On-Site Construction

Exhibiting in a 10-by-10-foot space at a huge show like the World of Concrete (WOC) can be a bit intimidating. After all, the show floor takes up the whole Las Vegas Convention Center (plus part of its parking area outside) and is covered with exhibits measuring in the thousands of square feet. So I knew my little booth touting my company's drainage system needed to really attract attendees passing by in the aisles. But when my exhibit failed to show up for the expo, I needed to find a way to improvise - or risk getting lost amid the colossal concrete equipment. Exhibiting in a 10-by-10-foot space at a huge show like the World of Concrete (WOC) can be a bit intimidating. After all, the show floor takes up the whole Las Vegas Convention Center (plus part of its parking area outside) and is covered with exhibits measuring in the thousands of square feet. So I knew my little booth touting my company's drainage system needed to really attract attendees passing by in the aisles. But when my exhibit failed to show up for the expo, I needed to find a way to improvise - or risk getting lost amid the colossal concrete equipment.

Just as with most of my trade shows, I planned to fly to Vegas and meet up with my booth, which had been shipped from our home office in Atlanta. With the show set to open at 9 a.m. Tuesday, I arrived at about 10:30 a.m. Monday and headed over to the convention center to take care of my quick setup.

But when I arrived at the convention center, my company's booth was not in my 10-by-10-foot space. After checking with show management to see if my exhibit was in the show hall, I learned that it was missing.

A quick call to our Atlanta office uncovered the problem. The secretary had sent the booth via UPS, as she always did. But when she tracked the package, she discovered that a major snowstorm in the Southeastern United States had delayed my exhibit. In fact, pretty much everything out of Atlanta that weekend had a one-day weather delay. The good news was that it was not completely lost, just tardy. The bad news, though, was that my booth would not arrive until Tuesday afternoon - well into the second day of the four-day show.

With no exhibit and nothing but time on my hands, I sat down and wondered if there was anything I could do until my booth showed up. It was then that the news went from bad to worse. I was approached by someone from Freeman Inc., the company that was running the show for all the construction and concrete associations. It seemed the standard exhibitor's agreement included a clause stating that my booth space had to be filled with some sort of exhibit structure, or else my company would face a fine.

I tried to explain that my exhibit was late, and I'd be able to set it up as soon as it arrived. But the show-services guy was having none of it. He basically told me that if I didn't have a booth, I'd have to pay a fine. Of course, to rent a pop-up exhibit, I'd have to pay as well. It seemed like I was stuck between paying for a replacement booth or paying a fine for not having one at all.

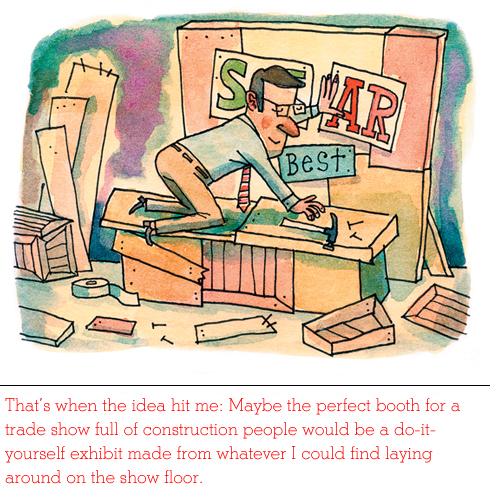

As I watched the other exhibitors putting their booths together, I took note of some of the discarded materials they were tossing into the aisles. The whole situation reminded me of a construction site. Having worked at many such sites, I knew that when you needed a table to work on, you simply built one out of whatever you had lying around. As I watched the other exhibitors putting their booths together, I took note of some of the discarded materials they were tossing into the aisles. The whole situation reminded me of a construction site. Having worked at many such sites, I knew that when you needed a table to work on, you simply built one out of whatever you had lying around.

That's when the idea hit me: Maybe the perfect booth for a trade show full of construction people would be a do-it-yourself exhibit made from whatever I could find laying around on the show floor. It would fit the theme of the show, and save me from renting a booth or paying a fine.

