|

REGISTRATION REQUIRED

exhibiting 101

The Ins and Outs of I&D

Ensure your exhibit goes up and comes down without a cringe-worthy catastrophe by following these installation-and-dismantle tips.

Looking back at all of the show-floor surprises I've had with installation and dismantle, it's undoubtedly when I feel the most professionally vulnerable. I can control the many pre-show elements of an exhibiting program, but those best-laid plans can quickly become sidelined by amateurish I&D labor crews, absent-minded general services contractors (GSCs), etc. The best advice I can give any rookie exhibit manager is to do whatever you can as early as you can. And even when you think you've built in sufficient time to get everything done, there can still be an unexpected snafu just waiting to trip you up. So in addition to not leaving for tomorrow what can be done today, here is some sage advice to consider when it comes to successful exhibit setups and teardowns.

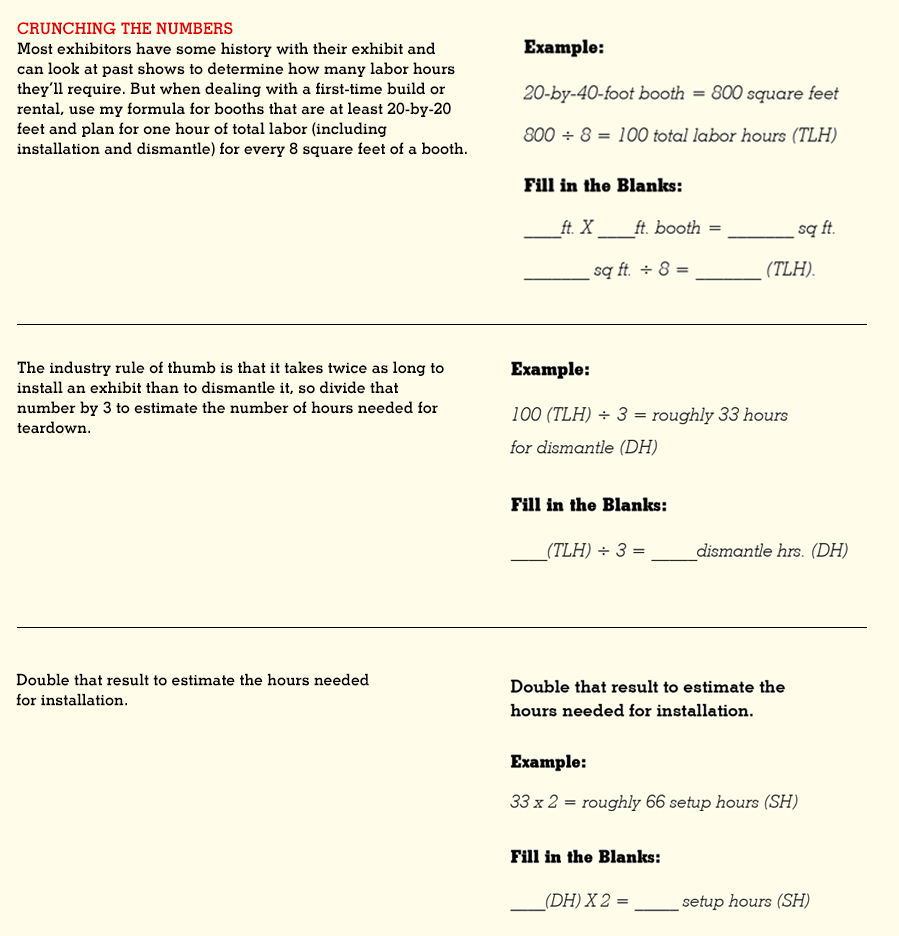

Start at the Drawing Board I&D planning should begin when your exhibit is being designed. To minimize labor hours, work with your exhibit house to identify the time hogs that eat up your on-site labor hours. Tasks such as intricate assembly of displays or graphic applications will generally be more cost effective (and take less time) when done in the exhibit house's shop rather than on the show floor. The more show ready you can make your stand when it's in the hands of your exhibit house, the smaller your margin of labor-crew errors will be at the show. For example, I have vinyl graphics applied at the exhibit house rather than at the venue because: 1) the warehouse is cleaner than the show floor, 2) the graphic staff is generally more meticulous, 3) the labor at the exhibit house is typically cheaper than an on-site I&D crew, and 4) if there's a problem, it can be nipped in the bud before the exhibit ships to the show venue. I also ask for the exhibit house to install the brackets that hold any hanging monitors, or at least to measure and drill the holes for these brackets. For one trade show, we designed the demonstration kiosks to simply slide out of their crates with the majority of the assembly (such as monitor brackets and recessed lighting) already in place. Even though this pre-assembled freight might take up more shipping space dimensionally, it can result in significant labor-cost savings on the show floor. Catch Problems Before They Arise I'm a big fan of arriving at the show floor a day early to get the lay of the land. This is also a good opportunity to verify the installation and correct placement of any under-carpet services such as electrical and internet. I once arrived on show site to find my 20-by-30-foot booth space was marked as a 20-by-40-foot space, and all the electrical outlets were in the wrong location. I've also had my electrical rotated 180 degrees from where it should have been, and another time I had no utilities because my confirmed orders had been misplaced. Thus, I always try to make it to the venue a day earlier than I have to be there, which allows enough time to solve problems before my labor crew arrives for setup. Roll up Your Sleeves In most exhibitor services manuals, you will find a page under the section on union labor that explains the jurisdictions of the various unions in place at the convention venue. Common union-only functions include moving freight on anything that has four wheels (e.g., forklifts or dollies), laying electrical wiring under carpet, rigging signs and banners, and assembling exhibits that require tools. In most venues, you are allowed to circumvent the docks by hand carrying in some freight, and an exhibiting company's full-time employees can usually install and dismantle an exhibit in a 10-by-10-foot booth space provided it can be constructed in 30 minutes or less with no hand tools or ladders. When in doubt about what can be accomplished without hiring union labor, your best bet is to talk with the show's operations manager. Watch the Clock To