| ALL-STAR |

Deanna Aamodt, manager of global event management services at Thomson Reuters Corp., has 20 years of exhibit and event experience, and has executed more than 600 events in her current role. Deanna Aamodt, manager of global event management services at Thomson Reuters Corp., has 20 years of exhibit and event experience, and has executed more than 600 events in her current role. |

part from their ability to sell us products and services, most of the world's top companies excel in another critical area: brand identity. We all know a red bull's-eye means Target Corp., a swoosh means Nike Inc., and a slightly insane, bouncing smiley face means Wal-Mart Stores Inc. is rolling back prices. Although each of these companies sell their products at thousands of locations worldwide, they foster cohesive brand identities that are easily recognizable to consumers across the globe. But when your company encompasses multiple business lines and products with vastly different audiences around the world, putting together a unified brand image can easily become more difficult than solving a Rubik's Cube.

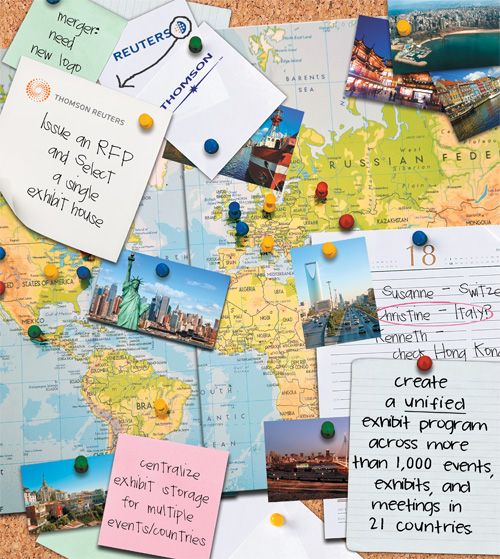

Just ask Thomson Reuters Corp., a New York-based news, information, and service provider. The company employs more than 60,000 people, operates in 100-plus countries, and has divisions that provide services to the media, legal, financial, tax, science, and health-care industries. Thomson Reuters was formed by Thomson Corp.'s purchase of Reuters Group in April 2008, and since that time has acquired an astounding 16 companies.

Although by 2009 Thomson Reuters was officially listed and operating as one unit, its genesis from mergers and acquisitions had left its trade show presence with an identity crisis. "We are a global company that does trade shows all over the world, and we were finding that if you were in Asia, we looked like one company, and if you were in the United States, we looked like a completely different company," says Deanna Aamodt, global event project manager for Thomson Reuters. "For a long time we were run as individual business units, not as Thomson Reuters."

Desperately Seeking Solutions

In 2010, Thomson Reuters' identity crisis became Aamodt's biggest challenge. The company handed her the daunting task of piecing together a unified exhibit program across more than 1,000 events, exhibits, and sales meetings the company attends annually in 21 countries.

With a marketing mess and a thin pocketbook thanks to the economic downturn, Aamodt knew she needed some Herculean help to revamp Thomson Reuters' trade show program without breaking the bank. "The first thing we found was that our company was working with multiple exhibit houses, and it was going to be really hard to rebrand and get a global look and feel with so many hands in the pot," Aamodt says.

So in mid-2010, the company put out a request for proposal to select a single marketing firm to overhaul its trade show program. Among those firms responding to the RFP was Chicago-based 3D Exhibits Inc., which had worked with Thomson Reuters on smaller exhibit projects in 2009. "During that time, we identified a number of issues in Thomson Reuters' exhibiting program, including a lack of brand consistency and no real means to manage and share inventory across the globe," says Nelson Corazzari, 3D's senior vice president and account executive.

That insight helped the company put together a winning proposal to reinvent Thomson Reuters' exhibiting program via three key objectives: 1) consolidate and unify the company's global exhibiting program, 2) implement technology to manage, track, and analyze inventory, and 3) facilitate communications and idea sharing across the global marketing team.

With such a colossal project ahead, Aamodt knew that good leadership was critical to its success, so she assembled a six-member global executive committee to provide guidance throughout what became a nearly two-year undertaking. The committee consisted of upper-level Thomson Reuters' executives and met monthly to review the plan and ensure everyone was on board.