I quickly made a mental list of the items I had, and thought about what else I would need to construct a booth. I knew that my luggage back in my hotel room held some posters that I'd planned to give to our local sales reps. I figured that if I hung those in the exhibit, I'd at least have some graphics. I'd also lugged along a demo version of our drain spout to show attendees how our product worked, and I could display that as well. I even had some product literature to hand out. All of these elements would be perfect booth accessories, but according to the show-services guy, I needed more than accessories - I needed a central structure that acted as a traditional booth.

After a bit of thinking, I decided that my inspiration for this whole solution - i.e., the construction-site table - might just work as a "booth." Thus, I scoured around for something from which I could construct my table. Luckily, I noticed a pair of wooden pallets sitting in the middle of the aisle. No one would need them during the show - and they'd work nicely as the base of my table - so I easily convinced the exhibitors that owned them to let me borrow them for the duration of the show.

Next, I needed something to hold my makeshift table together. Fortunately, a few aisles over was a company called Intertape Polymer Group Inc., which sells adhesives for all kinds of applications. Having spotted them earlier, I wandered over and told the Intertape folks about my problem. They gladly loaned me all the tape I would need.

Back in my exhibit space, I set the pallets up on their sides and used the tape to join them at a 90-degree angle, turning the pallets into the legs of my table. Next, I found a nice big square of sturdy cardboard in a nearby aisle that was about to be thrown away. I dragged it back to my booth where I laid it across the pallets and taped it down to create a tabletop. Finally, I rushed back to my hotel room and grabbed my "graphics" and accessories. Then back at the booth, I used my tape to affix the posters to the pipe-and-drape back wall. When the show-services guy walked by again, he gave his OK for my do-it-yourself structure.

As soon as I was done with setup, I headed back to my hotel room and went to bed, hoping my makeshift booth would hold up, at least until my real exhibit arrived. But when the show opened the next morning, I was in for a real surprise. It seemed my improvised table was a hit with the construction-centric audience, drawing attendees in from the aisle to talk about my inventiveness. And once I had them chatting, I was easily able to segue into a conversation about my company's drainage system.

In fact, when my real exhibit arrived later that afternoon, I decided to let it sit in its case until the show closed. People loved the nontraditional booth. Based on the traffic I got and the great leads I gathered, by show's end I realized that my pallet-and-cardboard structure was the best exhibit I'd ever had.

By show's end, I talked to more than 200 people, a huge number for my company, and had a great show. It seems that a snowstorm and a little creativity helped me stand out from the concrete crowd after all.

- Haynes Sloan, vice president of product design, Invisa Flow LLC, Gallatin, TN

|

Exhibiting in a 10-by-10-foot space at a huge show like the World of Concrete (WOC) can be a bit intimidating. After all, the show floor takes up the whole Las Vegas Convention Center (plus part of its parking area outside) and is covered with exhibits measuring in the thousands of square feet. So I knew my little booth touting my company's drainage system needed to really attract attendees passing by in the aisles. But when my exhibit failed to show up for the expo, I needed to find a way to improvise - or risk getting lost amid the colossal concrete equipment.

Exhibiting in a 10-by-10-foot space at a huge show like the World of Concrete (WOC) can be a bit intimidating. After all, the show floor takes up the whole Las Vegas Convention Center (plus part of its parking area outside) and is covered with exhibits measuring in the thousands of square feet. So I knew my little booth touting my company's drainage system needed to really attract attendees passing by in the aisles. But when my exhibit failed to show up for the expo, I needed to find a way to improvise - or risk getting lost amid the colossal concrete equipment.  As I watched the other exhibitors putting their booths together, I took note of some of the discarded materials they were tossing into the aisles. The whole situation reminded me of a construction site. Having worked at many such sites, I knew that when you needed a table to work on, you simply built one out of whatever you had lying around.

As I watched the other exhibitors putting their booths together, I took note of some of the discarded materials they were tossing into the aisles. The whole situation reminded me of a construction site. Having worked at many such sites, I knew that when you needed a table to work on, you simply built one out of whatever you had lying around.