green exhibiting |

|

he most popular color at The Sherwin-Williams Co. isn’t Grape Mist or Cherries Jubilee. It’s Green. For 142 years, the Cleveland-based coatings manufacturer for the commercial, industrial, and consumer markets has lived up to its slogan, Cover the Earth, by identifying markets for its products from railroad cars and farms to homes and stadiums. So when the company launched the earth-friendly GreenSure designation for its coatings that meet or exceed the standards set by the USGBC for LEED-certified buildings, it wasn’t just varnishing its image; it was entering one of the hottest market segments in the $20 billion paint and coating industry. In fact, the demand for eco-friendly paint is spreading so fast that according to Green Seal, a Washington, DC-based nonprofit group that certifies products and services, the number of Green paints has more than doubled in the past four years. he most popular color at The Sherwin-Williams Co. isn’t Grape Mist or Cherries Jubilee. It’s Green. For 142 years, the Cleveland-based coatings manufacturer for the commercial, industrial, and consumer markets has lived up to its slogan, Cover the Earth, by identifying markets for its products from railroad cars and farms to homes and stadiums. So when the company launched the earth-friendly GreenSure designation for its coatings that meet or exceed the standards set by the USGBC for LEED-certified buildings, it wasn’t just varnishing its image; it was entering one of the hottest market segments in the $20 billion paint and coating industry. In fact, the demand for eco-friendly paint is spreading so fast that according to Green Seal, a Washington, DC-based nonprofit group that certifies products and services, the number of Green paints has more than doubled in the past four years.

|

FAST FACT

The demand for eco-friendly paint is spreading so fast that the number of Green paints has more than doubled in four years. |

|

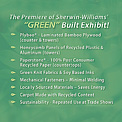

But while Sherwin-Williams was Greening its products, the coatings manufacturer painted itself into a corner with its old 20-by-20-foot exhibit. “Sherwin-Williams has zero- and low-VOC paints, its GreenSure designation, and many Green Initiatives, but it didn’t have a booth that could promote that,” says Tresa Makowski, the company’s director of trade communications. “Since our exhibit messaging is targeted to the building and construction industries that are building Green, it seemed like the perfect opportunity to ‘build Green’ ourselves,” she says, adding, “We looked at the old exhibit and said ‘How can we do this better?’”

Working with Opus Design Inc. a division of Gallo Display Inc., both of Cleveland, Sherwin-Williams decided on a 20-by-20-foot island booth that was as simple as a primary color. Opus purchased most materials for it locally to reduce greenhouse gas emissions from shipping, then integrated them into a design that went beyond the usual Green elements. For example, Sherwin-Williams used mechanical fasteners on the three tower-like product stations made of recycled plastic and aluminum — a move that allowed the company to nearly eliminate welding, which produces gases such as carbon dioxide.

The company also swapped out ecologically

unfriendly elements for Greener alternatives. For example, in place of plywood for the counters and towers, the new booth used Plyboo. Instead of laminate for the counters, it employed Paperstone, a material made of 100-percent post-consumer waste paper and petroleum-free resin. The flooring was a polyethylene terephthalate (PET) recycled carpet made of yarn created from reclaimed soda bottles. Graphics were printed on Green fabrics and Plyboo panels with a soy-based ink, which makes paper recycling easier because soy ink can be removed quicker than regular petroleum-based ink, and biodegrades four times as thoroughly.

|

|

The exhibit’s three towers, made from

Plyboo, were

assembled with mechanical

fasteners made of recycled

plastic and

aluminum.

|

In the end, though, you are only as Green as your audience perceives you to be. So, to promote the exhibit’s and Sherwin-Williams’ eco-friendliness at its debut at the American Institute of Architects (AIA) National Convention and Design Exposition in Boston last May, the company positioned lime-green signs on each station explaining the ways it reduced the booth’s carbon footprint. Staffers also emphasized the booth’s Green features by infusing its eco-friendly attributes into conversations with attendees.

FAST FACT

Soy-based ink can be removed quicker than petroleum-based ink, and biodegrades four times as thoroughly. |

|

|

Finally, in a behind-the-scenes move that was among the most eco-friendly of them all, Sherwin-Williams chose to pad wrap its exhibit components rather than build seven standard wood crates, which Opus estimates would have added as much as 2,100 pounds to the 5,000-pound booth. The nearly 40-percent increase in weight would have meant a corresponding increase in the amount of CO² emitted when Sherwin-Williams shipped the booth.