Global Garbage Pile

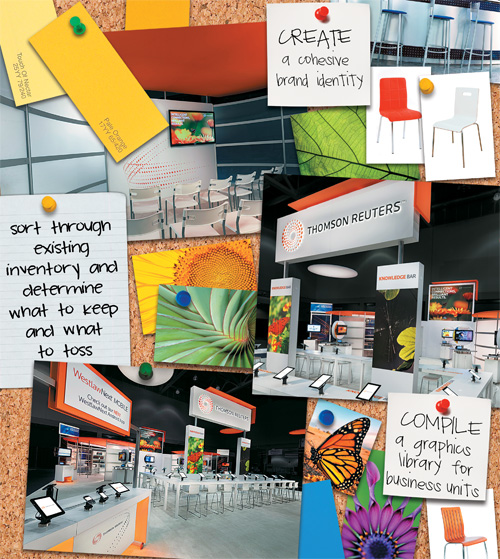

The project kicked off in October 2010 with a grueling year-long review of the company's existing exhibit properties, inventories, and suppliers. "We needed to figure out what we had, what we could keep, what we needed to trash, and where to go from there," Aamodt says. To accomplish this, Aamodt dispatched a team of eight from 3D to pick through a jumbled mess of exhibit properties accumulated by Thomson Reuters' trade show staff around the world. "Because Thomson Reuters had gone through so much acquisition and expansion, there was no consistency in its global inventory," Corazzari says. "Thomson branding was traditionally blue while Reuters was orange. They had everything under the sun."

3D gathered ragtag pieces of existing inventory in 10 warehouses worldwide. These locations were selected to serve as supply depots for Thomson Reuters' exhibit program moving forward. "We looked at where most of our shows fall, and which ones occur in the same spot every year. We wanted to set up supply depots near those locations to help reduce shipping costs," Aamodt says. "We then looked at storage costs in those areas. For example, it's very expensive to have warehouse space in France, so it might be a cheaper option to ship from a country nearby."

Locations secured, 3D assessed the existing pieces and reached a grim conclusion. Instead of stockpiles full of salvageable treasures, on-hand inventory looked more like piles of junk. "A lot of these assets had not been taken care of," Corazzari says. "Plus, construction methods for many of the pieces were not what they are today. You had a lot of heavy plywood structures and outdated pieces that couldn't be easily repurposed."

"We had to decide whether an existing structure was worth fixing, or whether it was just cheaper to replace," Aamodt says. In the end, Thomson Reuters discarded or recycled 75 percent of its existing exhibiting materials. But before Thomson Reuters could invest in new properties, it needed to nail down a branding scheme that would become the face of the company worldwide.

Working with creative resources at Thomson Reuters and 3D, Aamodt and her team developed a sleek and simple design platform that incorporated Reuters' signature orange with a muted gray color scheme, and featured the Thomson Reuters' name and circular, orange brand logo. And that was it. Keeping the building blocks simple would allow the business areas to customize details within the booths to market their products while still maintaining a single, cohesive brand aesthetic.

Purchase with Purpose

When the company began purchasing new properties in spring 2011, it kept this concept in mind while also looking for opportunities to reduce exhibiting costs. "Our purchases focused on easy-to-assemble, lightweight materials to help us reduce shipping and labor costs," Aamodt says. A key component of the new design turned out to be a fairly simple one: fabric wall panels. Apart from being cheap and less expensive to ship, they also allowed the flexibility in design that Thomson Reuters needed to support its diverse business lines. "Our creative team developed a library of images that business lines could print on these walls, allowing them to customize booths to their specific products and regions," Aamodt says.

Lessons learned from the review of existing inventory also influenced Thomson Reuters' purchasing strategy. After having to discard a number of large, custom properties that couldn't be easily repurposed, the company looked to rent, not buy, when it came to big-scale, big-ticket items. "When you use rentals, you don't have to pay storage," Aamodt says. "And, if it's damaged, it's the supplier's problem, not ours, helping us save on maintenance costs."

By choosing rental for large pieces, Thomson Reuters also avoided having to use the same layout year after year to get a return on the sizeable investment of a custom-built structure. "Using rentals, we aren't tied to that same exhibit for five years," Aamodt says. "And by keeping our design simple, we can easily create new looks with lighting and graphics to keep things fresh."

Tools of the Trade Show

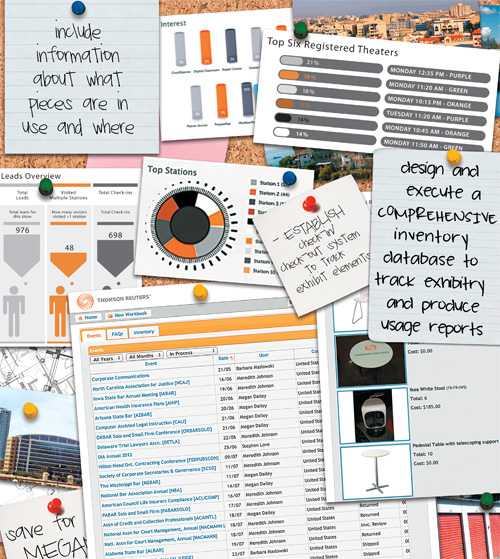

As cleanup of its existing exhibiting supplies progressed and new materials started coming in, Thomson Reuters worked with 3D to implement new technology to track and manage that inventory. "A big problem for us in the past was that nobody knew what exhibiting properties or supplies each area of our company was using or had available for others to use," Aamodt says. 3D took note of that problem during its review of existing inventory. "As we sorted through the inventory, we found that the entire program tended to operate inefficiently. They were constantly remaking things, and a lot of business units had multiples of the same items but didn't even know it," Corazzari says.