minimize your I&D invoice, think "straight time" rather than "overtime" or "double time" whenever possible. Union contracts have all kinds of clauses regarding what constitutes straight time versus double time, overtime, or holiday pay. Sometimes union contracts even allow a holiday that falls on a weekend – such as Veterans Day – to move to a Monday, turning what would have been a straight-time day into a budget buster. Also, most labor contractors only guarantee the start time of your labor crew if you order an 8 a.m. start. If your freight's scheduled to unload between 8 a.m. and noon and you order your labor for 12:30 p.m. after the union's lunch hour, it is considered a "will call" labor order. That means you'll have to wait until those laborers have finished their morning job (which probably took longer than everyone expected) before they finally show up at your booth. Labor costs will likely comprise a large chunk of your I&D invoice, so it's important to learn the following ways to avoid overtime hours. ➤ Ship exhibit freight to the advance warehouse so it arrives on the trade show floor earlier, thus providing more straight-time setup hours. Alternatively, you can just send the exhibit's carpet pad, carpet, Visqueen, and carpet tape to the advance warehouse, and then ship the rest of your exhibit properties direct to site. This allows enough time for workers to install flooring before your exhibit is ready to be constructed.➤ Rent carpet from the GSC that will be laid on straight time as part of the carpet-rental cost, negating the need to purchase or rent carpet from an outside vendor. This also eliminates shipping costs, material-handling fees, and on-site overtime labor. ➤ Hire additional installation laborers at the beginning of the day and drop some of the less productive workers as the setup progresses and you have a clearer idea of your time frame. ➤ Dismantle your booth the morning after the show, as the labor may be on straight time rather than costly evening overtime. Choose Your Labor Team Wisely There are various experience levels from "still learning" apprentices to "been there, done that" journeymen who work at different pay rates within the union, and it financially benefits GSCs and exhibitor-appointed contractors (EACs) to hire the least-skilled (and lowest-paid) laborer who can do the job. In cities with shallow labor pools, this could mean your crew comprises anyone from people hired through temporary agencies to people who responded to a labor call on the street behind the convention center for a day's cash wages. But you may have noticed that both GSCs and EACs publish one flat hourly rate (often referred to as the "city rate" for that location) for straight time, overtime, and double time (if double time is part of that local's union contract), regardless of the skill level – or pay rate – of the person you're assigned. While GSCs offer labor by the hour, most EACs providing I&D labor offer full-service packages that include planning to alleviate on-site gotchas, big-picture views of the entire project (plus supervision), hand-picked labor, and supplies. I also find that EACs are more willing to waive the four-hour union-labor minimum when my setup only takes an hour. That said, it can make sense to use the GSC if you rent exhibit properties from it, know you'll have last-minute changes on site, and/or need variances granted. Keep Everyone in the Loop Every show-service order form, set of instructions, and supporting drawing needs to be in the hands of the labor provider, especially if you're not going to be on the show floor during I&D. I also like to provide a copy of the setup plan marked for dismantle with each piece of the exhibit property labeled as to which crate it resides in to simplify teardown. If you are going to be present, talk with your crew lead and set the parameters for your role. Are you a hands-on manager who wants to lead an all-team meeting and point out the location of the next panel to install, or someone who will only get involved if asked to fetch the empty