's freight from the built-in scale. If something seems off, it warrants a second look.➤ Audit your material-handling invoice. It's imperative to audit every line of your material-handling invoice while on site for charges you don't understand or recognize. Through the years, I've been charged all kinds of bogus fees. I was once charged marshaling-yard fees for freight that was delivered by a small-package carrier that had its own dock for deliveries and didn't even go to the marshaling yard. And I've been billed for unloading freight that belonged to an exhibitor with a similar company name. In most cases, a discussion with service-desk personnel while I was still on site resulted in the removal of these erroneous charges. Once everyone leaves the show city, it's very difficult – if not impossible – to correct these mistakes. Finally, don't hesitate to communicate to show management your displeasure with the rising costs of drayage. Because as long as show managers think exhibitors aren't privy to their cost-shifting tactics, they'll continue to pad our drayage bills. As exhibitors, we need to proactively control the costs and fees we can, but we also need show management's help in holding the line. E  Candy Adams

Candy AdamsCTSM, CEM, CMP, CMM "The Booth Mom," is an independent exhibit project manager, trainer, speaker, consultant, and an Exhibitor Conference faculty member. CandyAdams@BoothMom.com

|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

TOPICS Measurement & Budgeting Planning & Execution Marketing & Promotion Events & Venues Personal & Career Exhibits & Experiences International Exhibiting Resources for Rookies Research & Resources |

MAGAZINE Subscribe Today! Renew Subscription Update Address Digital Downloads Newsletters Advertise |

FIND IT Exhibit Producers Products & Services All Companies Get Listed |

EXHIBITORLIVE Sessions Exhibit Hall Exhibit at the Show Registration |

ETRAK Sessions Certification F.A.Q. Registration |

EDUCATION WEEK Overview Sessions Hotel Registration |

CERTIFICATION The Program Steps to Certification Faculty and Staff Enroll in CTSM Submit Quiz Answers My CTSM |

AWARDS Exhibit Design Awards Portable/Modular Awards Corporate Event Awards Centers of Excellence |

NEWS Associations/Press Awards Company News International New Products People Shows & Events Venues & Destinations EXHIBITOR News |

||||||||||||||||||||

|

||||||||||||||||||||||||||||