atagonia Inc. has been Green almost as long as the exotic and unspoiled region of South America the outdoor-apparel retailer is named after. Even the mission statement of the Ventura, CA-based company founded in 1972 is good for the earth: “To build the best product, to cause the least harm, and to use business to inspire and implement solutions to the environmental crisis.” atagonia Inc. has been Green almost as long as the exotic and unspoiled region of South America the outdoor-apparel retailer is named after. Even the mission statement of the Ventura, CA-based company founded in 1972 is good for the earth: “To build the best product, to cause the least harm, and to use business to inspire and implement solutions to the environmental crisis.”

That’s not just a bunch of corporate blather filling the air like smog during rush hour in LA, either. The company commits at least 1 percent of sales or 10 percent of pre-tax profits — whichever is greater — to environmental groups, donating more than $30 million to more than 1,000 organizations since 1985. Furthermore, all of its cotton products are made from 100-percent organically grown cotton, its fleece comprises fabric manufactured from recycled water bottles, and 12 percent of its Ventura headquarters’ electricity comes from solar panels. The company even boasts a vice president of marketing and environmental initiatives, and its Common Threads program encourages customers to return their Patagonia underwear and other clothes to be recycled at the end of their useful life.

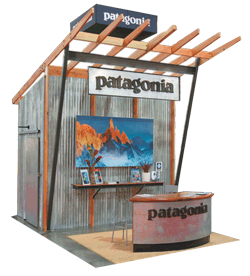

That’s why Patagonia enlisted the help of Atmosphere Studios LLC to help it design a kinder, Greener booth to debut at the Outdoor Retailer Show Winter Market in 2006.

FAST FACT

Twelve percent of the energy required to power Patagonia’s Ventura, CA, headquarters comes from solar panels. |

|

|

For a company where Green is as deeply embedded in everything as chlorophyll is in plants, its trade show booth lagged a few years behind Patagonia as a whole: It was a hodgepodge of laminates and some earth-unfriendly materials along with a few Green items. While not exactly as bad for public relations as an oil spill in a protected wetland, the exhibit clashed with the mission statement of the Greener-than-thou Patagonia brand.

“Patagonia wanted its exhibit to be in synch with its Greened corporate culture,” says Tom Jennings, a designer at Salt Lake City-based Atmosphere. For some companies, that would mean little more than a couple boards of Plyboo and a recycling bin. For Patagonia, the mandate was as important as its showdown decision in 1994 when founder Yvon Chouinard gave his company 18 months to switch to organic cotton — a ballsy move, considering cotton products accounted for a fifth of Patagonia’s business. But Chouinard did it simply because regular cotton was so full of pesticides (the crop consumes less than 3 percent of farmed land globally but eats up about a quarter of all pesticides sprayed) that he believed wearing anything made of it was like taking a hit off a bong full of DDT.

But this was not the first time Patagonia had taken eco-friendly action with regard to its exhibit-marketing efforts. In 2005, the company stopped using regular carpet in its trade show booths and replaced it with recycled sisal area rugs. The company also started using Douglas Fir wood reclaimed from old barns, as well as recycled galvanized metal for the exhibit’s wall panels.

But going Green is far from a one-and-done process: It’s an ongoing evolution of fixes and adjustments, of trade-offs among price and quality and availability. “That old booth was a good start,” Jennings says, “but like its clothing, Patagonia wanted to go

the extra step.”

Green Isn’t Grungy

|

FAST FACT

Cold-rolled steel requires less energy to manufacture than hot-rolled steel and has a higher strength-per-weight ratio. |

|

Not only did Patagonia want to expand its reputation as a Green-as-grass company in a way it could measure, it wanted to increase its presence on the show floor as well. So instead of the 30-by-70-foot exhibit it had in 2005, the company wanted its new booth to measure 40-by-80 feet with a 500-square-foot mezzanine, an increase in overall square footage of slightly more than 75 percent. But that meant the booth would now have an enlarged ecological footprint, too.