labels from the service desk? Making sure you and your crew lead are on the same page regarding your mutual expectations will avoid either party feeling like their toes are being deliberately stepped on. Also share with your labor crew the inventory and location of any supplies that have been shipped to the show. These may include a spare sheet or two of exhibit laminate; tape for your pad, carpet, and return shipping; Visqueen to protect your carpet during setup; rolls of hook-and-loop fastener for hanging graphics; extra light bulbs; stretch wrap and banding; touch-up paint; and nonstreak/nonstatic cleaning supplies. By having all the exhibit-setup supplies ready, laborers won't have to go search for them on your dime. It's also important to provide your lead with a set of the keys and combinations to your gang box, counters, kiosks, and closets. Close up Shop The show's over and the pressure's off, but now you have to get everything packed up and shipped out. And there's still plenty of time for something to go disastrously wrong. So to avoid any dismantle dysfunction, follow these steps. ➤ Plan your entire show cycle of I&D and order all of the show services that you will need at the same time so nothing is missed. ➤ At the end of your installation, confirm the day, time, and number of dismantle crew members with your labor contractor. Be sure to request any exceptional crew members you'd like to come back for dismantle by name, since they know how your exhibit came out of the crates and have a better shot at repacking it correctly. ➤ Make copies of what I refer to as "reverse blueprints," which show the crate or pallet number and/or location where each exhibit panel, door, kiosk, etc. is to be placed for return shipping. Compare the shipping manifest to the setup prints, or in lieu of that, have your exhibit house print photos of the loaded crates and attach them inside the crates for easy viewing. Anything you can do to streamline dismantle will decrease your labor ticket's bottom line. ➤ Have your outbound shipping documentation in hand and ready to turn in as soon as dismantle is complete. This includes the material handling agreement (MHA), which is your contract with the GSC that authorizes it to move your freight from your booth space and release it to your designated carrier, and a bill of lading (B/L), which is your contract with your carrier. Your truck driver will not be called to the docks to load your exhibit properties until this documentation has been turned in at the GSC's exhibitor service desk. I&D is my favorite part of the job and where the "rubber meets the road" after months of planning. By heeding the aforementioned advice, I&D can be an exciting (and sometimes challenging) way to use your creative problem-solving skills – and hopefully thwart Murphy's Law's best efforts to sink you. E

Candy Adams

Candy AdamsCTSM, CEM, CMP, CMM "The Booth Mom," is an independent exhibit project manager, trainer, speaker, consultant, and an Exhibitor Conference faculty member. CandyAdams@BoothMom.com

|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

TOPICS Measurement & Budgeting Planning & Execution Marketing & Promotion Events & Venues Personal & Career Exhibits & Experiences International Exhibiting Resources for Rookies Research & Resources |

MAGAZINE Subscribe Today! Renew Subscription Update Address Digital Downloads Newsletters Advertise |

FIND IT Exhibit Producers Products & Services All Companies Get Listed |

EXHIBITORLIVE Sessions Exhibit Hall Exhibit at the Show Registration |

ETRAK Sessions Certification F.A.Q. Registration |

EDUCATION WEEK Overview Sessions Hotel Registration |

CERTIFICATION The Program Steps to Certification Faculty and Staff Enroll in CTSM Submit Quiz Answers My CTSM |

AWARDS Exhibit Design Awards Portable/Modular Awards Corporate Event Awards Centers of Excellence |

NEWS Associations/Press Awards Company News International New Products People Shows & Events Venues & Destinations EXHIBITOR News |

||||||||||||||||||||

|

||||||||||||||||||||||||||||