The Guitar Hero

For a company that creates custom industrial-automation solutions, you'd think that setting up an in-booth robot demo would be as easy as greasing a gear. But when our automated attendee gatherer hit a glitch at the 2009 Medical Design & Manufacturing Minneapolis show, it took quick thinking and some engineering wizardry to get our robot once again clicking

on all pneumatic cylinders. For a company that creates custom industrial-automation solutions, you'd think that setting up an in-booth robot demo would be as easy as greasing a gear. But when our automated attendee gatherer hit a glitch at the 2009 Medical Design & Manufacturing Minneapolis show, it took quick thinking and some engineering wizardry to get our robot once again clicking

on all pneumatic cylinders.

Going into the show, we knew that a handful of other exhibitors also made automation solutions, and many of them had used simple robotic demos in the past. Thus, just programming a robotic arm to move marbles on a Chinese checkers board or pick up pieces of candy seemed like a been-there-done-that solution. So my co-workers and I needed to come up with a product demo that would not only show our capabilities and set us apart from the competition, but also get attendees to stop and chat with our staff. Fortunately, inspiration struck in plenty of time for the show - but in the most unlikely way.

Several of our engineers graduated from Alexandria Technical College in Alexandria, MN, where some current students had built a basic robotic device to play the video game "Guitar Hero." Their robot was able to shred some awesome riffs, earning perfect scores for the song they'd chosen, and it even used components we'd donated to the college for other projects. The riffin' robot was so innovative that students had made a video of this metal rock 'n' roller, and it was zipping its way around the engineering alumni right about the time we started searching for our killer product demo.

After hearing about the video from one of our engineers, my co-workers and I watched it and agreed: The automated guitar player seemed like a great traffic builder/product demo for our booth. It was fun. It utilized a game everyone had heard of. And since the viral video was such a big hit, chances were good that if we built a similar robot for our booth, our automated Jimi Hendrix would be a big hit on the show floor as well.

Not wanting to completely reinvent the wheel, we asked the students if we could borrow their metal rocker to use at our show. They were more than happy to lend it to us along with their gaming console and its faux guitar. But when the automated robot arrived at our offices, we discovered a problem. After carefully inspecting the robot, our team decided that too many of its parts were made by other manufacturers. We concluded that we wanted a robot built entirely out of our own components so we wouldn't run the risk of displaying our competitors' offerings in our booth. Plus, the students' robot was made rather crudely, and we felt we could improve upon the design, making our guitar player both look and perform better than the original.

While we used the students' Nintendo Wii and their copy of "Guitar Hero," we re-engineered the metal musician to meet our specs and use our parts. We built a box frame that would hold the guitar in place. Then we lined up pneumatic cylinders that were controlled by an electronic eye that watched the monitor for the notes to be played. When the eye saw the guitar notes moving across the monitor, it sent signals to the appropriate cylinder to push the corresponding button on the guitar's neck.

In the end, we had the perfect guitar god to attract attendees and show them how our devices really worked. We tested our creation before the show to make sure there weren't any unexpected notes in our melody, and sure enough, it worked flawlessly every time.

When the show opened in Minneapolis, we had our guitar player set up right on the aisle. Playing its song over and over, it never missed a note for the first few hours of the show. Crowds hovered around our booth watching the performance, while our booth staff talked to attendees about how the robot's awesome score on the game could translate to perfection on their production lines.

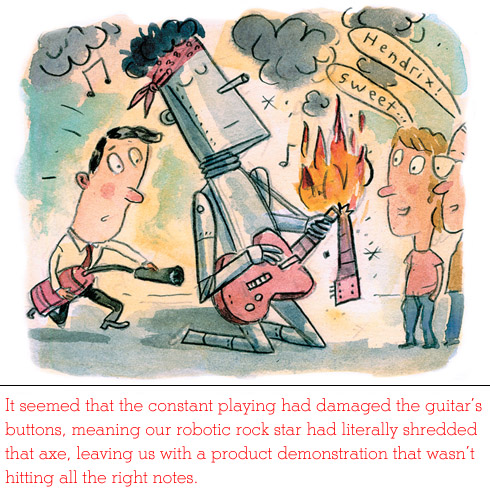

Everything was going great until that afternoon, when our guitar - the electronic game controller that the robot's fingers were repeatedly striking - wore out. It seemed that the constant playing had damaged the guitar's buttons, meaning our robotic rock star had literally shredded that axe, leaving us with a product demonstration that was now hitting all the wrong notes.

This was a disaster. The good news was that the breakdown was with the game's guitar-shaped controller and not our equipment, but the bad news was that we were now without our traffic-building demo. With no "Guitar Hero" robot to draw a crowd, attendees would likely pass by our booth without a second glance. This was a disaster. The good news was that the breakdown was with the game's guitar-shaped controller and not our equipment, but the bad news was that we were now without our traffic-building demo. With no "Guitar Hero" robot to draw a crowd, attendees would likely pass by our booth without a second glance.

We quickly searched through our storage area and discovered that we had a second guitar, but it was not the same make or model as the one that had come with the game. Consequently, all of its keys were out of position with the mounted pneumatic cylinders that actually struck the buttons. This meant someone would need to do some late-night robotics work to get our little robotic rocker up and running in time for day two.

So when the show ended for the day just a few hours after our breakdown, one of my co-workers, DuWayne, took the game, the second guitar, and our automated player home for the night to make the changes and ensure the replacement guitar played properly before the show reopened in the morning.

DuWayne's first order of business was to remove the faulty guitar and get the new guitar securely mounted in the box. Next, he lined up the cylinders for each colored button on the guitar's neck. Finally, and most critically, he adjusted the electronic eye to make sure it sent its signals at the right time and for the right duration for the sensitivity of the replacement guitar's buttons.

The next morning, DuWayne set up the game just like the day before. After a few initial test runs on the show floor, we could see that our traffic-building device was once again strumming the right tune. When attendees started wandering the show floor, our robotic guitar player kept them hanging around our booth like a bunch of groupies hoping for an encore.

After the show, we returned the borrowed guitar player, game, and console to the college students. As a token of our thanks, we gave them the replacement guitar as well as some of our company's automation components to use in their engineering lab. After all, if those students are going to build fun stuff in the lab during their spare time, they should at least have the best parts available.

- Tim Bloudek, director of marketing, Braas Co., Eden Prairie, MN

|

For a company that creates custom industrial-automation solutions, you'd think that setting up an in-booth robot demo would be as easy as greasing a gear. But when our automated attendee gatherer hit a glitch at the 2009 Medical Design & Manufacturing Minneapolis show, it took quick thinking and some engineering wizardry to get our robot once again clicking

on all pneumatic cylinders.

For a company that creates custom industrial-automation solutions, you'd think that setting up an in-booth robot demo would be as easy as greasing a gear. But when our automated attendee gatherer hit a glitch at the 2009 Medical Design & Manufacturing Minneapolis show, it took quick thinking and some engineering wizardry to get our robot once again clicking

on all pneumatic cylinders. This was a disaster. The good news was that the breakdown was with the game's guitar-shaped controller and not our equipment, but the bad news was that we were now without our traffic-building demo. With no "Guitar Hero" robot to draw a crowd, attendees would likely pass by our booth without a second glance.

This was a disaster. The good news was that the breakdown was with the game's guitar-shaped controller and not our equipment, but the bad news was that we were now without our traffic-building demo. With no "Guitar Hero" robot to draw a crowd, attendees would likely pass by our booth without a second glance.