To shrink it, Patagonia and Atmosphere started with the most basic — and easiest — of Green practices: recycling. Whatever the final redesign of the booth would be, they would reuse the previous exhibit’s reclaimed wood, sisal area rugs, and recycled metal, as well as an antique reception desk that Patagonia staffers had found and restored to its original luster. “We salvaged everything we could from the old booth,” Jennings says.

But Atmosphere knew that the recycled materials couldn’t mean a hand-me-down look. So it devised a two-story design with a mezzanine using these recycled elements as the core and featuring a mountain-village theme that was larger, yet Greener than the previous booth.

For the mezzanine and overhead treatments, Patagonia used reclaimed wood as well as cold-rolled steel, which requires less energy to manufacture than the standard hot-rolled version, adding to its desirability. Not only was the steel made from 50-percent recycled metal, its high strength-per-weight ratio meant the company needed less of it than it would aluminum or wood, which translated into several hundred pounds that Patagonia wouldn’t have to ship in diesel-powered tractor-trailers, ultimately preventing hundreds of pounds or more of CO² from poisoning the air. It

was one of the Greenest moves Patagonia could make, since diesel emissions pose the greatest cancer risk of air pollutants, according to environmental watchdog site www.Scorecard.org.

FAST FACT

According to www.Scorecard.org, diesel emissions pose the greatest cancer risk of all air pollutants. |

|

|

Inside the booth, the miniature shops were framed in the rustic, reclaimed barn wood, each accented with a different product line, from Patagonia’s fleece jackets to its cold-weather hats. Arranged on racks and shelves built from reclaimed wood, the products were lit by 75-watt halogen bulbs. Patagonia reduced the number of fixtures by about half from the 2005 booth to save energy and to “focus on the products like a diamond in a Tiffany’s window,” Jennings says.

Instead of carpeting, visitors trod on the plain cement floor, whose bare surface was occasionally broken by the sisal rugs. The upstairs mezzanine offered a cabin-in-the-woods simplicity of plain plywood and a few sisal rugs, as well.

Going the Last Green Mile

While Patagonia’s Web site offers the interactive Footprint Chronicles, where customers can track the carbon footprint of Patagonia products from design through delivery, the booth is still a few steps behind, as no such capability exists yet for its exhibits. Still, the 2006 booth established a rough baseline as well as a blueprint for finding Greener materials and measuring their impact.

Patagonia plans to continue reusing the existing booth, recycling the wood, metal, and rug components, and keep new construction to a minimum, relying on easy-to-transport graphics and low-VOC paints to make seasonal color shifts and maintain a fresh look. “Patagonia didn’t just jump on the Green train,” Jennings says. “It’s willing to take years to Green a product — or a booth.”

The company understands what others are just learning

— that going Greener is like reforesting the Patagonia

region itself, a process that’s never done, but whose success is judged by your commitment over time to evolving and perfecting your approach.

|

SMALL AND SUSTAINABLE

You don’t have to go big to go Green. In fact, small booths are some of the Greenest exhibits going. Small 10-by-10-foot exhibits eat up fewer natural resources in their construction, their light weight nature means less energy is used for shipping, and they add less volume to landfills. These three small exhibits use everything from Eco-Resin panels to recycled aluminum to give a polite but powerful nod to Mother Nature.

Green Baggin’ It Green Baggin’ It

Ecobags’ modular exhibit, designed by Go Green Displays, comprises recycled aluminum, graphics printed on fabric made from recycled yarn, and LEDs. The flooring is made of recycled rubber tires and packs into cases made of recycled plastic and filled with biodegradable packing material.

All Bamboo, All the Time All Bamboo, All the Time

Aptly named the Bambooth, this exhibit is about as Green as they come. Created for and sold by Green Events Source, this snazzy 10-by-10 features a bamboo frame, Eco-Resin panels, natural or no-VOC finishes, and graphics printed with vegetable-based inks.

Eco-Logical Eco-Logical

Designed by Eco-Systems Sustainable Exhibits Inc., this booth for Clothing Matters features eco-friendly graphics made with water-based ink and Paradise Fabric using 100-percent recycled content. The booth also includes a dressing room where attendees can try on the exhibitor’s natural-fiber fabrics. |