Additionally, instead of shipping the exhibit back to Cleveland after each of the four shows Sherwin-Williams plans to exhibit at this year, the company will store the exhibit in the host-city show contractor’s warehouse or its transportation company’s closest facility and then transport it directly from show to show. Based on the Greenhouse Gas Protocol formulas from the World Resources Institute and the World Business Council for Sustainable Development, by the time it concludes its exhibiting schedule for 2008, that tactic will have prevented an estimated 5,529 pounds of greenhouse gases from fouling the air, proving that what Sherwin-Williams did to Green its booth was much more than just a pigment of its imagination.

|

|

|

|

|

To communicate its move toward Greener exhibiting practices, The Sherwin-Williams Co. placed signs throughout its booth that outlined the exhibit’s eco-friendly materials.

|

Rather than using conventional plywood for the counter tops and towers in its exhibit, the company opted for Plyboo, a more sustainable alternative derived from bamboo.

|

In lieu of synthetic carpet,

the exhibit’s floor was covered using polyethylene terephthalate (PET) recycled carpet, made from reclaimed plastic bottles. |

Instead of transporting

its exhibit property back

to Cleveland after each

trade show, Sherwin-

Williams stores its booth

at a warehouse in the show’s host city. |

| |

MOTHER NATURE'S HIT LIST

Do you know which exhibit materials are the worst eco-offenders, and do you know why they’re on Mother Nature’s hit list? Tim Morris, president of Grand Rapids, MI based Eco-Systems Sustainable Exhibits Inc., exposes four of the most eco-unfriendly materials widely used in the exhibit industry. While you might not be able to eliminate all of these troublemakers immediately, simply removing one of these eco-villains is a good first step in the right direction. Do you know which exhibit materials are the worst eco-offenders, and do you know why they’re on Mother Nature’s hit list? Tim Morris, president of Grand Rapids, MI based Eco-Systems Sustainable Exhibits Inc., exposes four of the most eco-unfriendly materials widely used in the exhibit industry. While you might not be able to eliminate all of these troublemakers immediately, simply removing one of these eco-villains is a good first step in the right direction.

1. Polyvinyl Chloride (PVC) — Typically found in exhibit graphics and wall structures, PVC is often sold under the brand name Sintra. Simply manufacturing this thermoplastic polymer creates and releases the toxic chemical dioxin. Plus, PVC is not biodegradable, and it can leak harmful additives into the air or ground when it’s burned or buried. Morris urges exhibitors to eliminate PVC entirely, replacing it with a similar material such as ReCo. At the very least, keep PVC use to a bare minimum and reuse and recycle as much of it as possible.

2. Particle Board — Most particle board, fiberboard, and plywood products that use glue as part of their manufacturing processes likely contain and release urea formaldehyde, a VOC classified by the EPA as a Probable Human Carcinogen. These products are often covered with laminates, which provide a barrier preventing the material from off gassing. However, the formaldehyde still escapes from unfinished surfaces and edges. “Plus, as the materials biodegrade, they produce methane gas, which is 10 times more potent than your typical greenhouse gas in terms of the amount of damage it does to the environment,” Morris says. He suggests coating all of these surfaces with a low-VOC sealant, such as AFM Safe Seal, or better yet, replace these products with formaldehyde-free pressed wood or MDF certified by the FSC.

3. Adhesives — Just about every exhibit is manufactured using some type of adhesive. While water-based glue generally isn’t a problem, petroleum- or solvent-based adhesives emit a high level of VOCs, which cause various health issues. Morris proposes you request that your exhibit house use no- or low-VOC adhesives, which tend to be of the water-based variety, such as Eco-Bond, Adhesin, or even Elmer’s Carpenter’s Glue.

4. Synthetic Carpet — Petroleum-based carpet is a toxic soup of sorts, as toxins can be found in everything from its dyes and backing glues to its stain-resistant treatments. Plus, almost all synthetic carpet takes roughly 100 years to degrade. And given the enormous amount of carpet the industry uses, Morris asserts that use of synthetic exhibit carpet is one of the industry’s biggest environmental sins. He suggests pairing the convention-center concrete with a few throw rugs in your exhibit, or using products such as cork, sisal, or sea-grass mats that biodegrade faster and contain fewer toxins than traditional carpet.

|

|

|

|

|