So in early 2011, Thomson Reuters implemented an online system that trade show staff could use to view, reserve, and track inventory. The Web-based system allows approximately 40 Thomson Reuters' team members to log in from anywhere in the world. By entering the date and location for a show they're planning, they're automatically directed to view photos and quantities of available inventory at the nearest supply depot. Built-in, drag-and-drop templates let them design a virtual floor plan using that inventory. When they've got what they need, they simply check out those supplies for the show dates. The system automatically reserves that inventory so it can be shipped and on hand for the show, and removes it from global availability for those dates. If the nearest supply depot for the show doesn't have what they need, staff members can view global supplies as well.

"In addition to inventory management, the tool also provides a dashboard that lets us see details on all the shows and events planned company wide," Aamodt says. "This way, if I'm doing a show in China and someone else is doing a show nearby around the same time, we can look for opportunities to collaborate, reuse setups, and transfer supplies instead of building from scratch and shipping from the warehouse for each event."

Access to this treasure chest of exhibiting supplies has proven especially helpful for Thomson Reuters' business lines with smaller budgets. "Every business unit across Thomson Reuters is sharing inventory with this system," Corazzari says. "If someone builds something new, it goes into the system. That gives all users a huge inventory of existing supplies to choose from, which saves money by eliminating duplicate purchases and unnecessary builds."

But the perks of this tool don't stop there. Built-in reporting capabilities help administrative users like Aamodt further manage global supplies. "I get a semi-annual report that shows what inventory has been used and what's sat idle. From there, we can decide if we need to keep storing these items or trash them. By eliminating what we don't use, we cut out additional storage costs." Additional reporting features include automated notifications when supplies haven't been returned and checked back into the system within two weeks of a show's end date.

In mid-2011, a series of Web-based trainings rolled out the completed system to Thomson Reuters' global trade show staff. "The overwhelming feedback from our staff was that it was giant relief to finally have control of our inventory in one centralized system," Aamodt says.

Information Infrastructure

In addition to the new tool, Thomson Reuters developed a communications and information-sharing infrastructure for its global trade show team. Aamodt established a quarterly newsletter that's posted to the site and full of information on recent exhibiting within the company to inspire the team and keep it abreast of activities across the globe.

The newsletter also spotlights upcoming exhibiting, which has proven useful in planning. "In some countries, we run into what we call build and burns," Aamodt says. "This is when, due to shipping and other logistical costs in those areas, we set something up for one-time use and end up discarding most of it. Because we could share information like this, we were able to reuse display materials from a show in Dubai for a geographically adjacent event instead of simply discarding them." Along with these tools, Aamodt implemented semi-annual event-strategy meetings where the executive team originally created for the project reviews the strategic direction of Thomson Reuters' revamped exhibiting program.

A Brand Reborn

By 2012, Thomson Reuters emerged from a sea of acquisitions and the clutter of a disjointed exhibit program as a brand reborn. Armed with an arsenal of tools, a revamped inventory, and a solid internal infrastructure, the company debuted its new, unified signature brand style at the American Association of Law Libraries Meeting and Conference in July 2012. To measure the impact of the rebrand, Thomson Reuters plans to survey customers in 2013 to gauge brand recognition. "We want to make sure people are coming away from events knowing who we are," Aamodt says.

While those results are pending, other indicators have already provided tangible proof that the massive undertaking was well worth the effort. "Despite a $500,000 budget cut in 2011, we were able to maintain our exhibiting and event schedule," Aamodt says. She also estimates the program overhaul is saving Thomson Reuters $100,000 annually thanks to a 16-percent reduction in the company's storage footprint from inventory consolidation and improved utilization of existing supplies.

"With shrinking budgets and constant reorganizations, this submission is a great global example of how to consolidate a trade show program," one All-Star Awards judge said. "To reduce costs, properties, and warehouse charges while in the process aligning the organization to have a global unified look is extremely powerful."

Aamodt credits the success of the project to Thomson Reuters' partnership with 3D, saying, "I am a firm believer that you are only as good as your team, and without that partnership, I don't think we could have pulled this off."

3D was equally impressed with Aamodt and the Thomson Reuters' team. "We made some very aggressive recommendations, and Thomson Reuters was consistently open to them and willing to examine and reshape how it worked," Corazzari says. "Some companies are so stuck in how they think that they never do anything new."

Aamodt continues to work with 3D on improvements, including portable device compatibility for the inventory-management system and implementation of lead-tracking software and metrics throughout the exhibit program. Given these plans, it seems one judge's comment that Aamodt "will be saving the company a lot more than the $500,000 in the long run" is right on the money. E

|

Deanna Aamodt,

Deanna Aamodt,